Related Research Articles

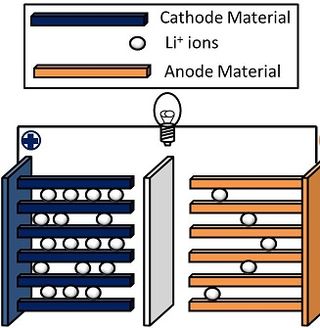

A lithium-ion or Li-ion battery is a type of rechargeable battery that uses the reversible intercalation of Li+ ions into electronically conducting solids to store energy. In comparison with other commercial rechargeable batteries, Li-ion batteries are characterized by higher specific energy, higher energy density, higher energy efficiency, a longer cycle life, and a longer calendar life. Also noteworthy is a dramatic improvement in lithium-ion battery properties after their market introduction in 1991: within the next 30 years, their volumetric energy density increased threefold while their cost dropped tenfold.

Michael Stanley Whittingham is a British-American chemist. He is a professor of chemistry and director of both the Institute for Materials Research and the Materials Science and Engineering program at Binghamton University, State University of New York. He also serves as director of the Northeastern Center for Chemical Energy Storage (NECCES) of the U.S. Department of Energy at Binghamton. He was awarded the Nobel Prize in Chemistry in 2019 alongside Akira Yoshino and John B. Goodenough.

The lithium iron phosphate battery or LFP battery is a type of lithium-ion battery using lithium iron phosphate as the cathode material, and a graphitic carbon electrode with a metallic backing as the anode. Because of their low cost, high safety, low toxicity, long cycle life and other factors, LFP batteries are finding a number of roles in vehicle use, utility-scale stationary applications, and backup power. LFP batteries are cobalt-free. As of September 2022, LFP type battery market share for EVs reached 31%, and of that, 68% was from Tesla and Chinese EV maker BYD production alone. Chinese manufacturers currently hold a near monopoly of LFP battery type production. With patents having started to expire in 2022 and the increased demand for cheaper EV batteries, LFP type production is expected to rise further and surpass lithium nickel manganese cobalt oxides (NMC) type batteries in 2028.

Nanobatteries are fabricated batteries employing technology at the nanoscale, particles that measure less than 100 nanometers or 10−7 meters. These batteries may be nano in size or may use nanotechnology in a macro scale battery. Nanoscale batteries can be combined to function as a macrobattery such as within a nanopore battery.

Lithium iron phosphate or lithium ferro-phosphate (LFP) is an inorganic compound with the formula LiFePO

4. It is a gray, red-grey, brown or black solid that is insoluble in water. The material has attracted attention as a component of lithium iron phosphate batteries, a type of Li-ion battery. This battery chemistry is targeted for use in power tools, electric vehicles, solar energy installations and more recently large grid-scale energy storage.

Nanoball batteries are an experimental type of battery with either the cathode or anode made of nanosized balls that can be composed of various materials such as carbon and lithium iron phosphate. Batteries which use nanotechnology are more capable than regular batteries because of the vastly improved surface area which allows for greater electrical performance, such as fast charging and discharging.

The lithium–air battery (Li–air) is a metal–air electrochemical cell or battery chemistry that uses oxidation of lithium at the anode and reduction of oxygen at the cathode to induce a current flow.

A potassium-ion battery or K-ion battery is a type of battery and analogue to lithium-ion batteries, using potassium ions for charge transfer instead of lithium ions. It was invented by the Iranian/American chemist Ali Eftekhari in 2004.

Sodium-ion batteries (NIBs, SIBs, or Na-ion batteries) are several types of rechargeable batteries, which use sodium ions (Na+) as its charge carriers. In some cases, its working principle and cell construction are similar to those of lithium-ion battery (LIB) types, but it replaces lithium with sodium as the intercalating ion. Sodium belongs to the same group in the periodic table as lithium and thus has similar chemical properties. Although, in some cases (such as aqueous Na-ion batteries) they are quite different from Li-ion batteries.

Aluminium-ion batteries are a class of rechargeable battery in which aluminium ions serve as charge carriers. Aluminium can exchange three electrons per ion. This means that insertion of one Al3+ is equivalent to three Li+ ions. Thus, since the ionic radii of Al3+ (0.54 Å) and Li+ (0.76 Å) are similar, significantly higher numbers of electrons and Al3+ ions can be accepted by cathodes with little damage. Al has 50 times (23.5 megawatt-hours m-3) the energy density of Li and is even higher than coal.

Research in lithium-ion batteries has produced many proposed refinements of lithium-ion batteries. Areas of research interest have focused on improving energy density, safety, rate capability, cycle durability, flexibility, and cost.

NASICON is an acronym for sodium (Na) super ionic conductor, which usually refers to a family of solids with the chemical formula Na1+xZr2SixP3−xO12, 0 < x < 3. In a broader sense, it is also used for similar compounds where Na, Zr and/or Si are replaced by isovalent elements. NASICON compounds have high ionic conductivities, on the order of 10−3 S/cm, which rival those of liquid electrolytes. They are caused by hopping of Na ions among interstitial sites of the NASICON crystal lattice.

