A monopropellant rocket is a rocket that uses a single chemical as its propellant. Monopropellant rockets are commonly used as small attitude and trajectory control rockets in satellites, rocket upper stages, manned spacecraft, and spaceplanes.

The Apollo Lunar Module, originally designated the Lunar Excursion Module (LEM), was the lunar lander spacecraft that was flown between lunar orbit and the Moon's surface during the United States' Apollo program. It was the first crewed spacecraft to operate exclusively in the airless vacuum of space, and remains the only crewed vehicle to land anywhere beyond Earth.

A rocket engine uses stored rocket propellants as the reaction mass for forming a high-speed propulsive jet of fluid, usually high-temperature gas. Rocket engines are reaction engines, producing thrust by ejecting mass rearward, in accordance with Newton's third law. Most rocket engines use the combustion of reactive chemicals to supply the necessary energy, but non-combusting forms such as cold gas thrusters and nuclear thermal rockets also exist. Vehicles propelled by rocket engines are commonly used by ballistic missiles and rockets. Rocket vehicles carry their own oxidiser, unlike most combustion engines, so rocket engines can be used in a vacuum to propel spacecraft and ballistic missiles.

Big Dumb Booster (BDB) is a general class of launch vehicle based on the premise that it is cheaper to operate large rockets of simple design than it is to operate smaller, more complex ones regardless of the lower payload efficiency. As referred to by the Office of Technology Assessment:

The term Big Dumb Booster has been applied to a wide variety of concepts for low-cost launch vehicles, especially those that would use "low technology" approaches to engines and propellant tanks in the booster stage. As used here, it refers to the criterion of designing launch systems for minimum cost by using simplified subsystems where appropriate.

AS-201, flown February 26, 1966, was the first uncrewed test flight of an entire production Block I Apollo command and service module and the Saturn IB launch vehicle. The spacecraft consisted of the second Block I command module and the first Block I service module. The suborbital flight was a partially successful demonstration of the service propulsion system and the reaction control systems of both modules, and successfully demonstrated the capability of the command module's heat shield to survive re-entry from low Earth orbit.

The Apollo spacecraft was composed of three parts designed to accomplish the American Apollo program's goal of landing astronauts on the Moon by the end of the 1960s and returning them safely to Earth. The expendable (single-use) spacecraft consisted of a combined command and service module (CSM) and an Apollo Lunar Module (LM). Two additional components complemented the spacecraft stack for space vehicle assembly: a spacecraft–LM adapter (SLA) designed to shield the LM from the aerodynamic stress of launch and to connect the CSM to the Saturn launch vehicle and a launch escape system (LES) to carry the crew in the command module safely away from the launch vehicle in the event of a launch emergency.

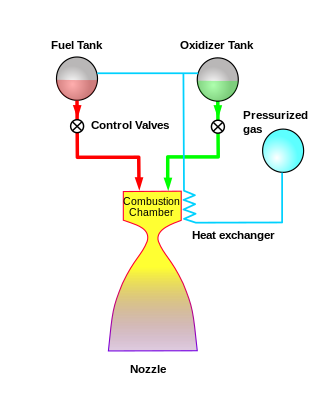

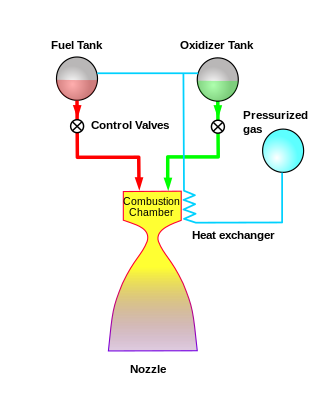

A liquid-propellant rocket or liquid rocket uses a rocket engine burning liquid propellants. (Alternate approaches use gaseous or solid propellants.) Liquids are desirable propellants because they have reasonably high density and their combustion products have high specific impulse (Isp). This allows the volume of the propellant tanks to be relatively low.

A service module is a component of a crewed space capsule containing a variety of support systems used for spacecraft operations. Usually located in the uninhabited area of the spacecraft, the service module serves a storehouse of critical subsystems and supplies for the mission such as electrical systems, environmental control, and propellant tanks. The service module is jettisoned upon the completion of the mission, and usually burns up during atmospheric reentry.

The J-2, commonly known as Rocketdyne J-2, was a liquid-fuel cryogenic rocket engine used on NASA's Saturn IB and Saturn V launch vehicles. Built in the United States by Rocketdyne, the J-2 burned cryogenic liquid hydrogen (LH2) and liquid oxygen (LOX) propellants, with each engine producing 1,033.1 kN (232,250 lbf) of thrust in vacuum. The engine's preliminary design dates back to recommendations of the 1959 Silverstein Committee. Rocketdyne won approval to develop the J-2 in June 1960 and the first flight, AS-201, occurred on 26 February 1966. The J-2 underwent several minor upgrades over its operational history to improve the engine's performance, with two major upgrade programs, the de Laval nozzle-type J-2S and aerospike-type J-2T, which were cancelled after the conclusion of the Apollo program.

