Related Research Articles

A rocket engine is a reaction engine, producing thrust in accordance with Newton's third law by ejecting reaction mass rearward, usually a high-speed jet of high-temperature gas produced by the combustion of rocket propellants stored inside the rocket. However, non-combusting forms such as cold gas thrusters and nuclear thermal rockets also exist. Rocket vehicles carry their own oxidiser, unlike most combustion engines, so rocket engines can be used in a vacuum, and they can achieve great speed, beyond escape velocity. Vehicles commonly propelled by rocket engines include missiles, artillery shells, ballistic missiles and rockets of any size, from tiny fireworks to man-sized weapons to huge spaceships.

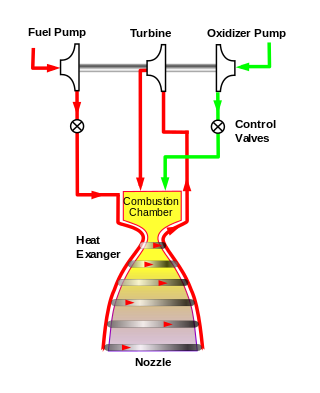

The expander cycle is a power cycle of a bipropellant rocket engine. In this cycle, the fuel is used to cool the engine's combustion chamber, picking up heat and changing phase. The now heated and gaseous fuel then powers the turbine that drives the engine's fuel and oxidizer pumps before being injected into the combustion chamber and burned.

A liquid-propellant rocket or liquid rocket uses a rocket engine burning liquid propellants. (Alternate approaches use gaseous or solid propellants.) Liquids are desirable propellants because they have reasonably high density and their combustion products have high specific impulse (Isp). This allows the volume of the propellant tanks to be relatively low.

Aerozine 50 is a 50:50 mix by weight of hydrazine and unsymmetrical dimethylhydrazine (UDMH), developed in the late 1950s by Aerojet General Corporation as a storable, high-energy, hypergolic fuel for the Titan II ICBM rocket engines. Aerozine continues in wide use as a rocket fuel, typically with dinitrogen tetroxide as the oxidizer, with which it is hypergolic. Aerozine 50 is more stable than hydrazine alone, and has a higher density and boiling point than UDMH alone.

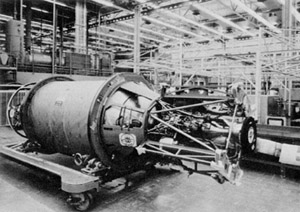

The J-2, commonly known as Rocketdyne J-2, was a liquid-fuel cryogenic rocket engine used on NASA's Saturn IB and Saturn V launch vehicles. Built in the United States by Rocketdyne, the J-2 burned cryogenic liquid hydrogen (LH2) and liquid oxygen (LOX) propellants, with each engine producing 1,033.1 kN (232,250 lbf) of thrust in vacuum. The engine's preliminary design dates back to recommendations of the 1959 Silverstein Committee. Rocketdyne won approval to develop the J-2 in June 1960 and the first flight, AS-201, occurred on 26 February 1966. The J-2 underwent several minor upgrades over its operational history to improve the engine's performance, with two major upgrade programs, the de Laval nozzle-type J-2S and aerospike-type J-2T, which were cancelled after the conclusion of the Apollo program.

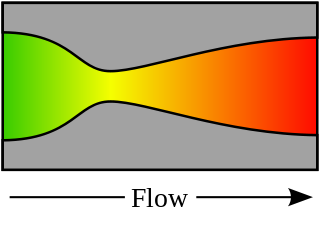

A rocket engine nozzle is a propelling nozzle used in a rocket engine to expand and accelerate combustion products to high supersonic velocities.

The LE-7 and its succeeding upgrade model the LE-7A are staged combustion cycle LH2/LOX liquid rocket engines produced in Japan for the H-II series of launch vehicles. Design and production work was all done domestically in Japan, the first major (main/first-stage) liquid rocket engine with that claim, in a collaborative effort from the National Space Development Agency (NASDA), Aerospace Engineering Laboratory (NAL), Mitsubishi Heavy Industries, and Ishikawajima-Harima. NASDA and NAL have since been integrated into JAXA. However, a large part of the work was contracted to Mitsubishi, with Ishikawajima-Harima providing turbomachinery, and the engine is often referred to as the Mitsubishi LE-7(A).

The Viking rocket engines were members of a series of bipropellant engines for the first and second stages of the Ariane 1 through Ariane 4 commercial launch vehicles, using storable, hypergolic propellants: dinitrogen tetroxide and UH 25, a mixture of 75% UDMH and 25% hydrazine.

The pintle injector is a type of propellant injector for a bipropellant rocket engine. Like any other injector, its purpose is to ensure appropriate flow rate and intermixing of the propellants as they are forcibly injected under high pressure into the combustion chamber, so that an efficient and controlled combustion process can happen.

