Pottery is the process and the products of forming vessels and other objects with clay and other raw materials, which are fired at high temperatures to give them a hard and durable form. The place where such wares are made by a potter is also called a pottery. The definition of pottery, used by the ASTM International, is "all fired ceramic wares that contain clay when formed, except technical, structural, and refractory products". End applications include tableware, decorative ware, sanitaryware, and in technology and industry such as electrical insulators and laboratory ware. In art history and archaeology, especially of ancient and prehistoric periods, pottery often means vessels only, and sculpted figurines of the same material are called terracottas.

Delftware or Delft pottery, also known as Delft Blue or as delf, is a general term now used for Dutch tin-glazed earthenware, a form of faience. Most of it is blue and white pottery, and the city of Delft in the Netherlands was the major centre of production, but the term covers wares with other colours, and made elsewhere. It is also used for similar pottery, English delftware.

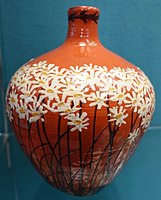

Earthenware is glazed or unglazed nonvitreous pottery that has normally been fired below 1,200 °C (2,190 °F). Basic earthenware, often called terracotta, absorbs liquids such as water. However, earthenware can be made impervious to liquids by coating it with a ceramic glaze, and is used for the great majority of modern domestic earthenware. The main other important types of pottery are porcelain, bone china, and stoneware, all fired at high enough temperatures to vitrify. End applications include tableware and decorative ware such as figurines.

Faience or faïence is the general English language term for fine tin-glazed pottery. The invention of a white pottery glaze suitable for painted decoration, by the addition of an oxide of tin to the slip of a lead glaze, was a major advance in the history of pottery. The invention seems to have been made in Iran or the Middle East before the ninth century. A kiln capable of producing temperatures exceeding 1,000 °C (1,830 °F) was required to achieve this result, the result of millennia of refined pottery-making traditions. The term is now used for a wide variety of pottery from several parts of the world, including many types of European painted wares, often produced as cheaper versions of porcelain styles.

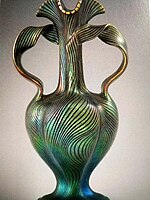

Stoneware is a broad term for pottery fired at a relatively high temperature. A modern definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. End applications include tableware, decorative ware such as vases.

Pottery and porcelain, is one of the oldest Japanese crafts and art forms, dating back to the Neolithic period. Kilns have produced earthenware, pottery, stoneware, glazed pottery, glazed stoneware, porcelain, and blue-and-white ware. Japan has an exceptionally long and successful history of ceramic production. Earthenwares were made as early as the Jōmon period, giving Japan one of the oldest ceramic traditions in the world. Japan is further distinguished by the unusual esteem that ceramics holds within its artistic tradition, owing to the enduring popularity of the tea ceremony.

Salt-glaze or salt glaze pottery is pottery, usually stoneware, with a glaze of glossy, translucent and slightly orange-peel-like texture which was formed by throwing common salt into the kiln during the higher temperature part of the firing process. Sodium from the salt reacts with silica in the clay body to form a glassy coating of sodium silicate. The glaze may be colourless or may be coloured various shades of brown, blue, or purple.

Creamware is a cream-coloured refined earthenware with a lead glaze over a pale body, known in France as faïence fine, in the Netherlands as Engels porselein, and in Italy as terraglia inglese. It was created about 1750 by the potters of Staffordshire, England, who refined the materials and techniques of salt-glazed earthenware towards a finer, thinner, whiter body with a brilliant glassy lead glaze, which proved so ideal for domestic ware that it supplanted white salt-glaze wares by about 1780. It was popular until the 1840s.

Korean ceramic history begins with the oldest earthenware from around 8000 BC. Throughout the history, the Korean peninsula has been home to lively, innovative, and sophisticated art making. Long periods of stability have allowed for the establishment of spiritual traditions, and artisan technologies specific to the region. Korean ceramics in Neolithic period have a unique geometric patterns of sunshine, or it is decorated with twists. In Southern part of Korea, Mumun pottery were popular. Mumun togi used specific minerals to make colors of red and black. Korean pottery developed a distinct style of its own, with its own shapes, such as the moon jar or Buncheong sagi which is a new form between earthenware and porcelain, white clay inlay celadon of Goryeo, and later styles like minimalism that represents Korean Joseon philosophers' idea. Many talented Korean potters were captured and brought to Japan during the invasions of Korea, where they heavily contributed to advancing Japanese pottery. Arita ware, founded by Yi Sam-pyeong opened a new era of porcelain in Japan. Another Japanese representative porcelain, Satsuma ware was also founded by Dang-gil Shim and Pyeong-ui Park. 14th generation of Su-kwan Shim have been using the same name to his grandfather and father to honor they are originally Korean, 14th Su-kwan Shim is honorable citizen of Namwon, Korea.

"Blue and white pottery" covers a wide range of white pottery and porcelain decorated under the glaze with a blue pigment, generally cobalt oxide. The decoration is commonly applied by hand, originally by brush painting, but nowadays by stencilling or by transfer-printing, though other methods of application have also been used. The cobalt pigment is one of the very few that can withstand the highest firing temperatures that are required, in particular for porcelain, which partly accounts for its long-lasting popularity. Historically, many other colours required overglaze decoration and then a second firing at a lower temperature to fix that.

