Poole Ironworks

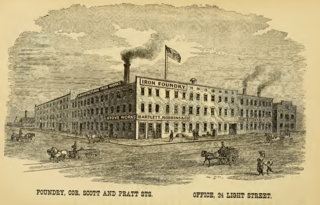

In 1843, on the northern edge of Baltimore, Poole and his first partner, William Fergusson (1816–1863), hired a small crew of metalworkers and opened for business as the Baltimore Ironworks (generally known as Poole & Fergusson). [8]

During the 1840s and 1850s a tectonic shift had begun in the use of natural resources—away from wood (and its derivative, charcoal), long the nation's primary source of heat, and toward coal, soon to become the dominant fuel for heating homes and factories, for driving steam engines, and for smelting iron. [9] By using coal instead of charcoal (as a source of heat and carbon), together with a process known as hot blast (blowing hot air into smelting furnaces), operators could build larger, more efficient furnaces and vastly increase their production of pig iron (the raw material for finished iron-based products). What had been scarce and expensive became plentiful and affordable—helping set off a wave of industrial diversification that laid the foundation for the Poole company's expansion.

In 1851, because of disagreements over money and management, Poole ended his partnership with William Fergusson and took on, as his new partner, German H. Hunt (1828–1907), in a business they named the Union Works (generally known as Poole & Hunt). During their collaboration—until 1888, when Hunt retired—Poole managed internal operations of the ironworks; Hunt directed sales, bidding on contracts, and relations with the public. [10]

In 1853, after a fire in their foundry and machine shop, and a city-wide strike of metalworkers, the partners moved their operations from Baltimore to what was then the village of Woodberry, [11] a few miles north of the city. On farmland beside the Jones Falls (falls is a local word for river), they constructed a plant fifty percent larger than the in-town ironworks. Each craft had its own shop of one story; ample space between shops made possible the subsequent enlargement of the business. [12]

It was during this period of transition—to a new partnership and a new location—that Poole's company came to national attention with its work on the United States Capitol in Washington, D.C. in the 1850s. Responsible for enlarging and modernizing the overcrowded building, the architect of the project, Thomas U. Walter made architectural history when he selected iron instead of marble for the thirty-six columns (known as a peristyle) that surround the base of the dramatic new dome he designed.

Forty miles away, Poole set precedent, too, when he cast the columns in deep pits in his new foundry. Molding iron in that way and for this purpose had not been accomplished before. The Poole company would go on to supply a total of 2.8 million pounds of structural iron for the new Capitol, chiefly for the dome. [13] For the Capitol project, Poole and Hunt took their instructions from Montgomery C. Meigs of the U.S. Army Corps of Engineers, superintendent of Capitol construction during the 1850s. (Meigs was later appointed by President Lincoln as Quartermaster of the Union Army during the Civil war). [14]

Simultaneous with the Capitol Project, Meigs was responsible for the building of the Washington Aqueduct, and contracted with the Poole company to supply a derrick, a steam engine, and a stone-smoothing machine for that project. [15] The Poole company worked again in Washington, D.C., in the 1880s, when its hydraulic pumps on barges sucked up muck and debris from the bottom of the Potomac River and, via a pipeline, deposited the material thousands of feet away, on the edge of the city, where it formed the ground for East Potomac Park, home to the Lincoln Memorial and other monuments. [16]

Over his lifetime, Poole was granted eleven patents—one for improving the durability of wheels on railroad rolling stock and another for a device that accelerated the heating of water before it entered a boiler. [17] His most successful invention was a revolving pan that mixed ingredients for commercial fertilizer, a mechanism that was widely adopted in the emerging fertilizer industry during the 1870s and 1880s. [18]

Poole’s openness to the innovations of others freshened his company’s array of products and added to its profitability. George Babcock and Stephen Wilcox, Jr. of Providence licensed the Poole company to manufacture their patented safety boiler. Its water was dispersed in many small tubes that resisted exploding under pressure, a significant improvement over conventional, so-called shell boilers, whose water was concentrated in a single container which, when overheated, could exploded easily and with fatal consequences. [19]

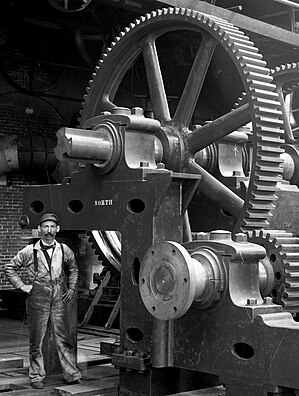

Robert Poole and Englishman John Walker collaborated on the manufacture and use of semi-automated, gear-molding machinery (an advance over cast and machine-cut gears) that, reportedly, sped production and improved their quality. [20] By the end of the nineteenth century, the Poole company was ranked as the leading maker of diversified industrial gearing in the United States—with gears that fit into a child's hand and stood as high as an elephant. [21]

Poole's most important alliance was with James Leffel of Springfield, Ohio, inventor of the so-called double turbine water wheel, a highly efficient mechanism that converted the energy of moving water into rotary power that drove machinery. [22] Leffel’s turbine, and turbines that Poole engineers designed on their own, enable the company to become a significant competitor in the generation and distribution of industrial power, particularly in textile mills in the South after the Civil War and in the paper-making industry in the Northeast. [23] The company’s largest single order—for forty custom-made turbines—was for the hydroelectric station at York Haven, Pennsylvania, beside the Susquehanna River. Twenty of these turbines continue to turn electricity-producing generators today. [24]

“Robert Poole was an exceptional engineer with remarkable insight into the future and anticipation of big things in engineering," wrote editor and author E.A. Suverkrop, in the American Machinist . (vol.52, no.3, 15 January 1920)