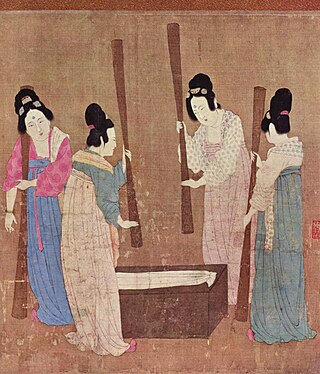

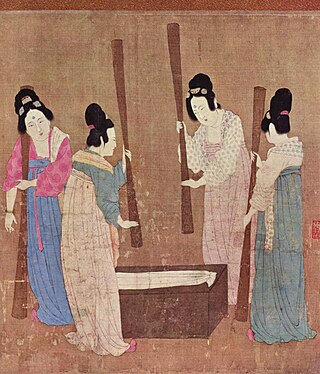

Silk is a natural protein fiber, some forms of which can be woven into textiles. The protein fiber of silk is composed mainly of fibroin and is produced by certain insect larvae to form cocoons. The best-known silk is obtained from the cocoons of the larvae of the mulberry silkworm Bombyx mori reared in captivity (sericulture). The shimmering appearance of silk is due to the triangular prism-like structure of the silk fibre, which allows silk cloth to refract incoming light at different angles, thus producing different colors.

Sericulture, or silk farming, is the cultivation of silkworms to produce silk. Although there are several commercial species of silkworms, the caterpillar of the domestic silkmoth is the most widely used and intensively studied silkworm. Silk was believed to have first been produced in China as early as the Neolithic period. Sericulture has become an important cottage industry in countries such as Brazil, China, France, India, Italy, Japan, Korea, and Russia. Today, China and India are the two main producers, with more than 60% of the world's annual production.

A Banarasi sari is a sari made in Varanasi, an ancient city which is also called Benares (Banaras). The saris are among the finest saris in India and are known for their gold and silver brocade or zari, fine silk and opulent embroidery. The saris are made of finely woven silk and are decorated with intricate designs, and, because of these engravings, are relatively heavy.

Vanavasi is a Town Panchayat in Mettur Taluka, Salem District, in the Indian state of Tamil Nadu.

Rajshahi silk is the name given to the silk products produced in Rajshahi, Bangladesh. It is famous because it is a high quality fabric used for clothing, especially for saris. In 2021, it was given Geographical indication status as a product of Bangladesh.

Silk In India, about 97% of the raw mulberry silk is produced in the Indian states of Karnataka, Andhra Pradesh, Tamil Nadu and West Bengal. Mysore and North Bangalore, the upcoming site of a US$20 million "Silk City", contribute to a majority of silk production. Another emerging silk producer is Tamil Nadu in the place in where mulberry cultivation is concentrated in Salem, Erode and Dharmapuri districts. Hyderabad, Andhra Pradesh and Gobichettipalayam, Tamil Nadu were the first locations to have automated silk reeling units.

Assam silk denotes the three major types of indigenous wild silks produced in Assam—golden muga, white pat and warm eri silk. The Assam silk industry, now centered in Sualkuchi, is a labor-intensive industry.

Thai silk is produced from the cocoons of Thai silkworms. Thailand's silkworm farmers cultivate both types of the domesticated silkworms that produce commercial silk: Samia ricini, commonly known as the eri silkworm, which produces matte eri silk, and the Bombyx mori, producer of the better known, glossy mulberry silk. The latter is by far the larger silk producer of the two.

Tussar silk is produced from larvae of several species of silkworms belonging to the moth genus Antheraea, including A. assamensis, A. paphia, A. pernyi, A. roylei, and A. yamamai. These silkworms live in the wild forests in trees belonging to Terminalia species and Shorea robusta, as well as other food plants such as jamun and oak found in South Asia, eating the leaves of the trees on which they live. Tussar silk is valued for its rich texture and natural, deep-gold colour, and varieties are produced in many countries, including China, India, Japan, and Sri Lanka.