Wedgwood is an English fine china, porcelain and luxury accessories manufacturer that was founded on 1 May 1759 by the potter and entrepreneur Josiah Wedgwood and was first incorporated in 1895 as Josiah Wedgwood and Sons Ltd. It was rapidly successful and was soon one of the largest manufacturers of Staffordshire pottery, "a firm that has done more to spread the knowledge and enhance the reputation of British ceramic art than any other manufacturer", exporting across Europe as far as Russia, and to the Americas. It was especially successful at producing fine earthenware and stoneware that were accepted as equivalent in quality to porcelain but were considerably cheaper.

Royal Doulton is an English ceramic and home accessories manufacturer that was founded in 1815. Operating originally in Vauxhall, London, and later moving to Lambeth, in 1882 it opened a factory in Burslem, Stoke-on-Trent, in the centre of English pottery. From the start, the backbone of the business was a wide range of utilitarian wares, mostly stonewares, including storage jars, tankards and the like, and later extending to drain pipes, lavatories, water filters, electrical porcelain and other technical ceramics. From 1853 to 1901, its wares were marked Doulton & Co., then from 1901, when a royal warrant was given, Royal Doulton.

Chinese ceramics show a continuous development since pre-dynastic times and are one of the most significant forms of Chinese art and ceramics globally. The first pottery was made during the Palaeolithic era. Chinese ceramics range from construction materials such as bricks and tiles, to hand-built pottery vessels fired in bonfires or kilns, to the sophisticated Chinese porcelain wares made for the imperial court and for export. Porcelain was a Chinese invention and is so identified with China that it is still called "china" in everyday English usage.

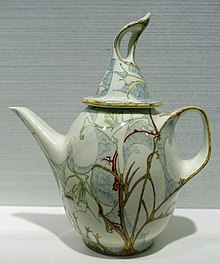

Mintons was a major company in Staffordshire pottery, "Europe's leading ceramic factory during the Victorian era", an independent business from 1793 to 1968. It was a leader in ceramic design, working in a number of different ceramic bodies, decorative techniques, and "a glorious pot-pourri of styles - Rococo shapes with Oriental motifs, Classical shapes with Medieval designs and Art Nouveau borders were among the many wonderful concoctions". As well as pottery vessels and sculptures, the firm was a leading manufacturer of tiles and other architectural ceramics, producing work for both the Houses of Parliament and United States Capitol.

Tin-glazed pottery is earthenware covered in lead glaze with added tin oxide which is white, shiny and opaque ; usually this provides a background for brightly painted decoration. It has been important in Islamic and European pottery, but very little used in East Asia. The pottery body is usually made of red or buff-colored earthenware and the white glaze imitated Chinese porcelain. The decoration on tin-glazed pottery is usually applied to the unfired glaze surface by brush with metallic oxides, commonly cobalt oxide, copper oxide, iron oxide, manganese dioxide and antimony oxide. The makers of Italian tin-glazed pottery from the late Renaissance blended oxides to produce detailed and realistic polychrome paintings.

Gzhel is a Russian style of blue and white ceramics which takes its name from the village of Gzhel and surrounding area, where it has been produced since 1802.

The Fulham Pottery was founded in Fulham, London, by John Dwight in 1672, at the junction of New King's Road and Burlington Road, Fulham, not far from Putney Bridge. Dwight is the earliest clearly documented maker of stoneware in England, although immigrant Dutch or German potters were probably active several decades before. By 1690 there was a rival stoneware operation in Fulham, run by the Dutch Elers brothers, who after a few years went off to become important early figures in transforming the Staffordshire pottery industry.

China painting, or porcelain painting, is the decoration of glazed porcelain objects such as plates, bowls, vases or statues. The body of the object may be hard-paste porcelain, developed in China in the 7th or 8th century, or soft-paste porcelain, developed in 18th-century Europe. The broader term ceramic painting includes painted decoration on lead-glazed earthenware such as creamware or tin-glazed pottery such as maiolica or faience.

Ceramic art is art made from ceramic materials, including clay. It may take varied forms, including artistic pottery, including tableware, tiles, figurines and other sculpture. As one of the plastic arts, ceramic art is a visual art. While some ceramics are considered fine art, such as pottery or sculpture, most are considered to be decorative, industrial or applied art objects. Ceramic art can be created by one person or by a group, in a pottery or a ceramic factory with a group designing and manufacturing the artware.

American art pottery refers to aesthetically distinctive hand-made ceramics in earthenware and stoneware from the period 1870-1950s. Ranging from tall vases to tiles, the work features original designs, simplified shapes, and experimental glazes and painting techniques. Stylistically, most of this work is affiliated with the modernizing Arts and Crafts (1880-1910), Art Nouveau (1890–1910), or Art Deco (1920s) movements, and also European art pottery.

![Haviland & Co. barbotine jardiniere with Barbizon School-style landscape by Emile-Justin Merlot [fr], c. 1880. Flat-sided shapes made the barbotine painting easier. Jardiniere with landscape MET DP704402 (cropped).jpg](http://upload.wikimedia.org/wikipedia/commons/thumb/c/ca/Jardini%C3%A8re_with_landscape_MET_DP704402_%28cropped%29.jpg/220px-Jardini%C3%A8re_with_landscape_MET_DP704402_%28cropped%29.jpg)