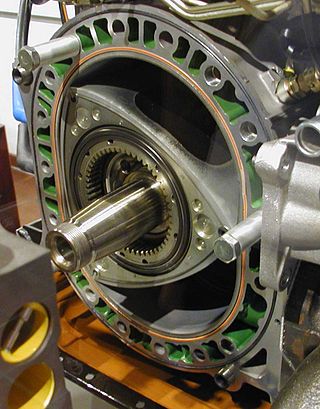

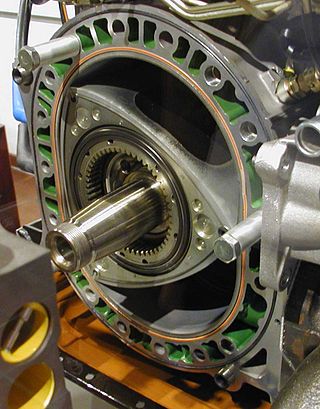

The Wankel engine is a type of internal combustion engine using an eccentric rotary design to convert pressure into rotating motion. The concept was proven by German engineer Felix Wankel, followed by a commercially feasible engine designed by German engineer Hanns-Dieter Paschke. The Wankel engine's rotor, which creates the turning motion, is similar in shape to a Reuleaux triangle, with the sides having less curvature. The rotor spins inside a figure-eight-like epitrochoidal housing around a fixed-toothed gearing. The midpoint of the rotor moves in a circle around the output shaft, rotating the shaft via a cam.

A two-strokeengine is a type of internal combustion engine that completes a power cycle with two strokes of the piston in one revolution of the crankshaft. A four-stroke engine requires four strokes of the piston to complete a power cycle in two crankshaft revolutions. In a two-stroke engine, the end of the combustion stroke and the beginning of the compression stroke happen simultaneously, with the intake and exhaust functions occurring at the same time.

The Honda Magna is a cruiser motorcycle made from 1982 to 1988 and 1994 to 2003 and was the second Honda to use their new V4 engine shared with the VF750S Sabre and a few years later a related engine was fitted to the VF750F 'Interceptor', the later models used a retuned engine from the VFR750F with fins added to the outside of the engine. The engine technology and layout was a descendant of Honda's racing V4 machines, such as the NS750 and NR750. The introduction of this engine on the Magna and the Sabre in 1982, was a milestone in the evolution of motorcycles that would culminate in 1983 with the introduction of the Interceptor V4. The V45's performance is comparable to that of Valkyries and Honda's 1800 cc V-twin cruisers. However, its mix of performance, reliability, and refinement was overshadowed by the more powerful 1,098 cc "V65" Magna in 1983.

The Mazda Wankel engines are a family of Wankel rotary combustion car engines produced by Mazda.

The Yamaha XS650 is a mid-size motorcycle that was made by the Yamaha Motor Company. The standard model was introduced in October 1969, and produced until 1979. The "Special" cruiser model was introduced in 1978 and produced until 1985. The XS650 began with the 1955 Hosk SOHC 500 twin. After about 10 years of producing 500 twin, Hosk engineers designed a 650 cc twin. Later Showa Corporation acquired the Hosk company, and in 1960 Yamaha acquired Showa, with Hosk's early design of 650 cc twin.

A motorcycle engine is an engine that powers a motorcycle. Motorcycle engines are typically two-stroke or four-stroke internal combustion engines, but other engine types, such as Wankels and electric motors, have been used.

The Suzuki GSX-R750 is a sports motorcycle made by Suzuki since 1984. It was introduced at the Cologne Motorcycle Show in October 1984 as a motorcycle of the GSX-R series for the 1985 model year.

The Yamaha FZR1000 is a motorcycle produced by Yamaha from 1987 to 1995. Classed as a sports motorcycle.

Hercules was a brand of bicycle and motorcycle manufactured in Germany.

The Hyosung GT250 is part of Hyosung's GT series. It shares many parts with its larger displacement siblings and it came in two flavors: GT250 (Comet) (naked bike) and GT250R (sports bike). The GT250 Comet came out in 2004, with the "Comet" suffix being dropped for the newly fuel injected 2010 model. The GT250R came out at the same time and although it seems it never officially had the "Comet" suffix, early fairings do seem to have Comet stickers. Specs are mostly the same, making the appearance the main difference between the two.

The Norton Classic is a rotary-engined motorcycle built in 1987 by Norton as a special edition of just 100 machines.

The Yamaha TX500 is a two-cylinder standard motorcycle built by Yamaha and sold in 1973 and 1974. Early models closely resembled the Triumph Bonneville in style. In 1975 the bike was renamed XS500 and then continued to be updated until 1978 when sales ended in the USA. In Europe, the model was available through 1980.

The GT series is a series of two-stroke chain drive motorcycles manufactured and marketed by Suzuki for model years 1972–1977, with a range of engine capacities and cylinder counts. Certain markets received the GT380 until model year 1980.

The General Motors Rotary Combustion Engine (GMRCE) is an internal combustion Wankel engine which uses a rotary design to convert pressure into a rotating motion instead of using reciprocating pistons. In November 1970, GM paid $50 million, ($392,287,918 in 2023 dollars ), for initial licenses to produce their version of the Wankel rotary engine, and GM President Ed Cole initially projected its release in three years. Chevrolet, with impetus from Pete Estes and John DeLorean, as well as Ed Cole worked on the Wankel. Bob Templin was the chief executive in charge of rotary-engine research at the GM Tech Center in Warren, Michigan, but Ed Cole would leave his office in Detroit twice a week for the trip to Warren, taking charge of the program. The engine was initially targeted for an October 1973 introduction as a 1974 Chevrolet Vega option. Its mediocre fuel economy and the ill-timed Arab oil embargo were contributing factors to end the GM rotary program.

The MidWest AE series are lightweight, liquid-cooled, single- and twin-rotor Wankel engines, with dual ignition, designed for light aircraft. They were produced by Mid-West Engines Ltd. at Staverton Airport, Gloucestershire, UK.

A total-loss oiling system is an engine lubrication system whereby oil is introduced into the engine and then either burned or ejected overboard. Now rare in four-stroke engines, total loss oiling is still used in many two-stroke engines.

An internal combustion engine is a heat engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons, turbine blades, a rotor, or a nozzle. This force moves the component over a distance. This process transforms chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to.

The Hercules W-2000 is a motorcycle which was made by Hercules in Germany. It was the first production motorcycle with a Wankel engine.

David W. Garside is an inventor and former project engineer at BSA's Kitts Green research facility. He is notable for having developed an air-cooled twin-rotor Wankel motorcycle engine which powered the Norton Classic road bike. Although the Classic was not the first production rotary-engined bike, it was significantly lighter, smoother, more powerful and better-handling than the contemporary Suzuki RE5.

The Suzuki A100 is a Japanese motorcycle from the Suzuki Motor Corporation with production starting in 1966.Similar models were produced by Yamaha and Kawasaki with the YB100 & KH100 models, also with a single-cylinder two-stroke engine and rotary valve being examples.