A rocket engine uses stored rocket propellants as the reaction mass for forming a high-speed propulsive jet of fluid, usually high-temperature gas. Rocket engines are reaction engines, producing thrust by ejecting mass rearward, in accordance with Newton's third law. Most rocket engines use the combustion of reactive chemicals to supply the necessary energy, but non-combusting forms such as cold gas thrusters and nuclear thermal rockets also exist. Vehicles propelled by rocket engines are commonly called rockets. Rocket vehicles carry their own oxidizer, unlike most combustion engines, so rocket engines can be used in a vacuum to propel spacecraft and ballistic missiles.

The expander cycle is a power cycle of a bipropellant rocket engine. In this cycle, the fuel is used to cool the engine's combustion chamber, picking up heat and changing phase. The now heated and gaseous fuel then powers the turbine that drives the engine's fuel and oxidizer pumps before being injected into the combustion chamber and burned.

A liquid-propellant rocket or liquid rocket utilizes a rocket engine that uses liquid propellants. Liquids are desirable because they have a reasonably high density and high specific impulse (Isp). This allows the volume of the propellant tanks to be relatively low. It is also possible to use lightweight centrifugal turbopumps to pump the rocket propellant from the tanks into the combustion chamber, which means that the propellants can be kept under low pressure. This permits the use of low-mass propellant tanks that do not need to resist the high pressures needed to store significant amounts of gases, resulting in a low mass ratio for the rocket.

The J-2 was a liquid-fuel cryogenic rocket engine used on NASA's Saturn IB and Saturn V launch vehicles. Built in the U.S. by Rocketdyne, the J-2 burned cryogenic liquid hydrogen (LH2) and liquid oxygen (LOX) propellants, with each engine producing 1,033.1 kN (232,250 lbf) of thrust in vacuum. The engine's preliminary design dates back to recommendations of the 1959 Silverstein Committee. Rocketdyne won approval to develop the J-2 in June 1960 and the first flight, AS-201, occurred on 26 February 1966. The J-2 underwent several minor upgrades over its operational history to improve the engine's performance, with two major upgrade programs, the de Laval nozzle-type J-2S and aerospike-type J-2T, which were cancelled after the conclusion of the Apollo program.

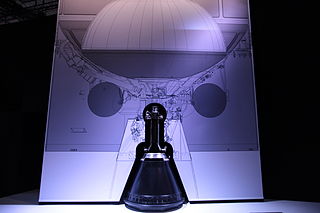

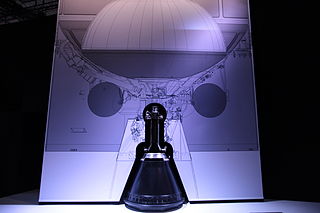

The RL10 is a liquid-fuel cryogenic rocket engine built in the United States by Aerojet Rocketdyne that burns cryogenic liquid hydrogen and liquid oxygen propellants. Modern versions produce up to 110 kN (24,729 lbf) of thrust per engine in vacuum. Three RL10 versions are in production for the Centaur upper stage of the Atlas V and the DCSS of the Delta IV. Three more versions are in development for the Exploration Upper Stage of the Space Launch System and the Centaur V of the Vulcan rocket.

The staged combustion cycle is a power cycle of a bipropellant rocket engine. In the staged combustion cycle, propellant flows through multiple combustion chambers, and is thus combusted in stages. The main advantage relative to other rocket engine power cycles is high fuel efficiency, measured through specific impulse, while its main disadvantage is engineering complexity.

Vulcain is a family of European first stage rocket engines for Ariane 5 and the future Ariane 6. Its development began in 1988 and the first flight was completed in 1996. The updated version of the engine, Vulcain 2, was first successfully flown in 2005. Both members of the family use liquid oxygen/liquid hydrogen cryogenic fuel. The new version under development for Ariane 6 will be called Vulcain 2.1.

Vinci is a European Space Agency cryogenic liquid rocket engine currently under development. It is designed to power the new upper stage of Ariane 6.

The YF-75 is a liquid cryogenic rocket engine burning liquid hydrogen and liquid oxygen in a gas generator cycle. It is China's second generation of cryogenic propellant engine, after the YF-73, which it replaced. It is used in a dual engine mount in the H-18 third stage of the Long March 3A, Long March 3B and Long March 3C launch vehicles. Within the mount, each engine can gimbal individually to enable thrust vectoring control. The engine also heats hydrogen and helium to pressurize the stage tanks and can control the mixture ratio to optimize propellant consumption.

