A gunnies, gunnis, or gunniss is the space left in a mine after the extraction by stoping of a vertical or near vertical ore-bearing lode. The term is also used when this space breaks the surface of the ground, but it can then be known as a coffin or goffen. It can also be used to describe the deep trenches that were dug by early miners in following the ore-bearing lode downwards from the surface – in this case they are often called open-works; their existence can provide the earliest evidence of mining in an area. William Pryce, writing in 1778, also used the term as a measure of width, a single gunnies being equal to three feet.

Camborne is a town in Cornwall, England. The population at the 2011 Census was 20,845. The northern edge of the parish includes a section of the South West Coast Path, Hell's Mouth and Deadman's Cove.

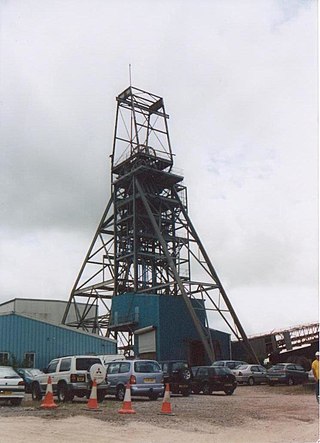

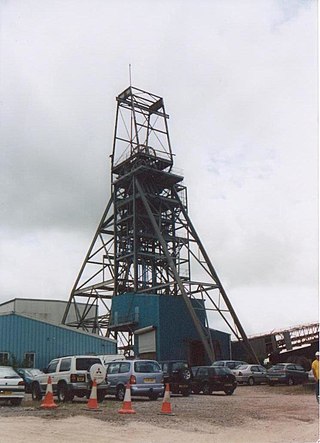

Geevor Tin Mine, formerly North Levant Mine is a tin mine in the far west of Cornwall, England, between the villages of Pendeen and Trewellard. It was operational between 1911 and 1990 during which time it produced about 50,000 tons of black tin. It is now a museum and heritage centre left as a living history of a working tin mine. The museum is an Anchor Point of ERIH, The European Route of Industrial Heritage. Since 2006, the mine has been part of the UNESCO World Heritage Site Cornwall and West Devon Mining Landscape.

The Botallack Mine is a former mine in Botallack in the west of Cornwall, UK. Since 2006 it has been part of the UNESCO World Heritage Site – Cornwall and West Devon Mining Landscape. The mine is within the Aire Point to Carrick Du Site of Special Scientific Interest (SSSI) and the South West Coast Path passes along the cliff.

The King Edward Mine at Camborne, Cornwall, in the United Kingdom is a mine wholly owned by Cornwall Council.

Mining in Cornwall and Devon, in the southwest of Britain, is thought to have begun in the early-middle Bronze Age with the exploitation of cassiterite. Tin, and later copper, were the most commonly extracted metals. Some tin mining continued long after the mining of other metals had become unprofitable, but ended in the late 20th century. In 2021, it was announced that a new mine was extracting battery-grade lithium carbonate, more than 20 years after the closure of the last South Crofty tin mine in Cornwall in 1998.

Gwennap is a village and civil parish in Cornwall, England, United Kingdom. It is about five miles (8 km) southeast of Redruth. Hamlets of Burncoose, Comford, Coombe, Crofthandy, Cusgarne, Fernsplatt, Frogpool, Hick's Mill, Tresamble and United Downs lie in the parish, as does Little Beside country house.

The Cornwall and West Devon Mining Landscape is a World Heritage Site which includes select mining landscapes in Cornwall and West Devon in the south west of England. The site was added to the World Heritage List during the 30th Session of the UNESCO World Heritage Committee in Vilnius, July 2006. Following plans in 2011 to restart mining at South Crofty, and to build a supermarket at Hayle Harbour, the World Heritage Committee drafted a decision in 2014 to put the site on the List of World Heritage in Danger, but this was rejected at the 38th Committee Session at Doha, Qatar, in favour of a follow-up Reactive Monitoring Mission.

