A rifled breech loader (RBL) is an artillery piece which, unlike the smoothbore cannon and rifled muzzle loader (RML) which preceded it, has rifling in the barrel and is loaded from the breech at the rear of the gun.

This article explains terms used for the British Armed Forces' ordnance and also ammunition. The terms may have slightly different meanings in the military of other countries.

The Type 11 70 mm infantry mortar, was a muzzle-loading, rifled bore infantry mortar used by the Japanese. The Type 11 designation was given to this gun as it was accepted in the 11th year of Emperor Taishō's reign (1922). It was first used in 1922 and was the first mortar to be introduced by the Imperial Japanese Army. The mortar was later replaced by the Type 92 battalion gun.

The Armstrong RBL 7-inch gun, also known as the 110-pounder, was an early attempt to use William Armstrong's new and innovative rifled breechloading mechanism for heavy rifled guns.

A muzzle-loading rifle is a muzzle-loaded small arm or artillery piece that has a rifled barrel rather than a smoothbore. The term "rifled muzzle loader" typically is used to describe a type of artillery piece, although it is technically accurate for small arms as well. A shoulder arm is typically just called a "rifle", as almost all small arms were rifled by the time breechloading became prevalent. Muzzle and breechloading artillery served together for several decades, making a clear distinction more important. In the case of artillery, the abbreviation "RML" is often prefixed to the guns designation; a Rifled breech loader would be "RBL", or often just "BL", since smoothbore breechloading artillery is almost nonexistent. A muzzle loading weapon is loaded through the muzzle, or front of the barrel. This is the opposite of a breech-loading weapon or rifled breechloader (RBL), which is loaded from the breech-end of the barrel. The rifling grooves cut on the inside of the barrel cause the projectile to spin rapidly in flight, giving it greater stability and hence range and accuracy than smoothbore guns. Hand held rifles were well-developed by the 1740s. A popularly recognizable form of the "muzzleloader" is the Kentucky Rifle, which was actually developed in Pennsylvania. The American Longrifle evolved from the German "Jäger" rifle.

The Ordnance RML 2.5-inch mountain gun was a British rifled muzzle-loading mountain gun of the late 19th century designed to be broken down into four loads for carrying by man or mule. It was primarily used by the Indian Army.

The Armstrong Breech Loading 12 pounder 8 cwt, later known as RBL 12 pounder 8 cwt, was an early modern 3-inch rifled breech-loading field gun of 1859.

The BL 13.5 inch naval gun Mk I was Britain's first successful large breechloading naval gun, initially designed in the early 1880s and eventually deployed in the late 1880s. Mks I - IV were all of 30 calibres length and of similar construction and performance.

The RML 10-inch guns Mk I – Mk II were large rifled muzzle-loading guns designed for British battleships and monitors in the 1860s to 1880s. They were also fitted to the Bouncer and Ant-class flat-iron gunboats. They were also used for fixed coastal defences around the United Kingdom and around the British Empire until the early years of the 20th Century.

The RML 9-inch guns Mark I – Mark VI were large rifled muzzle-loading guns of the 1860s used as primary armament on smaller British ironclad battleships and secondary armament on larger battleships, and also ashore for coast defence.

A Blakely rifle is one of a series of rifled muzzle-loading cannon designed by British army officer Captain Theophilus Alexander Blakely. They were widely sold outside of the British army, and were best known for their use by the Confederate States of America during the American Civil War.

RML 16-inch 80-ton guns were large rifled muzzle-loading guns intended to give the largest British battleships parity with the large guns being mounted by Italian and French ships in the Mediterranean Sea in the 1870s.

The RML 12-inch 25-ton guns were large rifled muzzle-loading guns of mid-late 1800s used as primary armament on British ironclad turret battleships and coastal monitors, and also ashore for coast defence. They were the shorter and less powerful of the two 12-inch (305-mm) British RML guns, the other being the 35-ton gun.

The 68-pounder cannon was an artillery piece designed and used by the British Armed Forces in the mid-19th century. The cannon was a smoothbore muzzle-loading gun manufactured in several weights, the most common being 95 long cwt (4,800 kg), and fired projectiles of 68 lb (31 kg). Colonel William Dundas designed the 112 cwt version in 1841 and it was cast the following year. The most common variant, weighing 95 cwt, dates from 1846. It entered service with the Royal Artillery and the Royal Navy and saw active service with both arms during the Crimean War. Over 2,000 were made and it gained a reputation as the finest smoothbore cannon ever made.

The RML 7-inch guns were various designs of medium-sized rifled muzzle-loading guns used to arm small to medium-sized British warships in the late 19th century, and some were used ashore for coast defence.

The British RML 8-inch 9-ton guns Mark I – Mark III were medium rifled muzzle-loading guns used to arm smaller ironclad warships and coast defence batteries in the later 19th century.

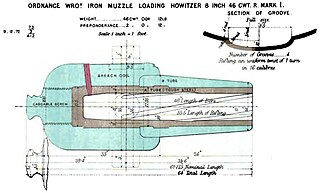

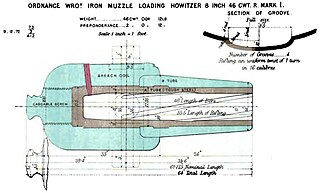

The RML 8-inch howitzer was a British Rifled, Muzzle Loading (RML) Howitzer manufactured in England in the 19th century, which fired a projectile weighing approximately 180 pounds (82 kg). It was used in siege batteries and in fortifications.

The 3-inch Ordnance rifle, Model 1861 was a wrought iron muzzle-loading rifled cannon that was adopted by the United States Army in 1861 and widely used in field artillery units during the American Civil War. It fired a 9.5 lb (4.3 kg) projectile to a distance of 1,830 yd (1,670 m) at an elevation of 5°. The 3-inch rifle was not as effective in firing canister shot as the heavier 12-pounder Napoleon, but it proved to be highly accurate at longer ranges when firing shell or shrapnel. There was only one reported case of a 3-inch Ordnance rifle bursting in action. This was in stark contrast to the similarly-sized cast iron 10-pounder Parrott rifles which occasionally burst without warning, inflicting injury on the gun crews. The Confederate States of America lacked the technology to manufacture successful copies of the 3-inch Ordnance rifle. However, the Confederate States Army respected the weapons and employed those captured from Federal forces.

The RML 25-pounder gun was a British rifled muzzle-loading light siege gun and gun of position designed in 1871. It was intended to be an intermediate gun between the 16-pounder and 40-pounder Rifled Muzzle Loading guns. It was part of a series of guns designed after the British military reverted to rifled muzzle-loading artillery until a more satisfactory breech-loading system than that of the Armstrong guns was developed.

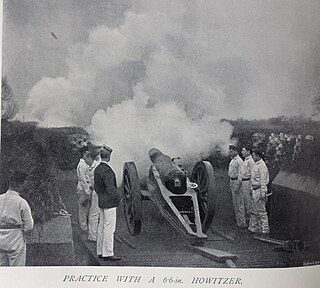

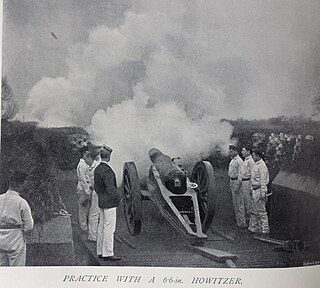

The RML 6.6 inch howitzer was a British Rifled, Muzzle Loading (RML) Howitzer manufactured in England in the 19th century, which fired a projectile weighing approximately 100 pounds (45 kg). It was used in siege batteries and in fortifications.