A minicomputer, or colloquially mini, is a type of smaller general-purpose computer developed in the mid-1960s and sold at a much lower price than mainframe and mid-size computers from IBM and its direct competitors. In a 1970 survey, The New York Times suggested a consensus definition of a minicomputer as a machine costing less than US$25,000, with an input-output device such as a teleprinter and at least four thousand words of memory, that is capable of running programs in a higher level language, such as Fortran or BASIC.

In electronics and photonics design, tape-out or tapeout is the final stage of the design process for integrated circuits or printed circuit boards before they are sent for manufacturing. The tapeout is specifically the point at which the graphic for the photomask of the circuit is sent to the fabrication facility.

Computer-aided design (CAD) is the use of computers to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. Designs made through CAD software help protect products and inventions when used in patent applications. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The terms computer-aided drafting (CAD) and computer-aided design and drafting (CADD) are also used.

Wang Laboratories was a US computer company founded in 1951 by An Wang and G. Y. Chu. The company was successively headquartered in Cambridge, Massachusetts (1954–1963), Tewksbury, Massachusetts (1963–1976), and finally in Lowell, Massachusetts (1976–1997). At its peak in the 1980s, Wang Laboratories had annual revenues of US$3 billion and employed over 33,000 people. It was one of the leading companies during the time of the Massachusetts Miracle.

Electronic design automation (EDA), also referred to as electronic computer-aided design (ECAD), is a category of software tools for designing electronic systems such as integrated circuits and printed circuit boards. The tools work together in a design flow that chip designers use to design and analyze entire semiconductor chips. Since a modern semiconductor chip can have billions of components, EDA tools are essential for their design; this article in particular describes EDA specifically with respect to integrated circuits (ICs).

The history of computing hardware starting at 1960 is marked by the conversion from vacuum tube to solid-state devices such as transistors and then integrated circuit (IC) chips. Around 1953 to 1959, discrete transistors started being considered sufficiently reliable and economical that they made further vacuum tube computers uncompetitive. Metal–oxide–semiconductor (MOS) large-scale integration (LSI) technology subsequently led to the development of semiconductor memory in the mid-to-late 1960s and then the microprocessor in the early 1970s. This led to primary computer memory moving away from magnetic-core memory devices to solid-state static and dynamic semiconductor memory, which greatly reduced the cost, size, and power consumption of computers. These advances led to the miniaturized personal computer (PC) in the 1970s, starting with home computers and desktop computers, followed by laptops and then mobile computers over the next several decades.

Programmable Array Logic (PAL) is a family of programmable logic device semiconductors used to implement logic functions in digital circuits that was introduced by Monolithic Memories, Inc. (MMI) in March 1978. MMI obtained a registered trademark on the term PAL for use in "Programmable Semiconductor Logic Circuits". The trademark is currently held by Lattice Semiconductor.

A gate array is an approach to the design and manufacture of application-specific integrated circuits (ASICs) using a prefabricated chip with components that are later interconnected into logic devices according to custom order by adding metal interconnect layers in the factory. It was popular during the upheaval in the semiconductor industry in the 1980s, and its usage declined by the end of the 1990s.

In integrated circuit design, integrated circuit (IC) layout, also known IC mask layout or mask design, is the representation of an integrated circuit in terms of planar geometric shapes which correspond to the patterns of metal, oxide, or semiconductor layers that make up the components of the integrated circuit. Originally the overall process was called tapeout, as historically early ICs used graphical black crepe tape on mylar media for photo imaging.

Computervision, Inc. (CV) was an early pioneer in Computer Aided Design and Manufacturing (CAD/CAM). Computervision was founded in 1969 by Marty Allen and Philippe Villers, and headquartered in Bedford, Massachusetts, United States. Its early products were built on a Data General Nova platform. Starting around 1975, Computervision built its own "CGP" Nova-compatible 16-bit computers with added instructions optimized for graphics applications and using its own operating system known as Computervision Graphic Operating System (CGOS). In the 1980s, Computervision rewrote their code to operate on Unix-based platforms.

