Pottery is the process and the products of forming vessels and other objects with clay and other raw materials, which are fired at high temperatures to give them a hard and durable form. The place where such wares are made by a potter is also called a pottery. The definition of pottery, used by the ASTM International, is "all fired ceramic wares that contain clay when formed, except technical, structural, and refractory products". End applications include tableware, decorative ware, sanitaryware, and in technology and industry such as electrical insulators and laboratory ware. In art history and archaeology, especially of ancient and prehistoric periods, pottery often means vessels only, and sculpted figurines of the same material are called terracottas.

Stoneware is a broad term for pottery fired at a relatively high temperature. A modern definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. End applications include tableware, decorative ware such as vases.

Pottery and porcelain, is one of the oldest Japanese crafts and art forms, dating back to the Neolithic period. Kilns have produced earthenware, pottery, stoneware, glazed pottery, glazed stoneware, porcelain, and blue-and-white ware. Japan has an exceptionally long and successful history of ceramic production. Earthenwares were made as early as the Jōmon period, giving Japan one of the oldest ceramic traditions in the world. Japan is further distinguished by the unusual esteem that ceramics hold within its artistic tradition, owing to the enduring popularity of the tea ceremony.

Celadon is a term for pottery denoting both wares glazed in the jade green celadon color, also known as greenware or "green ware", and a type of transparent glaze, often with small cracks, that was first used on greenware, but later used on other porcelains. Celadon originated in China, though the term is purely European, and notable kilns such as the Longquan kiln in Zhejiang province are renowned for their celadon glazes. Celadon production later spread to other parts of East Asia, such as Japan and Korea as well as Southeast Asian countries, such as Thailand. Eventually, European potteries produced some pieces, but it was never a major element there. Finer pieces are in porcelain, but both the color and the glaze can be produced in stoneware and earthenware. Most of the earlier Longquan celadon is on the border of stoneware and porcelain, meeting the Chinese but not the European definitions of porcelain.

Terra sigillata is a term with at least three distinct meanings: as a description of medieval medicinal earth; in archaeology, as a general term for some of the fine red Ancient Roman pottery with glossy surface slips made in specific areas of the Roman Empire; and more recently, as a description of a contemporary studio pottery technique supposedly inspired by ancient pottery. Usually roughly translated as 'sealed earth', the meaning of 'terra sigillata' is 'clay bearing little images', not 'clay with a sealed (impervious) surface'. The archaeological term is applied, however, to plain-surfaced pots as well as those decorated with figures in relief, because it does not refer to the decoration but to the makers stamp impressed in the bottom of the vessel.

Maiolica is tin-glazed pottery decorated in colours on a white background. The most renowned Italian maiolica is from the Renaissance period. These works were known as istoriato wares when depicting historical and mythical scenes. By the late 15th century, multiple locations, mainly in northern and central Italy, were producing sophisticated pieces for a luxury market in Italy and beyond. In France, maiolica developed as faience, in the Netherlands and England as delftware, and in Spain as talavera. In English, the spelling was anglicised to majolica, but the pronunciation usually preserved the vowel with an i as in kite.

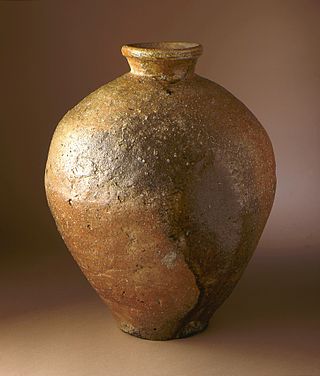

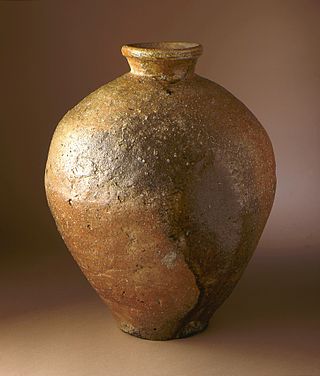

Shigaraki ware (信楽焼) is a type of stoneware pottery made in Shigaraki area, Japan. The kiln is one of the Six Ancient Kilns in Japan. Although figures representing the tanuki are a popular product included as Shigaraki ware, the kiln and local pottery tradition has a long history.

Chinese ceramics show a continuous development since pre-dynastic times and are one of the most significant forms of Chinese art and ceramics globally. The first pottery was made during the Palaeolithic era. Chinese ceramics range from construction materials such as bricks and tiles, to hand-built pottery vessels fired in bonfires or kilns, to the sophisticated Chinese porcelain wares made for the imperial court and for export. Porcelain was a Chinese invention and is so identified with China that it is still called "china" in everyday English usage.

