A carburetor is a device used by a gasoline internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the Venturi tube in the main metering circuit, though various other components are also used to provide extra fuel or air in specific circumstances.

Orography is the study of the topographic relief of mountains, and can more broadly include hills, and any part of a region's elevated terrain. Orography falls within the broader discipline of geomorphology. The term orography comes from the Greek: όρος, hill, γραφία, to write.

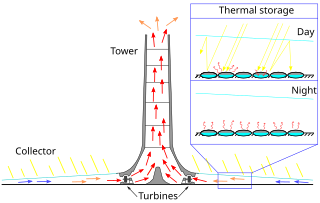

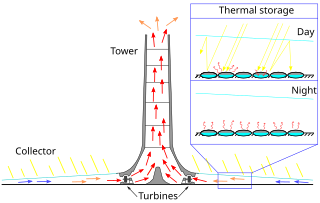

The solar updraft tower (SUT) is a design concept for a renewable-energy power plant for generating electricity from low temperature solar heat. Sunshine heats the air beneath a very wide greenhouse-like roofed collector structure surrounding the central base of a very tall chimney tower. The resulting convection causes a hot air updraft in the tower by the chimney effect. This airflow drives wind turbines, placed in the chimney updraft or around the chimney base, to produce electricity.

The Continental C90 and O-200 are a family of air-cooled, horizontally opposed, four-cylinder, direct-drive aircraft engines of 201 in³ displacement, producing between 90 and 100 horsepower.

Briggs & Stratton Corporation is an American manufacturer of gasoline engines with headquarters in Wauwatosa, Wisconsin.

A particulate air filter is a device composed of fibrous, or porous materials which removes solid particulates such as dust, pollen, mold, and bacteria from the air. Filters containing an adsorbent or catalyst such as charcoal (carbon) may also remove odors and gaseous pollutants such as volatile organic compounds or ozone. Air filters are used in applications where air quality is important, notably in building ventilation systems and in engines.

The Continental O-170 engine is the collective military designation for a family of small aircraft engines, known under the company designation of A50, A65, A75 and A80. The line was designed and built by Continental Motors commencing in the 1940s. It was employed as the powerplant for civil and military light aircraft.

A ram-air intake is any intake design which uses the dynamic air pressure created by vehicle motion, or ram pressure, to increase the static air pressure inside of the intake manifold on an internal combustion engine, thus allowing a greater massflow through the engine and hence increasing engine power.

An intake is an opening, structure or system through which a fluid is admitted to a space or machine as a consequence of a pressure differential between the outside and the inside. The pressure difference may be generated on the inside by a mechanism, or on the outside by ram pressure or hydrostatic pressure. Flow rate through the intake depends on pressure difference, fluid properties, and intake geometry.

The Computerized Engine Control or Computerized Emission Control (CEC) system is an engine management system designed and used by American Motors Corporation (AMC) and Jeep on 4- and 6-cylinder engines of its own manufacture from 1980 to 1990. It is one of the three major components for proper engine operation: the computer, electrically controlled carburetor, and the oxygen sensor in the exhaust system.

A backfire or afterburn is combustion or an explosion produced by a running internal combustion engine that occurs in the exhaust system, rather than inside the combustion chamber. It is also sometimes referred to as an afterfire, especially in cases where the word backfire is used to mean a fuel burn that occurs while an intake valve is open, causing the fire to move backward through the system and out through the intake instead of the exhaust. When the flame moves backward it may also be called a "pop-back". A backfire can be caused either by ignition that happens with an exhaust valve open or unburnt fuel making its way into the hot exhaust system. A visible flame may momentarily shoot out of the exhaust pipe. A backfire is often a sign that the engine is improperly tuned.

A nitro engine generally refers to an engine powered with a fuel that contains some portion of nitromethane mixed with methanol. Nitromethane is a highly combustible substance that is generally only used in very specifically designed engines found in Top Fuel drag racing and in miniature internal combustion engines in radio control, control line and free flight model aircraft.

Weber Carburetors is an automotive manufacturing company founded in 1923, known for their carburetors.

A throttle is a mechanism by which fluid flow is managed by constriction or obstruction.

A pressure carburetor is a type of fuel metering system manufactured by the Bendix Corporation for piston aircraft engines, starting in the 1940s. It is recognized as an early type of throttle-body fuel injection and was developed to prevent fuel starvation during inverted flight.

The SU carburettor was a constant-depression carburettor made by a British manufacturer of that name or its licensees in various designs spanning most of the twentieth century.

A small engine is the general term for a wide range of small-displacement, low-powered internal combustion engines used to power lawn mowers, generators, concrete mixers and many other machines that require independent power sources. These engines often have simple designs, for example an air-cooled single-cylinder petrol engine with a pull-cord starter, capacitor discharge ignition and a gravity-fed carburettor.

Of the three types of carburetors used on large, high-performance aircraft engines manufactured in the United States during World War II, the Bendix-Stromberg pressure carburetor was the one most commonly found. The other two carburetor types were manufactured by Chandler Groves and Chandler Evans Control Systems (CECO). Both of these types of carburetors had a relatively large number of internal parts, and in the case of the Holley Carburetor, there were complications in its "variable venturi" design.

The Briggs & Stratton Vanguard Big Block V-Twin is a series of American piston engines, designed and produced by Briggs & Stratton of Wauwatosa, Wisconsin for use in commercial applications. They have also been adapted for use as ultralight aircraft engines.

The Ford Model A engine -- primarily developed for the popular Ford Model A automobile -- was one of the most mass-produced automobile engines of the 1920s and 1930s, widely used in automobiles, trucks, tractors and a wide variety of other vehicles and machinery.