Related Research Articles

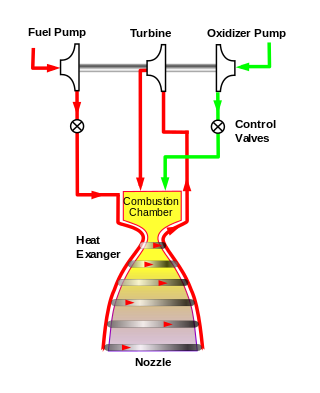

The expander cycle is a power cycle of a bipropellant rocket engine. In this cycle, the fuel is used to cool the engine's combustion chamber, picking up heat and changing phase. The now heated and gaseous fuel then powers the turbine that drives the engine's fuel and oxidizer pumps before being injected into the combustion chamber and burned.

A liquid-propellant rocket or liquid rocket utilizes a rocket engine burning liquid propellants. (Alternate approaches use gaseous or solid propellants.) Liquids are desirable propellants because they have reasonably high density and their combustion products have high specific impulse (Isp). This allows the volume of the propellant tanks to be relatively low.

The J-2, commonly known as Rocketdyne J-2, was a liquid-fuel cryogenic rocket engine used on NASA's Saturn IB and Saturn V launch vehicles. Built in the United States by Rocketdyne, the J-2 burned cryogenic liquid hydrogen (LH2) and liquid oxygen (LOX) propellants, with each engine producing 1,033.1 kN (232,250 lbf) of thrust in vacuum. The engine's preliminary design dates back to recommendations of the 1959 Silverstein Committee. Rocketdyne won approval to develop the J-2 in June 1960 and the first flight, AS-201, occurred on 26 February 1966. The J-2 underwent several minor upgrades over its operational history to improve the engine's performance, with two major upgrade programs, the de Laval nozzle-type J-2S and aerospike-type J-2T, which were cancelled after the conclusion of the Apollo program.

The RL10 is a liquid-fuel cryogenic rocket engine built in the United States by Aerojet Rocketdyne that burns cryogenic liquid hydrogen and liquid oxygen propellants. Modern versions produce up to 110 kN (24,729 lbf) of thrust per engine in vacuum. Three RL10 versions are in production for the Centaur upper stage of the Atlas V and the DCSS of the Delta IV. Three more versions are in development for the Exploration Upper Stage of the Space Launch System and the Centaur V of the Vulcan rocket.

The staged combustion cycle is a power cycle of a bipropellant rocket engine. In the staged combustion cycle, propellant flows through multiple combustion chambers, and is thus combusted in stages. The main advantage relative to other rocket engine power cycles is high fuel efficiency, measured through specific impulse, while its main disadvantage is engineering complexity.

The gas-generator cycle, also called open cycle, is one of the most commonly used power cycles in bipropellant liquid rocket engines.

Vulcain is a family of European first stage rocket engines for Ariane 5 and Ariane 6. Its development began in 1988 and the first flight was completed in 1996. The updated version of the engine, Vulcain 2, was first successfully flown in 2005. Both members of the family use liquid oxygen/liquid hydrogen cryogenic fuel. The new version for Ariane 6 is called Vulcain 2.1.

Vinci is a restartable, cryogenic, liquid-propellant rocket engine that powers the upper stage of Ariane 6. While development began in 1998 for the planned Ariane 5ME upgrade, funding for that programme shifted in 2014 to prioritize the development of Ariane 6, making Vinci the engine for the new launcher.

The YF-73 was China's first successful cryogenic liquid hydrogen fuel and liquid oxygen oxidizer gimballed engine. It was used on the Long March 3 H8 third stage, running on the simple gas generator cycle and with a thrust of 44.15 kilonewtons (9,930 lbf). It had four hinge mounted nozzles that gimbaled each on one axis to supply thrust vector control and was restart capable. It used cavitating flow venturis to regulate propellant flows. The gas generator also incorporated dual heat exchangers that heated hydrogen gas, and supplied helium from separate systems to pressurize the hydrogen and oxygen tanks. The engine was relatively underpowered for its task and the start up and restart procedures were unreliable. Thus, it was quickly replaced by the YF-75.

The YF-75 is a liquid cryogenic rocket engine burning liquid hydrogen and liquid oxygen in a gas generator cycle. It is China's second generation of cryogenic propellant engine, after the YF-73, which it replaced. It is used in a dual engine mount in the H-18 third stage of the Long March 3A, Long March 3B and Long March 3C launch vehicles. Within the mount, each engine can gimbal individually to enable thrust vectoring control. The engine also heats hydrogen and helium to pressurize the stage tanks and can control the mixture ratio to optimize propellant consumption.