Jun ware is a type of Chinese pottery, one of the Five Great Kilns of Song dynasty ceramics. Despite its fame, much about Jun ware remains unclear, and the subject of arguments among experts. Several different types of pottery are covered by the term, produced over several centuries and in several places, during the Northern Song dynasty (960–1127), Jin dynasty (1115–1234) and Yuan dynasty (1271–1368), and lasting into the early Ming dynasty (1368–1644).

Qingbai ware is a type of Chinese porcelain produced under the Song Dynasty and Yuan dynasty, defined by the ceramic glaze used. Qingbai ware is white with a blue-greenish tint, and is also referred to as Yingqing. It was made in Jiangxi province in south-eastern China, in several locations including Jingdezhen, and is arguably the first type of porcelain to be produced on a very large scale. However, it was not at the time a prestigious ware, and was mostly used for burial wares and exports, or a middle-rank Chinese market. The quality is very variable, reflecting these different markets; the best pieces can be very thin-walled.

Black-burnished ware is a type of Romano-British ceramic. Burnishing is a pottery treatment in which the surface of the pot is polished, using a hard smooth surface. The classification includes two entirely different pottery types which share many stylistic characteristics. Black burnished ware 1 (BB1), is a black, coarse and gritty fabric. Vessels are hand made. Black burnished ware 2 (BB2) is a finer, grey-coloured, wheel thrown fabric.

The basic chronology of the early town of Manda Island in the Lamu Archipelago of Kenya is divided into 6 different periods, based mostly on the types of imported pottery that has been found in different strata of the excavations. The first period, I, begins in the mid ninth century and is subdivided into four parts, a, b, c, and d, ending in the early eleventh century. Period II has two parts, A and B, though the divide between the two is rather vague and could be entirely arbitrary, and dates from the mid eleventh to the late twelfth for the former, and late twelfth to late thirteenth century for the latter. Period III runs from the late thirteenth century to the fourteenth when Period IV picks up and ends in the early Sixteenth. Period V covers the mid Sixteenth and all of the seventeenth, and the final period covers everything after the Seventeenth century.

Sandy ware, also known as Early Medieval Sandy ware, is a type of pottery found in Great Britain from the sixth through the fourteenth centuries. The pottery fabric is tempered with enough quartz sand mixed in with the clay for it to be visible in the fabric of the pot. Sandy ware was commonly used in Southeast England and the East Midlands.

Shelly ware, is a type of pottery found in Great Britain from the seventh through the twelfth centuries. Shelly ware includes Late Saxon Shelly ware, Early Medieval Shelly Ware, and Lincolnshire Shelly Wares. The pottery fabric is tempered with shell powder or reduced shell. Shelly ware was typically handmade until the tenth century, when potters transitioned to wheel-thrown pottery. Shelly wares were manufactured and distributed in the Upper Thames Valley, southeastern coastal areas of Britain and the East Midlands.

Surrey whiteware or Surrey white ware, is a type of lead-glazed pottery produced in Britain from the 13th to the 16th centuries. The white-fired sandy earthenware was produced largely from kilns in Surrey and along the Surrey-Hampshire border. Surrey whitewares were the most commonly used pottery in London during the late medieval period. There are four classes of Surrey whiteware: Kingston-type, Coarse Border ware, Cheam whiteware and Tudor Green ware.

Border ware is a type of post-medieval British pottery commonly used in the South of England, London and then later in the early American colonies beginning in the sixteenth and ending in the nineteenth century with a height of popularity and production in the seventeenth century. The lead-glazed, sandy earthenware was produced from kilns along the border between Hampshire and Surrey. There are two classes of Border ware, fine whitewares and fine redwares.

Shelly-sandy ware(SSW) is a type of medieval pottery produced in Great Britain. The pottery fabric is tempered with both sand and shell, most commonly quartz sand and ground-up shell. The fabric is generally dark grey in colour with brown oxidised surfaces. SSW was typically handmade until the potters transitioned to wheel-thrown pottery production. The pottery was manufactured and distributed primarily from 1140—1220 AD in the Greater London area.

Thetford ware is a type of English medieval pottery mass-produced in Britain between the late ninth and mid twelfth centuries AD. Manufactured in Norfolk and Ipswich, Suffolk, the pottery has a hard, sandy fabric, and is generally grey in colour. Most vessel types include cooking pots, bowls, jars, pitchers, and lamps.