Prime Computer, Inc. was a Natick, Massachusetts-based producer of minicomputers from 1972 until 1992. With the advent of PCs and the decline of the minicomputer industry, Prime was forced out of the market in the early 1990s, and by the end of 2010 the trademarks for both PRIME and PRIMOS no longer existed

GDSII stream format (GDSII), is a binary database file format which is the de facto industry standard for Electronic Design Automation data exchange of integrated circuit or IC layout artwork. It is a binary file format representing planar geometric shapes, text labels, and other information about the layout in hierarchical form. The data can be used to reconstruct all or part of the artwork to be used in sharing layouts, transferring artwork between different tools, or creating photomasks.

Place and route is a stage in the design of printed circuit boards, integrated circuits, and field-programmable gate arrays. As implied by the name, it is composed of two steps, placement and routing. The first step, placement, involves deciding where to place all electronic components, circuitry, and logic elements in a generally limited amount of space. This is followed by routing, which decides the exact design of all the wires needed to connect the placed components. This step must implement all the desired connections while following the rules and limitations of the manufacturing process.

In electronic design automation, a design rule is a geometric constraint imposed on circuit board, semiconductor device, and integrated circuit (IC) designers to ensure their designs function properly, reliably, and can be produced with acceptable yield. Design rules for production are developed by process engineers based on the capability of their processes to realize design intent. Electronic design automation is used extensively to ensure that designers do not violate design rules; a process called design rule checking (DRC). DRC is a major step during physical verification signoff on the design, which also involves LVS checks, XOR checks, ERC, and antenna checks. The importance of design rules and DRC is greatest for ICs, which have micro- or nano-scale geometries; for advanced processes, some fabs also insist upon the use of more restricted rules to improve yield.

OrCAD Systems Corporation was a software company that made OrCAD, a proprietary software tool suite used primarily for electronic design automation (EDA). The software is used mainly by electronic design engineers and electronic technicians to create electronic schematics, and perform mixed-signal simulation and electronic prints for manufacturing printed circuit boards (PCBs). OrCAD was taken over by Cadence Design Systems in 1999 and was integrated with Cadence Allegro in 2005.

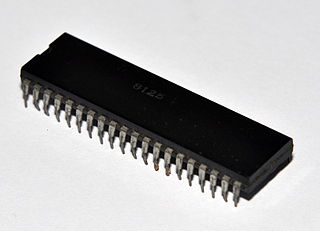

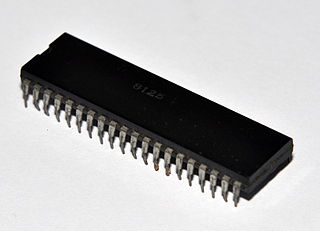

Integrated circuit design, semiconductor design, chip design or IC design, is a sub-field of electronics engineering, encompassing the particular logic and circuit design techniques required to design integrated circuits, or ICs. ICs consist of miniaturized electronic components built into an electrical network on a monolithic semiconductor substrate by photolithography.

An integrated circuit layout editor or IC layout editor is an electronic design automation software tool that allows a user to digitize the shapes and patterns that form an integrated circuit. Typically the view will include the components, metal routing tracks, vias and electrical pins. Software of this type is similar to computer aided drafting software, but is specialized for the task of integrated circuit layout. The typical flow for the layout of analog circuits might be :

ECAD, Inc., based in Santa Clara, California, was an early vendor of electronic design automation software. The company was best known for its design rule checking product Dracula, but also produced IC layout and PC layout software. Eventually, in a merger with SDA, it became Cadence Design Systems.

MEDUSA, is a CAD program used in the areas of mechanical and plant engineering by manufacturers and Engineering, Procurement and Construction (EPC) companies. The system's history is closely tied to the beginnings of mainstream CAD and the research culture fostered by Cambridge University and the UK government as well as the resulting transformation of Cambridge into a world-class tech centre in the 1980s.