The RL10 is a liquid-fuel cryogenic rocket engine built in the United States by Aerojet Rocketdyne that burns cryogenic liquid hydrogen and liquid oxygen propellants. Modern versions produce up to 110 kN (24,729 lbf) of thrust per engine in vacuum. Three RL10 versions are in production for the Centaur upper stage of the Atlas V and the DCSS of the Delta IV. Three more versions are in development for the Exploration Upper Stage of the Space Launch System and the Centaur V of the Vulcan rocket.

The Apollo command and service module (CSM) was one of two principal components of the United States Apollo spacecraft, used for the Apollo program, which landed astronauts on the Moon between 1969 and 1972. The CSM functioned as a mother ship, which carried a crew of three astronauts and the second Apollo spacecraft, the Apollo Lunar Module, to lunar orbit, and brought the astronauts back to Earth. It consisted of two parts: the conical command module, a cabin that housed the crew and carried equipment needed for atmospheric reentry and splashdown; and the cylindrical service module which provided propulsion, electrical power and storage for various consumables required during a mission. An umbilical connection transferred power and consumables between the two modules. Just before reentry of the command module on the return home, the umbilical connection was severed and the service module was cast off and allowed to burn up in the atmosphere.

The pressure-fed engine is a class of rocket engine designs. A separate gas supply, usually helium, pressurizes the propellant tanks to force fuel and oxidizer to the combustion chamber. To maintain adequate flow, the tank pressures must exceed the combustion chamber pressure.

The Altair spacecraft, previously known as the Lunar Surface Access Module or LSAM, was the planned lander spacecraft component of NASA's cancelled Constellation program. Astronauts would have used the spacecraft for landings on the Moon, which was intended to begin around 2019. The Altair spacecraft was planned to be used both for lunar sortie and lunar outpost missions.

Lunar escape systems (LESS) were a series of emergency vehicles designed for never-flown long-duration Apollo missions. Because these missions were more hypothetical than the planned cancelled Apollo missions, the designs were never constructed. This concept was an outgrowth of the Lunar Flying Vehicle by Bell Aerospace.

A gravity turn or zero-lift turn is a maneuver used in launching a spacecraft into, or descending from, an orbit around a celestial body such as a planet or a moon. It is a trajectory optimization that uses gravity to steer the vehicle onto its desired trajectory. It offers two main advantages over a trajectory controlled solely through the vehicle's own thrust. First, the thrust is not used to change the spacecraft's direction, so more of it is used to accelerate the vehicle into orbit. Second, and more importantly, during the initial ascent phase the vehicle can maintain low or even zero angle of attack. This minimizes transverse aerodynamic stress on the launch vehicle, allowing for a lighter launch vehicle.

The pintle injector is a type of propellant injector for a bipropellant rocket engine. Like any other injector, its purpose is to ensure appropriate flow rate and intermixing of the propellants as they are forcibly injected under high pressure into the combustion chamber, so that an efficient and controlled combustion process can happen.

The Orbital Maneuvering System (OMS) is a system of hypergolic liquid-propellant rocket engines used on the Space Shuttle and the Orion MPCV. Designed and manufactured in the United States by Aerojet, the system allowed the orbiter to perform various orbital maneuvers according to requirements of each mission profile: orbital injection after main engine cutoff, orbital corrections during flight, and the final deorbit burn for reentry. From STS-90 onwards the OMS were typically ignited part-way into the Shuttle's ascent for a few minutes to aid acceleration to orbital insertion. Notable exceptions were particularly high-altitude missions such as those supporting the Hubble Space Telescope (STS-31) or those with unusually heavy payloads such as Chandra (STS-93). An OMS dump burn also occurred on STS-51-F, as part of the Abort to Orbit procedure.

The TR-106 or low-cost pintle engine (LCPE) was a developmental rocket engine designed by TRW under the Space Launch Initiative to reduce the cost of launch services and space flight. Operating on LOX/LH2 the engine had a thrust of 2892 kN, or 650,000 pounds, making it one of the most powerful engines ever constructed.

The TR-201 or TR201 is a hypergolic pressure-fed rocket engine used to propel the upper stage of the Delta rocket, referred to as Delta-P, from 1972 to 1988. The rocket engine uses Aerozine 50 as fuel, and N

2O

4 as oxidizer. It was developed in the early 1970s by TRW as a derivative of the lunar module descent engine (LMDE). This engine used a pintle injector first invented by Gerard W. Elverum Jr. and developed by TRW in the late 1950s and received US Patent in 1972. This injector technology and design is also used on SpaceX Merlin engines.

The ascent propulsion system (APS) or lunar module ascent engine (LMAE) is a fixed-thrust hypergolic rocket engine developed by Bell Aerosystems for use in the Apollo Lunar Module ascent stage. It used Aerozine 50 fuel, and N

2O

4 oxidizer. Rocketdyne provided the injector system, at the request of NASA, when Bell could not solve combustion instability problems.