Soyuz is a family of Soviet and later Russian expendable medium-lift launch vehicles developed by the OKB-1 design bureau and manufactured by the Progress Rocket Space Centre in Samara, Russia. It holds the record for the most launches in the history of spaceflight. Soyuz rockets are part of the R-7 rocket family, which evolved from the R-7 Semyorka, an intercontinental ballistic missile.

The Voskhod rocket was a derivative of the Soviet R-7 ICBM designed for the human spaceflight programme but later used for launching Zenit reconnaissance satellites. It was essentially an 8K78/8K78M minus the Blok L stage and spec-wise was a halfway between the two boosters, with the former's older, lower-spec engines and the latter's improved Blok I design. Its first flight was on 16 November 1963 when it successfully launched a Zenit satellite from LC-1/5 at Baikonur. Boosters used in the Voskhod program had a man-rated version of the RD-0107 engine; this version was known as the RD-0108.

The gas-generator cycle, also called open cycle, is one of the most commonly used power cycles in bipropellant liquid rocket engines.

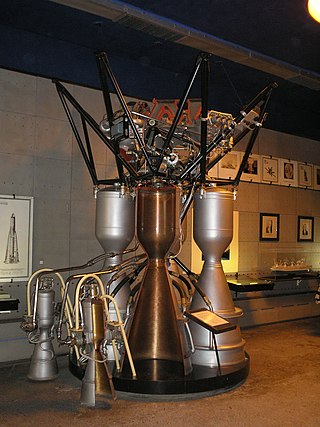

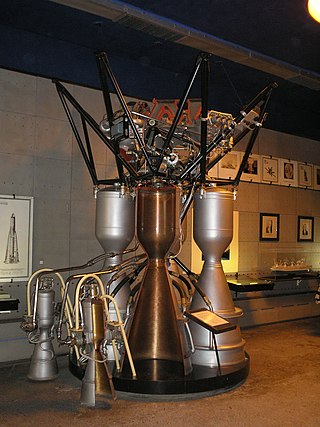

The RD-107 and its sibling, the RD-108, are a type of rocket engine used on the R-7 rocket family. RD-107 engines are used in each booster and the RD-108 is used in the central core. The engines have four main combustion chambers and either two (RD-107) or four (RD-108) vernier chambers.

The Molniya-M was a Soviet Union launch vehicle derived from the R-7 Semyorka Intercontinental ballistic missile (ICBM).

Chemical Automatics Design Bureau (CADB), also KB Khimavtomatika, is a Russian design bureau founded by the NKAP in 1941 and led by Semyon Kosberg until his death in 1965. Its origin dates back to a 1940 Moscow carburetor factory, evacuated to Berdsk in 1941, and then relocated to Voronezh city in 1945, where it now operates. Originally designated OKB-296 and tasked to develop fuel equipment for aviation engines, it was redesignated OKB-154 in 1946.

The RD-0124 is a rocket engine burning liquid oxygen and kerosene in an oxygen-rich staged combustion cycle, developed by the Chemical Automatics Design Bureau in Voronezh. RD-0124 engines are used on the Block I stage used on Soyuz 2.1b and Soyuz 2.1v. A variant of the engine, the RD-0124A, is used on the Angara rocket family's URM-2 upper stage.

The Soyuz was a Soviet expendable carrier rocket designed in the 1960s by OKB-1 and manufactured by State Aviation Plant No. 1 in Kuybyshev, Soviet Union. It was commissioned to launch Soyuz spacecraft as part of the Soviet human spaceflight program, first with 8 uncrewed test flights, followed by the first 19 crewed launches. The original Soyuz also propelled four test flights of the improved Soyuz 7K-T capsule between 1972 and 1974. In total it flew 30 successful missions over 10 years and suffered two failures.

The RD-0146 (РД-0146) is a liquid-fuel cryogenic rocket engine developed by KBKhA Kosberg in Voronezh, Russia.

