Nitrox refers to any gas mixture composed of nitrogen and oxygen. This includes atmospheric air, which is approximately 78% nitrogen, 21% oxygen, and 1% other gases, primarily argon. In the usual application, underwater diving, nitrox is normally distinguished from air and handled differently. The most common use of nitrox mixtures containing oxygen in higher proportions than atmospheric air is in scuba diving, where the reduced partial pressure of nitrogen is advantageous in reducing nitrogen uptake in the body's tissues, thereby extending the practicable underwater dive time by reducing the decompression requirement, or reducing the risk of decompression sickness.

A scuba set, originally just scuba, is any breathing apparatus that is entirely carried by an underwater diver and provides the diver with breathing gas at the ambient pressure. Scuba is an anacronym for self-contained underwater breathing apparatus. Although strictly speaking the scuba set is only the diving equipment that is required for providing breathing gas to the diver, general usage includes the harness by which it is carried, and those accessories which are integral parts of the harness and breathing apparatus assembly, such as a jacket or wing style buoyancy compensator and instruments mounted in a combined housing with the pressure gauge, and in the looser sense, it has been used to refer to all the diving equipment used by the scuba diver, though this would more commonly and accurately be termed scuba equipment or scuba gear. Scuba is overwhelmingly the most common underwater breathing system used by recreational divers and is also used in professional diving when it provides advantages, usually of mobility and range, over surface supplied diving systems, and is allowed by the relevant legislation and code of practice.

Trimix is a breathing gas consisting of oxygen, helium and nitrogen and is used in deep commercial diving, during the deep phase of dives carried out using technical diving techniques, and in advanced recreational diving.

A rebreather is a breathing apparatus that absorbs the carbon dioxide of a user's exhaled breath to permit the rebreathing (recycling) of the substantially unused oxygen content, and unused inert content when present, of each breath. Oxygen is added to replenish the amount metabolised by the user. This differs from open-circuit breathing apparatus, where the exhaled gas is discharged directly into the environment. The purpose is to extend the breathing endurance of a limited gas supply, and, for covert military use by frogmen or observation of underwater life, eliminating the bubbles produced by an open circuit system and in turn not scaring wildlife being filmed. A rebreather is generally understood to be a portable unit carried by the user. The same technology on a vehicle or non-mobile installation is more likely to be referred to as a life-support system.

A diving regulator is a pressure regulator that controls the pressure of breathing gas for diving. The most commonly recognised application is to reduce pressurized breathing gas to ambient pressure and deliver it to the diver, but there are also other types of gas pressure regulator used for diving applications. The gas may be air or one of a variety of specially blended breathing gases. The gas may be supplied from a scuba cylinder carried by the diver or via a hose from a compressor or high-pressure storage cylinders at the surface in surface-supplied diving. A gas pressure regulator has one or more valves in series which reduce pressure from the source, and use the downstream pressure as feedback to control the delivered pressure, or the upstream pressure as feedback to prevent excessive flow rates, lowering the pressure at each stage.

The Soviet, later Russian IDA71 military and naval rebreather is an oxygen rebreather intended for use by naval and military divers including Russian commando frogmen. As supplied it is in a plain backpack harness with no buoyancy aid. The casing is pressed aluminium with a hinged cover. It has a small optional nitrox cylinder which can be clipped on its outside to convert it to nitrox mode. It contains one oxygen cylinder and two absorbent canisters. In the bottom of its casing is an empty space which is intended for an underwater communications set.

Scuba diving is a mode of underwater diving whereby divers use breathing equipment that is completely independent of a surface air supply. The name "scuba", an acronym for "Self-Contained Underwater Breathing Apparatus", was coined by Christian J. Lambertsen in a patent submitted in 1952. Scuba divers carry their own source of breathing gas, usually compressed air, affording them greater independence and movement than surface-supplied divers, and more time underwater than free divers. Although the use of compressed air is common, a gas blend with a higher oxygen content, known as enriched air or nitrox, has become popular due to the reduced nitrogen intake during long and/or repetitive dives. Also, breathing gas diluted with helium may be used to reduce the likelihood and effects of nitrogen narcosis during deeper dives.