Pool is a village in Carn Brea civil parish in west Cornwall, England. It is bypassed by the A30, on the A3047 between Camborne and Redruth, between Tuckingmill and Illogan Highway.

Tuckingmill is a village in Cornwall, England, United Kingdom, which is in the civil parish of Camborne. Tucking Mill was the Cornish term for a fulling mill which was where homespun cloth was dipped, cleansed and dressed. There is a mention of a fulling mill in this region as early as 1250. The ecclesiastical parish of Tuckingmill was constituted in 1845, being carved out of a western section of the parish of Illogan and an eastern section of Camborne parish. It covers 1,300 acres (5.3 km2).

South Crofty is a metalliferous tin and copper mine located in the village of Pool, Cornwall, England. An ancient mine, it has seen production for over 400 years, and extends almost two and a half miles across and 3,000 feet (910 m) down and has mined over 40 lodes. Evidence of mining activity in South Crofty has been dated back to 1592, with full-scale mining beginning in the mid-17th century. The mine went into serious decline after 1985 and eventually closed in 1998. After several changes of ownership, South Crofty is owned by Cornish Metals Inc, which is working to re-open the mine, as of November 2022, having received a permit for dewatering the mine.

Holman Brothers Ltd. was an English mining equipment manufacturer founded in 1801 based in Camborne.

A bal maiden, from the Cornish language bal, a mine, and the English "maiden", a young or unmarried woman, was a female manual labourer working in the mining industries of Cornwall and western Devon, at the south-western extremity of Great Britain. The term has been in use since at least the early 18th century. At least 55,000 women and girls worked as bal maidens, and the actual number is likely to have been much higher.

Wheal Vor was a metalliferous mine about 2 miles (3.2 km) north west of Helston and 1 mile (1.6 km) north of the village of Breage in the west of Cornwall, England, UK. It is considered to be part of the Mount's Bay mining district. Until the mid-19th century the mine was known for its willingness to try out new innovations. Although very rich in copper and tin ores, the mine never lived up to its expectations. During the later part of the 19th century it had several periods of closure, with an attempt to reopen it in the 1960s which was not successful mainly because of bureaucracy. Today the site is part of the Cornwall and West Devon Mining Landscape.

East Pool mine, was a metalliferous mine in the Camborne and Redruth mining area, just east of the village of Pool in Cornwall. Worked from the early 18th century until 1945, first for copper and later tin, it was very profitable for much of its life. Today the site has two preserved beam engines and is part of the Cornwall and West Devon Mining Landscape World Heritage Site. It is owned by the National Trust.

Consolidated Mines, also known as Great Consolidated mine, but most commonly called Consols or Great Consols was a metalliferous mine about a mile ESE of the village of St Day, Cornwall, England. Mainly active during the first half of the 19th century, its mining sett was about 600 yards north–south; and 2,700 yards east–west, to the east of Carharrack. Although always much troubled by underground water, the mine was at times highly profitable, and it was the largest single producer of copper ore in Cornwall. Today the mine is part of the Cornwall and West Devon Mining Landscape World Heritage Site.

The Ding Dong mines lie in an old and extensive mining area in the parish of Madron, in Penwith, Cornwall. They are about two miles north east of the St Just to Penzance road and look over Mount's Bay and St Michael's Mount to the south west. Since 2006 the site has been a UNESCO World Heritage Site, part of Cornwall and West Devon Mining Landscape.

The Trevithick Society is a registered charity named for Richard Trevithick, a Cornish engineer who contributed to the use of high pressure steam engines for transportation and mining applications.

South Wheal Frances is a former mine accessing the copper and tin of the Great Flat Lode south of Camborne in Cornwall, England.

Basset Mines was a mining company formed in Cornwall, England, by the amalgamation of six copper and tin mining setts. It operated from 1896 until 1918, when it was closed due to a fall in the price of tin.