The S1.5400 was a Soviet single-nozzle liquid-propellant rocket engine burning liquid oxygen and kerosene in an oxidizer-rich staged combustion cycle, being the first rocket engine to use this cycle in the world. It was designed by V. M. Melnikov, an alumnus of Isaev, within Korolev's Bureau, for the Molniya fourth stage, the Block-L. It was also the first Soviet engine designed for start and restart in vacuum and had the highest Isp at the time of its deployment.

The RD-0110R is a rocket engine burning kerosene in liquid oxygen in a gas generator combustion cycle. It has four nozzles that can gimbal up to 45 degrees in a single axis and is used as the vernier thruster on the Soyuz-2-1v first stage. It also has heat exchangers that heat oxygen and helium to pressurize the LOX and RG-1 tanks of the Soyuz-2.1v first stage, respectively. The oxygen is supplied from the same LOX tank in liquid form, while the helium is supplied from separate high pressure bottles.

The RD-0109 is a rocket engine burning liquid oxygen and kerosene in a gas generator combustion cycle. It has single nozzle and is an evolution of the RD-0105. It was the engine used on the Vostok Block-E that launched Yuri Gagarin to orbit.

The RD-0214 (GRAU Index: 8D811) is a rocket vernier engine burning N2O4 and UDMH in a gas generator cycle. It has four nozzles that can each gimbal 45 in plane to provide TVC to the RD-0212 propulsion module of Proton third stage. It is a revised version of the RD-0207.

The RD-0210 (GRAU Index: 8D411K) is also known as the RD-465. It and its twin, the RD-0211, are rocket engines burning N2O4 and UDMH in an oxidizer rich staged combustion cycle. They have single nozzle, possess TVC and are the latest evolution in the RD-0203/4 lineage. They are the engines used on the Proton second stage. The RD-0213 is a fixed nozzle variation that is used on the RD-0212 module of the Proton third stage.

The RD-119 was a liquid rocket engine, burning liquid oxygen and UDMH in the gas-generator cycle. It has a huge expansion ratio on the nozzle and uses a unique propellant combination to achieve an extremely high isp of 352 s for a semi-cryogenic gas-generator engine. It also has a unique steering mechanism. The engine main nozzle is fixed, and the output of the gas generator is fed into four nozzles on the side of the engine. Instead of using gimbaled verniers to supply vector control, the combustion gases are distributed by an electrically driven system that can control the thrust among the nozzles.

The RD-214 (GRAU Index 8D59) was a liquid rocket engine, burning AK-27I (a mixture of 73% nitric acid and 27% N2O4 + iodine passivant and TM-185 (a kerosene and gasoline mix) in the gas generator cycle. As was the case with many V-2 influenced engines, the single turbine was driven by steam generated by catalytic decomposition of hydrogen peroxide. It also had four combustion chambers and vector control was achieved by refractory vanes protruding into the nozzle's exhaust.

Voronezh Mechanical Plant is a Russian engine and heavy machinery manufacturing plant. It is located in the city of Voronezh, in the Voronezh Oblast.

The A.M. Isayev Chemical Engineering Design Bureau, also known as KB KhimMash or just KBKhM, is a Russian rocket engine design and manufacturing company. It is located in the city of Korolyov. It started as the OKB-2 division of the NII-88 research institute, where A.Isaev directed the development of liquid rocket engines for ballistic missile submarines.

The RD-861 is a Soviet liquid propellant rocket engine burning UDMH and nitrogen tetroxide in a gas generator combustion cycle. It has a main combustion chamber, with four vernier nozzles fed by the gas generator output. It can be reignited a single time.

The RD-855 (GRAU Index 8D68M), also known as the RD-68M, is a liquid-fueled rocket engine with four nozzles. As a vernier engine, it provides fine steering adjustments for rockets. It is powered by a combination of N2O4, an oxidizer, and UDMH, a propellant. This combination is hypergolic, meaning the two substances ignite on contact, eliminating the need for an external ignition source.