The LR87 was an American liquid-propellant rocket engine used on the first stages of Titan intercontinental ballistic missiles and launch vehicles. Composed of twin motors with separate combustion chambers and turbopump machinery, it is considered a single unit and was never flown as a single combustion chamber engine or designed for this. The LR87 first flew in 1959.

Fastrac was a turbo pump-fed, liquid rocket engine. The engine was designed by NASA as part of the low cost X-34 Reusable Launch Vehicle (RLV) and as part of the Low Cost Booster Technology project. This engine was later known as the MC-1 engine when it was merged into the X-34 project.

The TR-106 or low-cost pintle engine (LCPE) was a developmental rocket engine designed by TRW under the Space Launch Initiative to reduce the cost of launch services and space flight. Operating on LOX/LH2 the engine had a thrust of 2892 kN, or 650,000 pounds, making it one of the most powerful engines ever constructed.

Rocket propellant is used as reaction mass ejected from a rocket engine to produce thrust. The energy required can either come from the propellants themselves, as with a chemical rocket, or from an external source, as with ion engines.

Executor is a rocket engine developed by ARCA for use on its Haas rocket series and on IAR 111 Excelsior supersonic airplane. Executor uses kerosene and liquid oxygen as propellants in a gas-generator power cycle.

The descent propulsion system or lunar module descent engine (LMDE), internal designation VTR-10, is a variable-throttle hypergolic rocket engine invented by Gerard W. Elverum Jr. and developed by Space Technology Laboratories (TRW) for use in the Apollo Lunar Module descent stage. It used Aerozine 50 fuel and dinitrogen tetroxide oxidizer. This engine used a pintle injector, which paved the way for other engines to use similar designs.

The Delta-P is an American rocket stage, developed by McDonnell Douglas and TRW, first used on November 10, 1972 as the second stage for the Delta 1000 series. It continued to serve as the second stage for subsequent Delta 2000 and Delta 3000 flights for 17 years, with its last usage on February 8, 1988. It is propelled by a single TRW TR-201 rocket engine, fueled by Aerozine 50 and dinitrogen tetroxide, which are hypergolic.

Aestus is a hypergolic liquid rocket engine used on an upper stage of Ariane 5 family rockets for the orbital insertion. It features unique design of 132 coaxial injection elements causing swirl mixing of the MMH propellants with nitrogen tetroxide oxidizer. The pressure-fed engine allows for multiple re-ignitions.

A liquid apogee engine (LAE), or apogee engine, refers to a type of chemical rocket engine typically used as the main engine in a spacecraft.

The Bell Aerosystems Company XLR81 was an American liquid-propellant rocket engine, which was used on the Agena upper stage. It burned UDMH and RFNA fed by a turbopump in a fuel rich gas generator cycle. The turbopump had a single turbine with a gearbox to transmit power to the oxidizer and fuel pumps. The thrust chamber was all-aluminum, and regeneratively cooled by oxidizer flowing through gun-drilled passages in the combustion chamber and throat walls. The nozzle was a titanium radiatively cooled extension. The engine was mounted on a hydraulic actuated gimbal which enabled thrust vectoring to control pitch and yaw. Engine thrust and mixture ratio were controlled by cavitating flow venturis on the gas generator flow circuit. Engine start was achieved by solid propellant start cartridge.

The HWK 109-507 was a liquid-propellant rocket engine developed by Germany during World War II. It was used to propel the Hs 293 anti-ship guided missile.

References

- ↑ US Patent 3,205,656,Elverum Jr., Gerard W.,"Variable thrust bipropellant rocket engine",issued 1963-02-25

- ↑ US Patent 3,699,772,Elverum Jr., Gerard W.,"Liquid propellant rocket engine coaxial injector",issued 1968-01-08

- ↑ REMEMBERING THE GIANTS - Apollo Rocket Propulsion Development. NASA. pp. 73–86.

- ↑ Dressler, Gordon A.; Bauer, J. Martin (July 2000). TRW Pintle Engine Heritage and Performance Characteristics (PDF). 36th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit. Redondo Beach, CA: TRW Inc. doi:10.2514/6.2000-3871. AIAA 2000-3871. Archived (PDF) from the original on 31 March 2022.

- ↑ "TR-201". Encyclopedia Astronautica. Archived from the original on 6 July 2008. Retrieved 4 June 2012.

- ↑ US Patent 3,699,772,Elverum Jr., Gerard W.,"Liquid propellant rocket engine coaxial injector",issued 1968-01-08

- ↑ US Patent 3,205,656,Elverum Jr., Gerard W.,"Variable thrust bipropellant rocket engine",issued 1963-02-25

- ↑ "Delta P". Encyclopedia Astronautica. Archived from the original on 17 June 2012. Retrieved 4 June 2012.