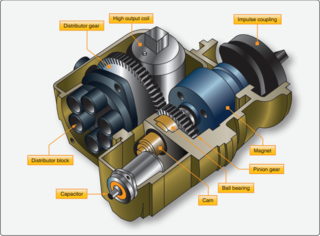

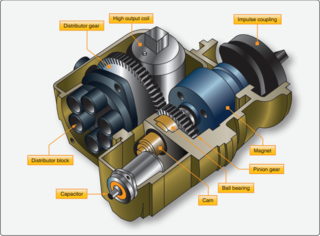

An ignition magneto is an older type of ignition system used in spark-ignition engines. It uses a magneto and a transformer to make pulses of high voltage for the spark plugs. The older term "high-tension" means "high-voltage".

A Tesla coil is an electrical resonant transformer circuit designed by inventor Nikola Tesla in 1891. It is used to produce high-voltage, low-current, high-frequency alternating-current electricity. Tesla experimented with a number of different configurations consisting of two, or sometimes three, coupled resonant electric circuits.

An induction coil or "spark coil" is a type of electrical transformer used to produce high-voltage pulses from a low-voltage direct current (DC) supply. To create the flux changes necessary to induce voltage in the secondary coil, the direct current in the primary coil is repeatedly interrupted by a vibrating mechanical contact called an interrupter. Invented in 1836 by the Irish-Catholic priest Nicholas Callan, also independently by American inventor Charles Grafton Page, the induction coil was the first type of transformer. It was widely used in x-ray machines, spark-gap radio transmitters, arc lighting and quack medical electrotherapy devices from the 1880s to the 1920s. Today its only common use is as the ignition coils in internal combustion engines and in physics education to demonstrate induction.

A spark gap consists of an arrangement of two conducting electrodes separated by a gap usually filled with a gas such as air, designed to allow an electric spark to pass between the conductors. When the potential difference between the conductors exceeds the breakdown voltage of the gas within the gap, a spark forms, ionizing the gas and drastically reducing its electrical resistance. An electric current then flows until the path of ionized gas is broken or the current reduces below a minimum value called the "holding current". This usually happens when the voltage drops, but in some cases occurs when the heated gas rises, stretching out and then breaking the filament of ionized gas. Usually, the action of ionizing the gas is violent and disruptive, often leading to sound, light, and heat.

Ignition systems are used by heat engines to initiate combustion by igniting the fuel-air mixture. In a spark ignition versions of the internal combustion engine, the ignition system creates a spark to ignite the fuel-air mixture just before each combustion stroke. Gas turbine engines and rocket engines normally use an ignition system only during start-up.

A contact breaker is a type of electrical switch, found in the ignition systems of spark-ignition internal combustion engines. The switch is automatically operated by a cam driven by the engine. The timing of operation of the switch is set so that a spark is produced at the right time to ignite the compressed air/fuel mixture in the cylinder of the engine. A mechanism may be provided to slightly adjust timing to allow for varying load on the engine. Since these contacts operate frequently, they are subject to wear, causing erratic ignition of the engine. More recent engines use electronic means to trigger the spark, which eliminated contact wear and allows computer control of ignition timing.

A distributor is an electric and mechanical device used in the ignition system of older spark ignition engines. The distributor's main function is to route electricity from the ignition coil to each spark plug at the correct time.

A thyratron is a type of gas-filled tube used as a high-power electrical switch and controlled rectifier. Thyratrons can handle much greater currents than similar hard-vacuum tubes. Electron multiplication occurs when the gas becomes ionized, producing a phenomenon known as a Townsend discharge. Gases used include mercury vapor, xenon, neon, and hydrogen. Unlike a vacuum tube (valve), a thyratron cannot be used to amplify signals linearly.

A DC-to-DC converter is an electronic circuit or electromechanical device that converts a source of direct current (DC) from one voltage level to another. It is a type of electric power converter. Power levels range from very low to very high.

A pulse-forming network (PFN) is an electric circuit that accumulates electrical energy over a comparatively long time, and then releases the stored energy in the form of a relatively square pulse of comparatively brief duration for various pulsed power applications. In a PFN, energy storage components such as capacitors, inductors or transmission lines are charged by means of a high-voltage power source, then rapidly discharged into a load through a high-voltage switch, such as a spark gap or hydrogen thyratron. Repetition rates range from single pulses to about 104 per second. PFNs are used to produce uniform electrical pulses of short duration to power devices such as klystron or magnetron tube oscillators in radar sets, pulsed lasers, particle accelerators, flashtubes, and high-voltage utility test equipment.