The YF-77 is China's first cryogenic rocket engine developed for booster applications. It burns liquid hydrogen fuel and liquid oxygen oxidizer using a gas generator cycle. A pair of these engines powers the LM-5 core stage. Each engine can independently gimbal in two planes. Although the YF-77 is ignited prior to liftoff, the LM-5's four strap-on boosters provide most of the initial thrust in an arrangement similar to the European Vulcain on the Ariane 5 or the Japanese LE-7 on the H-II.

Chemical Automatics Design Bureau (CADB), also KB Khimavtomatika, is a Russian design bureau founded by the NKAP in 1941 and led by Semyon Kosberg until his death in 1965. Its origin dates back to a 1940 Moscow carburetor factory, evacuated to Berdsk in 1941, and then relocated to Voronezh city in 1945, where it now operates. Originally designated OKB-296 and tasked to develop fuel equipment for aviation engines, it was redesignated OKB-154 in 1946.

The LE-5 liquid rocket engine and its derivative models were developed in Japan to meet the need for an upper stage propulsion system for the H-I and H-II series of launch vehicles. It is a bipropellant design, using LH2 and LOX. Primary design and production work was carried out by Mitsubishi Heavy Industries. In terms of liquid rockets, it is a fairly small engine, both in size and thrust output, being in the 89 kN (20,000 lbf) and the more recent models the 130 kN (30,000 lbf) thrust class. The motor is capable of multiple restarts, due to a spark ignition system as opposed to the single use pyrotechnic or hypergolic igniters commonly used on some contemporary engines. Though rated for up to 16 starts and 40+ minutes of firing time, on the H-II the engine is considered expendable, being used for one flight and jettisoned. It is sometimes started only once for a nine-minute burn, but in missions to GTO the engine is often fired a second time to inject the payload into the higher orbit after a temporary low Earth orbit has been established.

A cryogenic rocket engine is a rocket engine that uses a cryogenic fuel and oxidizer; that is, both its fuel and oxidizer are gases which have been liquefied and are stored at very low temperatures. These highly efficient engines were first flown on the US Atlas-Centaur and were one of the main factors of NASA's success in reaching the Moon by the Saturn V rocket.

The RD-0146 is a Russian cryogenic rocket engine. The RD-0146 engine was developed by KBKhA design bureau in Voronezh, Russia, in cooperation with the American Pratt & Whitney Rocketdyne company. In 2009, it came into prominence, as Russian space agency chose it for the second-stage of the proposed Rus-M launch vehicle designed to carry the future Russian PPTS crewed spacecraft. After the cancellation of Rus-M rocket, the RD-0146D variant was selected as the powerplant for the KVTK upper stage.

The LR87 was an American liquid-propellant rocket engine used on the first stages of Titan intercontinental ballistic missiles and launch vehicles. Composed of twin motors with separate combustion chambers and turbopump machinery, it is considered a single unit. The LR87 first flew in 1959.

Fastrac was a turbo pump-fed, liquid rocket engine. The engine was designed by NASA as part of the low cost X-34 Reusable Launch Vehicle (RLV) and as part of the Low Cost Booster Technology project. This engine was later known as the MC-1 engine when it was merged into the X-34 project.

The TR-106 or low-cost pintle engine (LCPE) was a developmental rocket engine designed by TRW under the Space Launch Initiative to reduce the cost of launch services and space flight. Operating on LOX/LH2 the engine had a thrust of 2892 kN, or 650,000 pounds, making it one of the most powerful engines ever constructed.

Rocket propellant is the reaction mass of a rocket. This reaction mass is ejected at the highest achievable velocity from a rocket engine to produce thrust. The energy required can either come from the propellants themselves, as with a chemical rocket, or from an external source, as with ion engines.

The BE-3 is a LH2/LOX rocket engine developed by Blue Origin.

The MARC-60, also known as MB-60, MB-XX, and RS-73, is a liquid-fuel cryogenic rocket engine designed as a collaborative effort by Japan's Mitsubishi Heavy Industries and US' Aerojet Rocketdyne. The engine burns cryogenic liquid oxygen and liquid hydrogen in an open expander cycle, driving the turbopumps with waste heat from the main combustion process.