Lithium hybrid organic batteries are an energy storage device that combines lithium with an organic polymer. For example, polyaniline vanadium (V) oxide (PAni/V2O5) can be incorporated into the nitroxide-polymer lithium iron phosphate battery, PTMA/LiFePO4. Together, they improve the lithium ion intercalation capacity, cycle life, electrochemical performances, and conductivity of batteries.

Vanadium phosphates are inorganic compounds with the formula VOxPO4 as well related hydrates with the formula VOxPO4(H2O)n. Some of these compounds are used commercially as catalysts for oxidation reactions.

Magnesium batteries are batteries that utilize magnesium cations as charge carriers and possibly in the anode in electrochemical cells. Both non-rechargeable primary cell and rechargeable secondary cell chemistries have been investigated. Magnesium primary cell batteries have been commercialised and have found use as reserve and general use batteries.

A semi-solid flow battery is a type of flow battery using solid battery active materials or involving solid species in the energy carrying fluid. A research team in MIT proposed this concept using lithium-ion battery materials. In such a system, both positive (cathode) and negative electrode (anode) consist of active material particles with carbon black suspended in liquid electrolyte. Active material suspensions are stored in two energy storage tanks. The suspensions are pumped into the electrochemical reaction cell when charging and discharging. This design takes advantage of both the designing flexibility of flow batteries and the high energy density active materials of lithium-ion batteries.

Lithium nickel manganese cobalt oxides (abbreviated NMC, Li-NMC, LNMC, or NCM) are mixed metal oxides of lithium, nickel, manganese and cobalt with the general formula LiNixMnyCo1-x-yO2. These materials are commonly used in lithium-ion batteries for mobile devices and electric vehicles, acting as the positively charged cathode.

Lithium aluminium germanium phosphate, typically known with the acronyms LAGP or LAGPO, is an inorganic ceramic solid material whose general formula is Li

1+xAl

xGe

2-x(PO

4)

3. LAGP belongs to the NASICON family of solid conductors and has been applied as a solid electrolyte in all-solid-state lithium-ion batteries. Typical values of ionic conductivity in LAGP at room temperature are in the range of 10–5 - 10–4 S/cm, even if the actual value of conductivity is strongly affected by stoichiometry, microstructure, and synthesis conditions. Compared to lithium aluminium titanium phosphate (LATP), which is another phosphate-based lithium solid conductor, the absence of titanium in LAGP improves its stability towards lithium metal. In addition, phosphate-based solid electrolytes have superior stability against moisture and oxygen compared to sulfide-based electrolytes like Li

10GeP

2S

12 (LGPS) and can be handled safely in air, thus simplifying the manufacture process. Since the best performances are encountered when the stoichiometric value of x is 0.5, the acronym LAGP usually indicates the particular composition of Li

1.5Al

0.5Ge

1.5(PO

4)

3, which is also the typically used material in battery applications.

This is a history of the lithium-ion battery.

Karim Zaghib is an Algerian-Canadian electrochemist and materials scientist known for his contributions to the field of energy storage and conversion. He is currently Professor of Chemical and Materials Engineering at Concordia University. As former director of research at Hydro-Québec, he helped to make it the world’s first company to use lithium iron phosphate in cathodes, and to develop natural graphite and nanotitanate anodes.

References

- ↑ Saıdi, M.Y.; Barker, J.; Huang, H.; Swoyer, J.L.; Adamson, G. (1 June 2003), "Performance characteristics of lithium vanadium phosphate as a cathode material for lithium-ion batteries", Journal of Power Sources, 119–121: 266–272, Bibcode:2003JPS...119..266S, doi:10.1016/S0378-7753(03)00245-3 Selected papers presented at the 11th International Meeting on Lithium Batteries

- ↑ Huang, H.; Yin, S.-C.; Kerr, T.; Taylor, N.; Nazar, L.F. (2002), "Nanostructured Composites: A High Capacity, Fast Rate Li3V2(PO4)3/Carbon Cathode for Rechargeable Lithium Batteries", Adv. Mater., 14 (21): 1525–1528, Bibcode:2002AdM....14.1525H, doi: 10.1002/1521-4095(20021104)14:21<1525::AID-ADMA1525>3.0.CO;2-3

- ↑ Zhu, X.J.; Liu, Y.X.; Geng, L.M.; Chen, L.B. (1 October 2008), "Synthesis and performance of lithium vanadium phosphate as cathode materials for lithium ion batteries by a sol–gel method", Journal of Power Sources, 184 (2): 578–582, Bibcode:2008JPS...184..578Z, doi:10.1016/j.jpowsour.2008.01.007

- ↑ Stanley Whittingham, M.; Song, Yanning; Lutta, Samuel; Zavalija, Peter Y.; Chernovaa, Natasha A. (2005), "Some transition metal (oxy)phosphates and vanadium oxides for lithium batteries", J. Mater. Chem., 15 (33): 3362–3379, doi:10.1039/B501961C

- ↑ Chen, Zehua; Chen, Qiyuan; Chen, Liquan; Zhang, Ruibo; Zhou, Hui; Chernova, Natasha A.; Whittingham, M. Stanley (2013). "Electrochemical Behavior of Nanostructured ε-VOPO4 over Two Redox Plateaus". Journal of the Electrochemical Society. 160 (10): A1777. doi: 10.1149/2.064310jes .