A Marx generator is an electrical circuit first described by Erwin Otto Marx in 1924. Its purpose is to generate a high-voltage pulse from a low-voltage DC supply. Marx generators are used in high-energy physics experiments, as well as to simulate the effects of lightning on power-line gear and aviation equipment. A bank of 36 Marx generators is used by Sandia National Laboratories to generate X-rays in their Z Machine.

A spark-gap transmitter is an obsolete type of radio transmitter which generates radio waves by means of an electric spark. Spark-gap transmitters were the first type of radio transmitter, and were the main type used during the wireless telegraphy or "spark" era, the first three decades of radio, from 1887 to the end of World War I. German physicist Heinrich Hertz built the first experimental spark-gap transmitters in 1887, with which he proved the existence of radio waves and studied their properties.

High energy ignition, also known as H.E.I., is an electronic ignition system designed by the Delco-Remy Division of General Motors. It was used on all GM vehicles, at least in the North American market, from 1975 through the mid-1980s. The system is an electronic system that requires no scheduled maintenance, provides up to 35,000 volts to fire the spark plugs and increase spark plug life, especially when unleaded fuel is used. The HEI system has 40% more voltage output and 85% higher energy level than conventional breaker point systems to fire lean fuel mixtures even under adverse conditions.

The Trionic 8 is an advanced engine management system in the Trionic series, created by Saab Automobile. It is used in both Saab 9-3 and Opel Vectra vehicles, and is available with 150, 175 and 210 horsepower (160 kW) engines. It will also be used for a flexifuel version starting production spring 2007. Saab Trionic T8 has been developed by Saab and is a very advanced engine management system. The Engine Control Module (ECM) is used principally to regulated the air mass, fuel and ignition timing.

An ignition coil is used in the ignition system of a spark-ignition engine to transform the battery voltage to the much higher voltages required to operate the spark plug(s). The spark plugs then use this burst of high-voltage electricity to ignite the air-fuel mixture.

Trionic T5.5 is an engine management system in the Saab Trionic range. It controls ignition, fuel injection and turbo boost pressure. The system was introduced in the 1993 Saab 9000 2.3 Turbo with B234L and B234R engine.

Capacitors have many uses in electronic and electrical systems. They are so ubiquitous that it is rare that an electrical product does not include at least one for some purpose. Capacitors allow only AC signals to pass when they are charged blocking DC signals. The main components of filters are capacitors. Capacitors have the ability to connect one circuit segment to another. Capacitors are used by Dynamic Random Access Memory (DRAM) devices to represent binary information as bits.

Inductive discharge ignition systems were developed in the 19th century as a means to ignite the air–fuel mixture in the combustion chamber of internal combustion engines. The first versions were low tension coils, then low-tension and in turn high-tension magnetos, which were offered as a more effective alternative to the older-design hot-tube ignitors that had been utilized earlier on hot tube engines. With the advent of small stationary engines; and with the development of the automobile, engine-driven tractors, and engine-driven trucks; first the magneto and later the distributor-type systems were utilized as part of an efficient and reliable engine ignition system on commercially available motorized equipment. These systems were in widespread use on all cars and trucks through the 1960s. Manufacturers such as Ford, General Motors, Chrysler, Citroen, Mercedes, John Deere, International Harvester, and many others incorporated them into their products. The inductive discharge system is still extensively used today.

The Delco ignition system, also known as the Kettering ignition system, points and condenser ignition or breaker point ignition, is a type of inductive discharge ignition system invented by Charles F. Kettering. It was first sold commercially on the 1912 Cadillac and was manufactured by Delco. Over time, it was used extensively by all automobile and truck manufacturers on spark ignition, i.e., gasoline engines. Today it is still widely used in coil-on-plug, coil-near-plug and in coil packs in distributorless ignitions. An alternative system used in automobiles is capacitor discharge ignition, primarily found now as aftermarket upgrade systems. Electronic ignition was a common term for Kettering inductive ignition with the points replaced with an electronic switch such as a transistor.

A trembler coil, buzz coil or vibrator coil is a type of high-voltage ignition coil used in the ignition system of early automobiles, most notably the Benz Patent-Motorwagen and the Ford Model T. Its distinguishing feature is a vibrating magnetically-activated contact called a trembler or interrupter, which breaks the primary current, generating multiple sparks during each cylinder's power stroke. Trembler coils were first used on the 1886 Benz automobile, and were used on the Model T until 1927.