A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant.

A radiator is a heat exchanger used to transfer thermal energy from one medium to another for the purpose of cooling and heating. The majority of radiators are constructed to function in cars, buildings, and electronics.

Cupronickel or copper-nickel (CuNi) is an alloy of copper with nickel, usually along with small quantities of other elements added for strength, such as iron and manganese. The copper content typically varies from 60 to 90 percent.

An intercooler is a heat exchanger used to cool a gas after compression. Often found in turbocharged engines, intercoolers are also used in air compressors, air conditioners, refrigeration and gas turbines.

Brazing is a metal-joining process in which two or more metal items are joined by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal.

In metallurgy, a flux is a chemical cleaning agent, flowing agent, or purifying agent. Fluxes may have more than one function at a time. They are used in both extractive metallurgy and metal joining.

Water cooling is a method of heat removal from components and industrial equipment. Evaporative cooling using water is often more efficient than air cooling. Water is inexpensive and non-toxic; however, it can contain impurities and cause corrosion.

Aluminium–silicon alloys or Silumin is a general name for a group of lightweight, high-strength aluminium alloys based on an aluminum–silicon system (AlSi) that consist predominantly of aluminum - with silicon as the quantitatively most important alloying element. Pure AlSi alloys cannot be hardened, the commonly used alloys AlSiCu and AlSiMg can be hardened. The hardening mechanism corresponds to that of AlCu and AlMgSi. The rarely used wrought alloys in the 4000 series and the predominantly used cast alloys are standardised in the 40000 series.

Induction heating is the process of heating electrically conductive materials, namely metals or semi-conductors, by electromagnetic induction, through heat transfer passing through an inductor that creates an electromagnetic field within the coil to heat up and possibly melt steel, copper, brass, graphite, gold, silver, aluminum, or carbide.

Internal combustion engine cooling uses either air or liquid to remove the waste heat from an internal combustion engine. For small or special purpose engines, cooling using air from the atmosphere makes for a lightweight and relatively simple system. Watercraft can use water directly from the surrounding environment to cool their engines. For water-cooled engines on aircraft and surface vehicles, waste heat is transferred from a closed loop of water pumped through the engine to the surrounding atmosphere by a radiator.

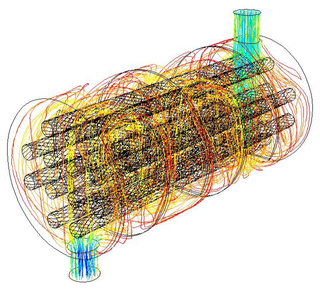

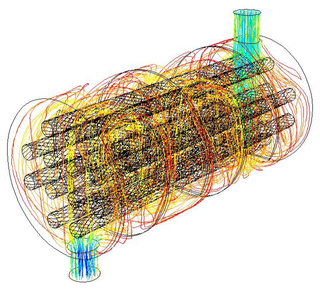

A shell-and-tube heat exchanger is a class of heat exchanger designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this type of heat exchanger consists of a shell with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed of several types of tubes: plain, longitudinally finned, etc.

A surface condenser is a water-cooled shell and tube heat exchanger installed to condense exhaust steam from a steam turbine in thermal power stations. These condensers are heat exchangers which convert steam from its gaseous to its liquid state at a pressure below atmospheric pressure. Where cooling water is in short supply, an air-cooled condenser is often used. An air-cooled condenser is however, significantly more expensive and cannot achieve as low a steam turbine exhaust pressure as a water-cooled surface condenser.

Radiators are heat exchangers used for cooling internal combustion engines, mainly in automobiles but also in piston-engined aircraft, railway locomotives, motorcycles, stationary generating plants or any similar use of such an engine.

Soldering is a process of joining two metal surfaces together using a filler metal called solder. The soldering process involves heating the surfaces to be joined and melting the solder, which is then allowed to cool and solidify, creating a strong and durable joint.

Copper tubing is most often used for heating systems and as a refrigerant line in HVAC systems. Copper tubing is slowly being replaced by PEX tubing in hot and cold water applications. There are two basic types of copper tubing, soft copper and rigid copper. Copper tubing is joined using flare connection, compression connection, pressed connection, or solder. Copper offers a high level of corrosion resistance but is becoming very costly.

Materials for use in vacuum are materials that show very low rates of outgassing in vacuum and, where applicable, are tolerant to bake-out temperatures. The requirements grow increasingly stringent with the desired degree of vacuum to be achieved in the vacuum chamber. The materials can produce gas by several mechanisms. Molecules of gases and water can be adsorbed on the material surface. Materials may sublimate in vacuum. Or the gases can be released from porous materials or from cracks and crevices. Traces of lubricants, residues from machining, can be present on the surfaces. A specific risk is outgassing of solvents absorbed in plastics after cleaning.

Copper has earned a respected place in the related fields of architecture, building construction, and interior design. From cathedrals to castles and from homes to offices, copper is used for a variety of architectural elements, including roofs, flashings, gutters, downspouts, domes, spires, vaults, wall cladding, and building expansion joints.

Heat exchangers are devices that transfer heat to achieve desired heating or cooling. An important design aspect of heat exchanger technology is the selection of appropriate materials to conduct and transfer heat fast and efficiently.

Internally grooved copper tubes, also known as "microfin tubes", are a small diameter coil technology for modern air conditioning and refrigeration systems. Grooved coils facilitate more efficient heat transfer than smooth coils. Small diameter coils have better rates of heat transfer than conventionally-sized condenser and evaporator coils with round copper tubes and aluminum or copper fin that have been the standard in the HVAC industry for many years. Small diameter coils can withstand the higher pressures required by the new generation of environmentally friendlier refrigerants. They have lower material costs because they require less refrigerant, fin, and coil materials. They enable the design of smaller and lighter high-efficiency air conditioners and refrigerators because the evaporator and condenser coils are smaller and lighter.

Aluminium alloys are often used due to their high strength-to-weight ratio, corrosion resistance, low cost, high thermal and electrical conductivity. There are a variety of techniques to join aluminium including mechanical fasteners, welding, adhesive bonding, brazing, soldering and friction stir welding (FSW), etc. Various techniques are used based on the cost and strength required for the joint. In addition, process combinations can be performed to provide means for difficult-to-join assemblies and to reduce certain process limitations.