Future of ISO13399

This article may need to be rewritten to comply with Wikipedia's quality standards.(May 2009) |

ISO 13399 (Cutting tool data representation and exchange) is an international technical standard by ISO (the International Organization for Standardization) for the computer-interpretable representation and exchange of industrial product data about cutting tools and toolholders. The objective is to provide a mechanism capable of describing product data regarding cutting tools, independent from any particular system. The nature of this description makes it suitable not only for neutral file exchange (free of proprietary format constraints), but also as a basis for implementing and sharing product databases and archiving, regarding cutting tools.

Typically ISO 13399 can be used to exchange data between computer-aided design (CAD), computer-aided manufacturing (CAM), computer-aided engineering (CAE), tool management software, product data management (PDM/EDM), manufacturing resource planning (MRP) or enterprise resource planning (ERP), and other computer-aided technologies (CAx) and systems.

The usage of the ISO 13399 standard will simplify the exchange of data for cutting tools. Expected results are lower cost for managing the information about tools and a more accurate and efficient usage of manufacturing resources. The ISO 13399 has been developed with contributions from AB Sandvik Coromant, the Royal Institute of Technology in Stockholm, Kennametal Inc, and Ferroday Ltd.

ISO 13399 is developed and maintained by the ISO technical committee TC 29, Small tools, sub-committee WG34. Like other ISO and IEC standards ISO 13399 is copyright by ISO and is not freely available. Other standards developed and maintained by ISO TC29/WG34 are:

ISO 13399 is divided into several parts:

ISO 13399 defines a data model for cutting tool information using the EXPRESS modelling language. Application data according to this data model can be exchanged either by a STEP-File, STEP-XML or via shared database access using SDAI.

The dictionary (reference data library) of ISO 13399 currently uses PLIB (ISO 13584, IEC 61360).

This article may need to be rewritten to comply with Wikipedia's quality standards.(May 2009) |

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common. It may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material, while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the machine tool. CAM is used in many schools alongside CAD to create objects.

Geometric dimensioning and tolerancing (GD&T) is a system for defining and communicating engineering tolerances via a symbolic language on engineering drawings and computer-generated 3D models that describes a physical object's nominal geometry and the permissible variation thereof. GD&T is used to define the nominal geometry of parts and assemblies, the allowable variation in size, form, orientation, and location of individual features, and how features may vary in relation to one another such that a component is considered satisfactory for its intended use. Dimensional specifications define the nominal, as-modeled or as-intended geometry, while tolerance specifications define the allowable physical variation of individual features of a part or assembly.

ISO 10303 is an ISO standard for the computer-interpretable representation and exchange of product manufacturing information. It is an ASCII-based format. Its official title is: Automation systems and integration — Product data representation and exchange. It is known informally as "STEP", which stands for "Standard for the Exchange of Product model data". ISO 10303 can represent 3D objects in Computer-aided design (CAD) and related information.

Computer-aided technologies (CAx) is the use of computer technology to aid in the design, analysis, and manufacture of products.

STEP-file is a widely used data exchange form of STEP. ISO 10303 can represent 3D objects in computer-aided design (CAD) and related information. Due to its ASCII structure, a STEP-file is easy to read, with typically one instance per line. The format of a STEP-file is defined in ISO 10303-21 Clear Text Encoding of the Exchange Structure.

A metadata registry is a central location in an organization where metadata definitions are stored and maintained in a controlled method.

Product and manufacturing information, also abbreviated PMI, conveys non-geometric attributes in 3D computer-aided design (CAD) and Collaborative Product Development systems necessary for manufacturing product components and assemblies. PMI may include geometric dimensions and tolerances, 3D annotation (text) and dimensions, surface finish, and material specifications. PMI is used in conjunction with the 3D model within model-based definition to allow for the elimination of 2D drawings for data set utilization.

JT is an openly-published ISO-standardized 3D CAD data exchange format used for product visualization, collaboration, digital mockups, and other purposes. It was developed by Siemens.

CAD data exchange is a method of drawing data exchange used to translate between different computer-aided design (CAD) authoring systems or between CAD and other downstream CAx systems.

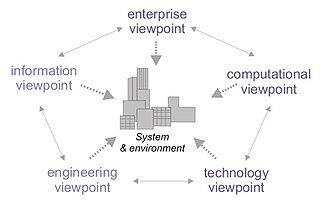

Reference Model of Open Distributed Processing (RM-ODP) is a reference model in computer science, which provides a co-ordinating framework for the standardization of open distributed processing (ODP). It supports distribution, interworking, platform and technology independence, and portability, together with an enterprise architecture framework for the specification of ODP systems.

Software asset management (SAM) is a business practice that involves managing and optimizing the purchase, deployment, maintenance, utilization, and disposal of software applications within an organization. According to ITIL, SAM is defined as “…all of the infrastructure and processes necessary for the effective management, control, and protection of the software assets…throughout all stages of their lifecycle.” Fundamentally intended to be part of an organization's information technology business strategy, the goals of SAM are to reduce information technology (IT) costs and limit business and legal risk related to the ownership and use of software, while maximizing IT responsiveness and end-user productivity. SAM is particularly important for large corporations regarding redistribution of licenses and managing legal risks associated with software ownership and expiration. SAM technologies track license expiration, thus allowing the company to function ethically and within software compliance regulations. This can be important for both eliminating legal costs associated with license agreement violations and as part of a company's reputation management strategy. Both are important forms of risk management and are critical for large corporations' long-term business strategies.

EXPRESS is a standard for generic data modeling language for product data. EXPRESS is formalized in the ISO Standard for the Exchange of Product model STEP, and standardized as ISO 10303-11.

The official title of ISO 13584 is Industrial automation systems and integration - Parts library, with the acronym PLIB. PLIB is developed and maintained by the ISO technical committee TC 184, Technical Industrial automation systems and integration, sub-committee SC4 Industrial data. See also ISO 10303.

STEP-NC is a machine tool control language that extends the ISO 10303 STEP standards with the machining model in ISO 14649, adding geometric dimension and tolerance data for inspection, and the STEP PDM model for integration into the wider enterprise. The combined result has been standardized as ISO 10303-238.

Tool management is needed in metalworking so that the information regarding the tools on hand can be uniformly organized and integrated. The information is stored in a database and is registered and applied using tool management. Tool data management consists of specific data fields, graphics and parameters that are essential in production, as opposed to managing general production equipment.

IEC Common Data Dictionary (abbreviated: IEC CDD) is a metadata registry providing product classification and formalized product descriptions that can be used in the context of smart manufacturing and Industrie 4.0.

MPEG-G is an ISO/IEC standard designed for genomic information representation by the collaboration of the ISO/IEC JTC 1/SC 29/WG 9 (MPEG) and ISO TC 276 "Biotechnology" Work Group 5. The goal of the standard is to provide interoperable solutions for data storage, access, and protection across different possible implementations for data information generated by high-throughput sequencing machines and their subsequent processing and analysis. The standard is composed of different parts, each one addressing a specific aspect, such as compression, metadata association, Application Programming Interfaces (APIs), and a reference software for data decoding. Together with the reference decoder software, commercial and open source implementations started to be available in 2019, covering progressively more of the published parts of the standard.