Dräger is a German company based in Lübeck which makes breathing and protection equipment, gas detection and analysis systems, and noninvasive patient monitoring technologies. Customers include hospitals, fire departments and diving companies.

The breathing performance of regulators is a measure of the ability of a breathing gas regulator to meet the demands placed on it at varying ambient pressures and temperatures, and under varying breathing loads, for the range of breathing gases it may be expected to deliver. Performance is an important factor in design and selection of breathing regulators for any application, but particularly for underwater diving, as the range of ambient operating pressures and temperatures, and variety of breathing gases is broader in this application. A diving regulator is a device that reduces the high pressure in a diving cylinder or surface supply hose to the same pressure as the diver's surroundings. It is desirable that breathing from a regulator requires low effort even when supplying large amounts of breathing gas as this is commonly the limiting factor for underwater exertion, and can be critical during diving emergencies. It is also preferable that the gas is delivered smoothly without any sudden changes in resistance while inhaling or exhaling, and that the regulator does not lock up and either fail to supply gas or free-flow. Although these factors may be judged subjectively, it is convenient to have standards by which the many different types and manufactures of regulators may be objectively compared.

A bailout bottle (BoB) or, more formally, bailout cylinder is a scuba cylinder carried by an underwater diver for use as an emergency supply of breathing gas in the event of a primary gas supply failure. A bailout cylinder may be carried by a scuba diver in addition to the primary scuba set, or by a surface supplied diver using either free-flow or demand systems. The bailout gas is not intended for use during the dive except in an emergency, and would be considered a fully redundant breathing gas supply if used correctly. The term may refer to just the cylinder, or the bailout set or emergency gas supply (EGS), which is the cylinder with the gas delivery system attached. The bailout set or bailout system is the combination of the emergency gas cylinder with the gas delivery system to the diver, which includes a diving regulator with either a demand valve, a bailout block, or a bailout valve (BOV).

Scuba gas management is the aspect of scuba diving which includes the gas planning, blending, filling, analysing, marking, storage, and transportation of gas cylinders for a dive, the monitoring and switching of breathing gases during a dive, efficient and correct use of the gas, and the provision of emergency gas to another member of the dive team. The primary aim is to ensure that everyone has enough to breathe of a gas suitable for the current depth at all times, and is aware of the gas mixture in use and its effect on decompression obligations, nitrogen narcosis, and oxygen toxicity risk. Some of these functions may be delegated to others, such as the filling of cylinders, or transportation to the dive site, but others are the direct responsibility of the diver using the gas.

Rebreather diving is underwater diving using diving rebreathers, a class of underwater breathing apparatus which recirculate the breathing gas exhaled by the diver after replacing the oxygen used and removing the carbon dioxide metabolic product. Rebreather diving is practiced by recreational, military and scientific divers in applications where it has advantages over open circuit scuba, and surface supply of breathing gas is impracticable. The main advantages of rebreather diving are extended gas endurance, low noise levels, and lack of bubbles.

The Halcyon Passive, Variable Ratio-Biased Addition Semi-Closed rebreather is a unique design of semi-closed rebreather using a depth-compensated passive gas addition system. Passive addition implies that in steady state operation addition of fresh feed gas is a response to low volume of gas in the loop - the gas is injected when the top of the counterlung activates a demand type addition valve, which provides feed gas as long as the diver continues to inhale. The mechanism discharges gas to the environment in proportion to breathing volume to induce this gas feed.

The Halcyon RB80 is a non-depth-compensated passive addition semi-closed circuit rebreather of similar external dimensions to a standard AL80 scuba cylinder. It was originally developed by Reinhard Buchaly (RB) in 1996 for the cave exploration dives conducted by the European Karst Plain Project (EKPP).

