| |

| Identifiers | |

|---|---|

3D model (JSmol) | |

| ChEBI | |

| ChEMBL | |

| ChemSpider | |

| ECHA InfoCard | 100.005.054 |

| EC Number |

|

PubChem CID | |

| UNII | |

CompTox Dashboard (EPA) | |

| |

| |

| Properties | |

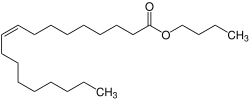

| C22H42O2 | |

| Molar mass | 338.576 g·mol−1 |

| Hazards | |

| GHS labelling: [1] | |

| |

| Warning | |

| H315, H319, H335 | |

| P261, P264, P264+P265, P271, P280, P302+P352, P304+P340, P305+P351+P338, P319, P321, P332+P317, P337+P317, P362+P364, P403+P233, P405, P501 | |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

Butyl oleate is a fatty acid ester and an organic chemical found in liquid form. It has the formula C22H42O2 and the CAS Registry Number 142-77-8. [2] It is REACH registered and produced or imported into the European Union with the EC number of 205-559-6.