Fuel injection is the introduction of fuel in an internal combustion engine, most commonly automotive engines, by the means of an injector. This article focuses on fuel injection in reciprocating piston and Wankel rotary engines.

A carburetor is a device used by a gasoline internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the Venturi tube in the main metering circuit, though various other components are also used to provide extra fuel or air in specific circumstances.

Aircraft engine controls provide a means for the pilot to control and monitor the operation of the aircraft's powerplant. This article describes controls used with a basic internal-combustion engine driving a propeller. Some optional or more advanced configurations are described at the end of the article. Jet turbine engines use different operating principles and have their own sets of controls and sensors.

A fuel pump is a component used in many liquid-fuelled engines to transfer the fuel from the fuel tank to the device where it is mixed with the intake air.

An inlet manifold or intake manifold is the part of an internal combustion engine that supplies the fuel/air mixture to the cylinders. The word manifold comes from the Old English word manigfeald and refers to the multiplying of one (pipe) into many.

Dieseling or engine run-on is a condition that can occur in spark-plug-ignited, gasoline-powered internal combustion engines, whereby the engine keeps running for a short period after being turned off, drawing fuel through the carburetor, into the engine and igniting it without a spark.

Manifold vacuum, or engine vacuum in an internal combustion engine is the difference in air pressure between the engine's intake manifold and Earth's atmosphere.

A ram-air intake is any intake design which uses the dynamic air pressure created by vehicle motion, or ram pressure, to increase the static air pressure inside of the intake manifold on an internal combustion engine, thus allowing a greater massflow through the engine and hence increasing engine power.

A backfire or afterburn is combustion or an explosion produced by a running internal combustion engine that occurs in the exhaust system, rather than inside the combustion chamber. It is also sometimes referred to as an afterfire, especially in cases where the word backfire is used to mean a fuel burn that occurs while an intake valve is open, causing the fire to move backward through the system and out through the intake instead of the exhaust. When the flame moves backward it may also be called a "pop-back". A backfire can be caused either by ignition that happens with an exhaust valve open or unburnt fuel making its way into the hot exhaust system. A visible flame may momentarily shoot out of the exhaust pipe. A backfire is often a sign that the engine is improperly tuned.

Carburetor heat is a system used in automobile and piston-powered light aircraft engines to prevent or clear carburetor icing. It consists of a moveable flap which draws hot air into the engine intake. The air is drawn from the heat stove, a metal plate around the exhaust manifold.

A nitro engine generally refers to an engine powered with a fuel that contains some portion of nitromethane mixed with methanol. Nitromethane is a highly combustible substance that is generally only used in very specifically designed engines found in Top Fuel drag racing and in miniature internal combustion engines in radio control, control line and free flight model aircraft.

In internal combustion engines with carburetors, a choke valve or choke modifies the air pressure in the intake manifold, thereby altering the air–fuel ratio entering the engine. Choke valves are generally used in naturally aspirated engines to supply a richer fuel mixture when starting the engine. Most choke valves in engines are butterfly valves mounted upstream of the carburetor jet to produce a higher partial vacuum, which increases the fuel draw.

A throttle is a mechanism by which fluid flow is managed by constriction or obstruction.

The Quadrajet is a four barrel carburetor, made by the Rochester Products Division of General Motors. Its first application was the new-for-1965 Chevy 396ci engine. Its last application was on the 1990 Oldsmobile 307 V8 engine, which was last used in the Cadillac Brougham and full size station wagons made by Chevrolet, Pontiac, Oldsmobile, and Buick.

Miss Shilling's orifice was a very simple technical device created to counter engine cut-outs experienced during negative G manoeuvres in early Spitfire and Hurricane fighter aeroplanes during the Battle of Britain. Officially called the R.A.E. restrictor, it was referred to under various names, such as Miss Tilly's diaphragm or the Tilly orifice in reference to its inventor, Beatrice "Tilly" Shilling.

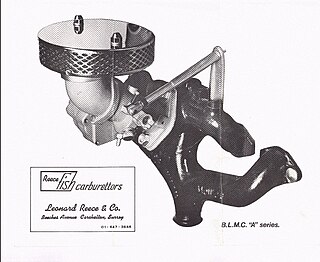

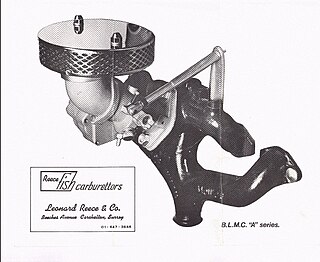

The Reece-Fish carburetor was a carburetor used by Mini Se7en racers in the 60s and 70s.

The SU carburettor was a constant-depression carburettor made by a British manufacturer of that name or its licensees in various designs spanning most of the twentieth century.

Internal combustion engines come in a wide variety of types, but have certain family resemblances, and thus share many common types of components.

Of the three types of carburetors used on large, high-performance aircraft engines manufactured in the United States during World War II, the Bendix-Stromberg pressure carburetor was the one most commonly found. The other two carburetor types were manufactured by Chandler Groves and Chandler Evans Control Systems (CECO). Both of these types of carburetors had a relatively large number of internal parts, and in the case of the Holley Carburetor, there were complications in its "variable venturi" design.

Manifold injection is a mixture formation system for internal combustion engines with external mixture formation. It is commonly used in engines with spark ignition that use petrol as fuel, such as the Otto engine, and the Wankel engine. In a manifold-injected engine, the fuel is injected into the intake manifold, where it begins forming a combustible air-fuel mixture with the air. As soon as the intake valve opens, the piston starts sucking in the still forming mixture. Usually, this mixture is relatively homogeneous, and, at least in production engines for passenger cars, approximately stoichiometric; this means that there is an even distribution of fuel and air across the combustion chamber, and enough, but not more air present than what is required for the fuel's complete combustion. The injection timing and measuring of the fuel amount can be controlled either mechanically, or electronically. Since the 1970s and 1980s, manifold injection has been replacing carburettors in passenger cars. However, since the late 1990s, car manufacturers have started using petrol direct injection, which caused a decline in manifold injection installation in newly produced cars.