The YF-77 is China's first cryogenic rocket engine developed for booster applications. It burns liquid hydrogen fuel and liquid oxygen oxidizer using a gas generator cycle. A pair of these engines powers the LM-5 core stage. Each engine can independently gimbal in two planes. Although the YF-77 is ignited prior to liftoff, the LM-5's four strap-on boosters provide most of the initial thrust in an arrangement similar to the European Vulcain on the Ariane 5 or the Japanese LE-7 on the H-II.

The YF-100 is a Chinese liquid rocket engine burning LOX and kerosene in an oxidizer-rich staged combustion cycle.

The LE-5 liquid rocket engine and its derivative models were developed in Japan to meet the need for an upper stage propulsion system for the H-I and H-II series of launch vehicles. It is a bipropellant design, using LH2 and LOX. Primary design and production work was carried out by Mitsubishi Heavy Industries. In terms of liquid rockets, it is a fairly small engine, both in size and thrust output, being in the 89 kN (20,000 lbf) and the more recent models the 130 kN (30,000 lbf) thrust class. The motor is capable of multiple restarts, due to a spark ignition system as opposed to the single use pyrotechnic or hypergolic igniters commonly used on some contemporary engines. Though rated for up to 16 starts and 40+ minutes of firing time, on the H-II the engine is considered expendable, being used for one flight and jettisoned. It is sometimes started only once for a nine-minute burn, but in missions to GTO the engine is often fired a second time to inject the payload into the higher orbit after a temporary low Earth orbit has been established.

The Armstrong Siddeley, later Bristol SiddeleyGamma was a family of rocket engines used in British rocketry, including the Black Knight and Black Arrow launch vehicles. They burned kerosene fuel and hydrogen peroxide. Their construction was based on a common combustion chamber design, used either singly or in clusters of up to eight.

The RL60 was a planned liquid-fuel cryogenic rocket engine designed in the United States by Pratt & Whitney, burning cryogenic liquid hydrogen and liquid oxygen propellants. The engine runs on an expander cycle, running the turbopumps with waste heat absorbed from the main combustion process. This high-efficiency, waste heat based combustion cycle combined with the high-performance liquid hydrogen fuel enables the engine to reach a very high specific impulse of up to 465 seconds in a vacuum. The engine was planned to be a more capable successor to the Aerojet Rocketdyne RL10, providing improved performance and efficiency while maintaining the installation envelope of the RL10.

A cryogenic rocket engine is a rocket engine that uses a cryogenic fuel and oxidizer; that is, both its fuel and oxidizer are gases which have been liquefied and are stored at very low temperatures. These highly efficient engines were first flown on the US Atlas-Centaur and were one of the main factors of NASA's success in reaching the Moon by the Saturn V rocket.

The RD-0146 (РД-0146) is a liquid-fuel cryogenic rocket engine developed by KBKhA Kosberg in Voronezh, Russia.

The LR87 was an American liquid-propellant rocket engine used on the first stages of Titan intercontinental ballistic missiles and launch vehicles. Composed of twin motors with separate combustion chambers and turbopump machinery, it is considered a single unit and was never flown as a single combustion chamber engine or designed for this. The LR87 first flew in 1959.

Raptor is a family of rocket engines developed and manufactured by SpaceX. It is the third rocket engine in history designed with a full-flow staged combustion (FFSC) fuel cycle, and the first such engine to power a vehicle in flight. The engine is powered by cryogenic liquid methane and liquid oxygen, a mixture known as methalox.

The YF-79 is a liquid cryogenic rocket engine burning liquid hydrogen and liquid oxygen in a closed expander cycle. It is China's fourth generation of upper stage cryogenic propellant engine, after the YF-73, YF-75 and the YF-75D. It can do multiple restarts thanks to an electric spark igniter and a prototype was tested at 60% and 100% thrust levels in December 2021.

References

- 1 2 3 4 Nan, Zhang (2013-09-23). "The Development of LOX/LH2 Engine in China" (PDF). 64rd International Astronautical Congress, Beijing, China. IAC-13-C4.1 (1x18525). International Astronautical Federation: 5. Retrieved 2015-07-08.

- ↑ ZHOU Limin, LIU Zhongxiang (2016). "Development, application, and prospect of expander cycle engine technology". Journal of Rocket Propulsion.

- ↑ "Chang Zheng-5 (Long March-5)". SinoDefence. Archived from the original on 2015-07-03. Retrieved 2015-07-08.

- 1 2 "大面积比喷管高模试验技术研究-手机知网". Wap.cnki.net. Retrieved 2022-04-20.