Work of breathing (WOB) is the energy expended to inhale and exhale a breathing gas. It is usually expressed as work per unit volume, for example, joules/litre, or as a work rate (power), such as joules/min or equivalent units, as it is not particularly useful without a reference to volume or time. It can be calculated in terms of the pulmonary pressure multiplied by the change in pulmonary volume, or in terms of the oxygen consumption attributable to breathing.

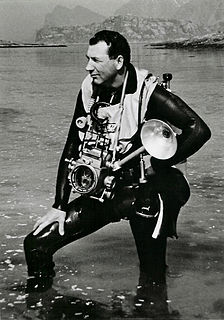

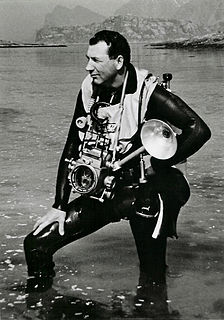

The history of scuba diving is closely linked with the history of the equipment. By the turn of the twentieth century, two basic architectures for underwater breathing apparatus had been pioneered; open-circuit surface supplied equipment where the diver's exhaled gas is vented directly into the water, and closed-circuit breathing apparatus where the diver's carbon dioxide is filtered from the exhaled breathing gas, which is then recirculated, and more gas added to replenish the oxygen content. Closed circuit equipment was more easily adapted to scuba in the absence of reliable, portable, and economical high pressure gas storage vessels. By the mid-twentieth century, high pressure cylinders were available and two systems for scuba had emerged: open-circuit scuba where the diver's exhaled breath is vented directly into the water, and closed-circuit scuba where the carbon dioxide is removed from the diver's exhaled breath which has oxygen added and is recirculated. Oxygen rebreathers are severely depth limited due to oxygen toxicity risk, which increases with depth, and the available systems for mixed gas rebreathers were fairly bulky and designed for use with diving helmets. The first commercially practical scuba rebreather was designed and built by the diving engineer Henry Fleuss in 1878, while working for Siebe Gorman in London. His self contained breathing apparatus consisted of a rubber mask connected to a breathing bag, with an estimated 50–60% oxygen supplied from a copper tank and carbon dioxide scrubbed by passing it through a bundle of rope yarn soaked in a solution of caustic potash. During the 1930s and all through World War II, the British, Italians and Germans developed and extensively used oxygen rebreathers to equip the first frogmen. In the U.S. Major Christian J. Lambertsen invented a free-swimming oxygen rebreather. In 1952 he patented a modification of his apparatus, this time named SCUBA, an acronym for "self-contained underwater breathing apparatus," which became the generic English word for autonomous breathing equipment for diving, and later for the activity using the equipment. After World War II, military frogmen continued to use rebreathers since they do not make bubbles which would give away the presence of the divers. The high percentage of oxygen used by these early rebreather systems limited the depth at which they could be used due to the risk of convulsions caused by acute oxygen toxicity.

The following index is provided as an overview of and topical guide to underwater diving:

A Diving rebreather is an underwater breathing apparatus that absorbs the carbon dioxide of a diver's exhaled breath to permit the rebreathing (recycling) of the substantially unused oxygen content, and unused inert content when present, of each breath. Oxygen is added to replenish the amount metabolised by the diver. This differs from open-circuit breathing apparatus, where the exhaled gas is discharged directly into the environment. The purpose is to extend the breathing endurance of a limited gas supply, and, for covert military use by frogmen or observation of underwater life, to eliminate the bubbles produced by an open circuit system. A diving rebreather is generally understood to be a portable unit carried by the user, and is therefore a type of self-contained underwater breathing apparatus (scuba). A semi-closed rebreather carried by the diver may also be known as a gas extender. The same technology on a submersible or surface installation is more likely to be referred to as a life-support system.