Woolley Colliery is a village in Wakefield district in West Yorkshire, England. The village is near the border with South Yorkshire. The former colliery was in the Wakefield Rural Ward in West Yorkshire. The village is known locally as Mucky Woolley, as a tribute to its coalmining heritage and to distinguish it from the more affluent village of Woolley two miles away.

Caphouse Colliery, originally known as Overton Colliery, was a coal mine in Overton, near Wakefield, West Yorkshire, England. It was situated on the Denby Grange estate owned by the Lister Kaye family, and was worked from the 18th century until 1985. It reopened as the Yorkshire Mining Museum in 1988, and is now the National Coal Mining Museum for England.

The Maltby Main Colliery was a coal mine located 7 miles (11 km) east of Rotherham on the eastern edge of Maltby, South Yorkshire, England. The mine was closed in 2013.

Kellingley Colliery, known affectionately as the 'Big K', was a deep coal mine in North Yorkshire, England, 3.6 miles (5.8 km) east of Ferrybridge power station. It was owned and operated by UK Coal.

The South Yorkshire Coalfield is so named from its position within Yorkshire. It covers most of South Yorkshire, West Yorkshire and a small part of North Yorkshire. The exposed coalfield outcrops in the Pennine foothills and dips under Permian rocks in the east. Its most famous coal seam is the Barnsley Bed. Coal has been mined from shallow seams and outcrops since medieval times and possibly earlier.

Harworth Colliery was a colliery near the town of Harworth Bircotes in Bassetlaw, Nottinghamshire, England.

Bedwas Navigation Colliery was a coal mine in the small Welsh village of Bedwas, two miles (3.2 km) north of Caerphilly. The colliery opened in 1913, and closed after the miners' strike of 1984-85.

Frickley & South Elmsall Colliery was opened by the Carlton Main Colliery Company Ltd in 1903 in South Elmsall, in Yorkshire, England.

Selby coalfield was a large-scale deep underground mine complex based around Selby, North Yorkshire, England, with pitheads at Wistow Mine, Stillingfleet Mine, Riccall Mine, North Selby Mine, Whitemoor Mine and at Gascoigne Wood Mine. All coal was brought to the surface and treated at Gascoigne Wood before being distributed by rail. The primary purpose of the pit was to supply coal for electrical power generation; much of it was used in the nearby Aire valley power stations.

Penallta Colliery was a coal mine, located close to Hengoed in the Rhymney Valley in the South Wales Valleys. A coal mine which in 1935 held the European record for coal wound in a 24-hour period, it is now the site of an original redevelopment project which will make use of the former pit head buildings.

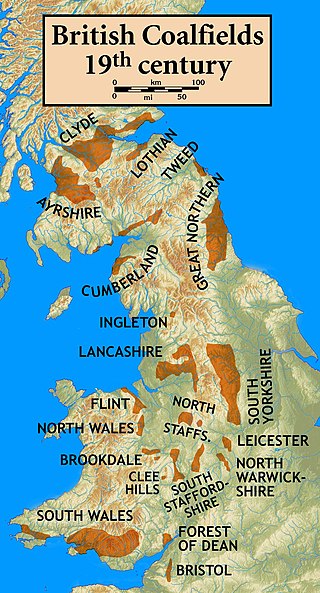

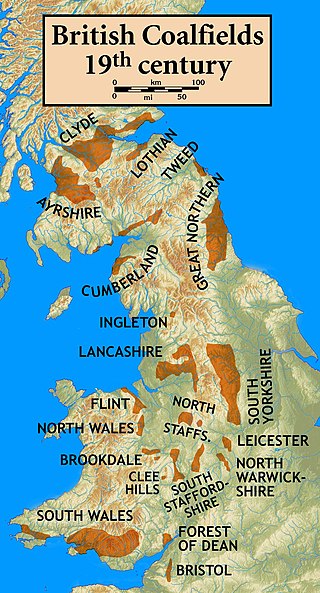

Coal mining in the United Kingdom dates back to Roman times and occurred in many different parts of the country. Britain's coalfields are associated with Northumberland and Durham, North and South Wales, Yorkshire, the Scottish Central Belt, Lancashire, Cumbria, the East and West Midlands and Kent. After 1972, coal mining quickly collapsed and had practically disappeared by the 21st century. The consumption of coal—mostly for electricity—fell from 157 million tonnes in 1970 to 18 million tonnes in 2016, of which 77% was imported from Colombia, Russia, and the United States. Employment in coal mines fell from a peak of 1,191,000 in 1920 to 695,000 in 1956, 247,000 in 1976, 44,000 in 1993, 2,000 in 2015, and to 360 in 2022.

Ellington Colliery, was a coal mine situated to the south of the village of Ellington in Northumberland, England. The colliery was the last deep coal mine in the north east of England. At one time, the deepest part of the mine was 800 metres (2,600 ft) and it extended 15 miles (24 km) under the North Sea. During the 1980s, the pit was known as the biggest undersea mine in the world and produced 69% of the mined coal in Northumberland.

Markham Main Colliery was a coal mine in Armthorpe, on the eastern edge of Doncaster, South Yorkshire, England. It could be seen, and was a landmark, from the nearby M18.

Haig Colliery was a coal mine in Whitehaven, Cumbria, in north-west England. The mine was in operation for almost 70 years and produced high volatile strongly caking general purpose coal which was used in the local iron making industry, gas making and domestic fires. In later years, following closure of Workington Steelworks in 1980, it was used in electricity generation at Fiddler's Ferry. Situated on the coast, the underground workings of the mine spread westwards out under the Irish Sea and mining was undertaken at over 4 miles (6.4 km) out underneath the sea bed.

Wheldale Colliery was a coal mine located in Castleford, Yorkshire, England which produced coal for 117 years. It was accessed from Wheldon Road.

Barrow Colliery was a coal mine in Worsborough, South Yorkshire, England. It was first dug in 1873, with the first coal being brought to the surface in January 1876. It was the scene of a major incident in 1907 when seven miners died. After 109 years of coaling operations, the mine was closed in May 1985.

Bentley Colliery was a coal mine in Bentley, near Doncaster in South Yorkshire, England, that operated between 1906 and 1993. In common with many other mines, it suffered disasters and accidents. The worst Bentley disaster was in 1931 when 45 miners were killed after a gas explosion. The site of the mine has been converted into a woodland.

Monckton Coke Works was a coking plant near Royston in South Yorkshire, England. The plant opened in 1884 and was closed 130 years later in 2014, being one of the last remnants of the coal industry in Yorkshire. In the 21st century, it was known as being the last independent coke works in the United Kingdom. For many years it was known for its high-quality coking coal, even being exported to coal-rich South Africa for use in steelmaking. However, in 2013/2014, the market was swamped with cheap imports from the Far East, spelling the demise of Monckton due to it being uneconomical.

Parkside Colliery was a coal mine in Newton-le-Willows, in the historic county of Lancashire, but from 1974, until its closure in 1993, it was in Metropolitan Borough of St Helens, in the metropolitan county of Merseyside. It was always described as being in Lancashire, and was the last deep coal mine operating in the Lancashire Coalfield upon closure.

Harworth Group plc ("Harworth") is a property developer that specialises in regenerating brownfield sites in Yorkshire, the Midlands, and North West England. The company is headquartered in Rotherham in South Yorkshire. It is listed on the London Stock Exchange and is a member of the FTSE SmallCap Index.