The Kanchipuram silk sari is a type of silk sari made in the Kanchipuram region in Tamil Nadu, India. These saris are worn as bridal & special occasion saris by most women in Tamil Nadu, Kerala, Karnataka & Andhra Pradesh. It has been recognized as a Geographical indication by the Government of India in 2005–2006.

Baluchari Sari is a type of sari, a garment worn by women in Bangladesh and Indian states of West Bengal, Tripura and Assam. This particular type of sari originated in West Bengal and is known for depictions of mythological scenes on the anchal of the sari. It used to be produced in Murshidabad but presently Bishnupur and its surrounding areas of West Bengal are the only place where authentic Baluchari saris are produced. It takes approximately one week to produce one such sari. In 2011, the Baluchari Sari was granted the status of Geographical Indication for West Bengal in India.

Uppada Jamdani Saree is a silk sari style woven in Uppada of East Godavari district in the Indian state of Andhra Pradesh. It was registered as one of the geographical indication from Andhra Pradesh by Geographical Indications of Goods Act, 1999. Uppada Jamdani saris are known for their light weight.

Pochampally sari or Pochampalli ikat is a saree made in Bhoodan Pochampally, Yadadri Bhuvanagiri district, Telangana State, India. They have traditional geometric patterns in "Paagadu Bandhu" (Ikat) style of dyeing. The intricate geometric designs find their way into sarees and dress materials. The Indian government's official airplane company, Air India, has its cabin crew wear specially designed Pochampally silk sarees.

Kovai Cora cotton or Kovai Kora cotton is a type of saree made in the Coimbatore region in Tamil Nadu, India. It has been recognized as a Geographical indication by the Government of India in 2014–15. The Devanga community are pioneers in weaving Kovai Kora cotton saris. 82 Weaver cooperative Societies in Coimbatore, Tiruppur and Erode are authorised to sell Kovai Kora cotton saris.

Handloom saris are a traditional textile art of Bangladesh and India. The production of handloom saris is important for economic development in rural India.

Dharmavaram handloom pattu sarees and paavadas are textiles woven by hand with mulberry silk and zari. They are made in Dharmavaram of Anantapur district in the Indian state of Andhra Pradesh. It was registered as one of the geographical indication from Andhra Pradesh by Geographical Indications of Goods Act, 1999.

Habaspuri is a cotton-based traditional handloom textiles of Odisha, India. Habaspuri sari is a major product of this textile. The Bhulia weavers of Chicheguda, Kalahandi district, Odisha are originally attributed for weaving of the Habaspuri fabric. For its uniqueness in weaving, design and production, it has been identified as one of the 14 Geographical Indications of Odisha.

Kotpad Handloom is a vegetable-dyed fabric woven by the tribal weavers of the Mirgan community of Kotpad village in Koraput district, Odisha, India. Cotton sarees with solid border and Pata Anchal, duppatta with typical Buties / motifs, Scolrfs on cotton, silk, handloom stoles, and dress materials are all dyed with organic dyes. The natural dye is manufactured from the aul tree grown in this area. The Kotpad tussar silk saree with tribal art and Kotpad handloom fabrics with natural color is its specialty.

Madurai Sungudi is design of Madurai in the Indian state of Tamil Nadu, which is an exclusive textile product traditionally produced using tie and dye method by the Saurashtrians who migrated to Madurai under the patronage of King Thirumalai Naicker in the 17th century. The fabric's traditional popular use is as a saree; the fabric is now also used to make shirts, salwars, shawls, handbags, bed sheets and pillow cases. The product has been given protection under the GI registration act.

Murshidabad silk is produced in Murshidabad district of West Bengal. This silk is produced from mulberry silkworms reared on mulberry trees. Murshidabad silk is known for its premium quality. This silk is very fine, light weight and easy to drape. Two famous saris produced from Murshidabad silk are Baluchari and Gorood.