Related Research Articles

A V12 engine is a twelve-cylinder piston engine where two banks of six cylinders are arranged in a V configuration around a common crankshaft. V12 engines are more common than V10 engines. However, they are less common than V8 engines.

A V16 engine is a sixteen-cylinder piston engine where two banks of eight cylinders are arranged in a V configuration around a common crankshaft. V16 engines are less common than engines with fewer cylinders, such as V8 and V12 engines. Each bank of a V16 engine can be thought of as a straight-8, a design that can be inherently balanced. Most V16 engines have a 45° bank angle.

The Napier Deltic engine is a British opposed-piston valveless, supercharged uniflow scavenged, two-stroke diesel engine used in marine and locomotive applications, designed and produced by D. Napier & Son. Unusually, the cylinders were disposed in a three-bank triangle, with a crankshaft at each corner of the triangle.

11001 was one of the first British Railways diesel locomotives, built in 1949 at British Railways' Ashford railway works. It was designed by Oliver Bulleid when he was Chief Mechanical Engineer of the Southern Railway. It was powered by a Paxman RPH Series 1 engine, capable of delivering 500 brake horsepower (370 kW) at 1,250 rpm. It was driven via a Vulcan-Sinclair fluid coupling to an SSS (synchro-self-shifting) Powerflow gearbox. The gearbox provided three forward and reverse gears in either high or low range, with top speed ranging from 5 mph (8 km/h) in 1st gear, low range up to 36 mph (58 km/h). It had a 0-6-0 wheel formation, driven by rods from a rear jackshaft on the final drive, and with Bulleid's favoured BFB wheels.

Paxman was a major British brand of diesel engines. Ownership has changed on a number of occasions since the company's formation in 1865, and the brand is now part of MAN Energy Solutions. At its peak, the Paxman works covered 23 acres (9.3 ha) and employed over 2,000 people. Early Paxman diesel engines carried the name Paxman Ricardo.

The British Rail Class 29 were a class of 20 diesel-electric Bo-Bo locomotives produced by the re-engining of the NBL Type 2 units. The units were designed for both passenger and freight trains.

British Railways 10100 was an unusual experimental diesel locomotive known informally as The Fell Diesel Locomotive. It was the joint production of Davey Paxman & Co, Shell Refining & Marketing Co and Lt-Col L. F. R. Fell, built for them by the London, Midland and Scottish Railway at Derby. Sir Harry Ricardo was also involved. By the time it emerged in 1950, nationalisation had taken place and it carried British Railways livery. The locomotive had six diesel engines, four of them used for traction. There were two auxiliary engines, both of which were 150 hp (110 kW) AEC 6-cylinder units, and these drove the pressure-chargers for the main engines and the purpose of this arrangement was to enable the main engines to deliver very high torque at low crankshaft speed.

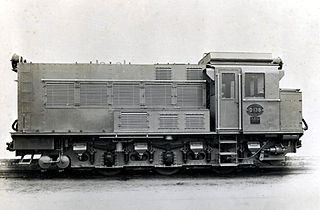

British Railways 10800 was a diesel locomotive built by the North British Locomotive Company for British Railways in 1950. It had been ordered by the London, Midland and Scottish Railway in 1946 but did not appear until after the 1948 nationalisation of the railways.

Rhodesia Railways class DE2 are a type of diesel locomotive built for operations on Rhodesia Railways in the 1950s. The first entered service on 22 June 1955.

The EMD 710 is a line of diesel engines built by Electro-Motive Diesel. The 710 series replaced the earlier EMD 645 series when the 645F series proved to be unreliable in the early 1980s 50-series locomotives which featured a maximum engine speed of 950 rpm. The EMD 710 is a relatively large medium-speed two-stroke diesel engine that has 710 cubic inches displacement per cylinder, and a maximum engine speed of 900 rpm.

L. Gardner and Sons Ltd was a British builder of diesel engines for stationary, marine, road and rail applications. The company was founded in Hulme, Manchester, England in 1868. It started building engines around 1895. The firm ceased engine production in the mid-1990s.

Blackstone & Co. was a farm implement maker at Stamford, Lincolnshire, United Kingdom.

The Paxman Valenta, also known as Y3J and RP200, is a diesel fuelled internal combustion engine formerly made by Paxman in Colchester, England. It was originally developed for, and previously used in the British Rail (BR) Class 43 diesel-electric locomotives, a pair of which powered the InterCity 125 High Speed Train (HST) in a push-pull train set configuration. The Valenta has also been used for electricity generation in diesel generators on offshore oil rig platforms in British waters.

The Heilmann locomotives were a series of three experimental steam-electric locomotives produced in the 1890s for the French Chemins de fer de l'Ouest. A prototype was built in 1894 and two larger locomotives were built in 1897. These locomotives used electric transmission, much like later-popular diesel-electric locomotives and various other self powered locomotives.

The Kolomna Locomotive Works is a major producer of railway locomotives as well as locomotive and marine diesel engines in Russia. The plant started production in 1869 with a freight steam locomotive, one of the first in Russia. In the Russian Empire, Kolomna was one of the few producers in Russia. During this period, 139 types of steam locomotives were designed. As of 2015, the company is now a part of Transmashholding.

The South African Railways Class DS of 1939 was a diesel-electric locomotive.

The South African Railways Class DS1 of 1939 was a diesel-electric locomotive.

A tunnel crankcase, tunnel crankshaft or disc-webbed crankshaft is a design feature of a piston engine where the main bearings that support the crankshaft within the crankcase form the largest diameter of any part of the crankshaft and are larger than the crank webs. This requires a crankcase with a large tunnel instead of cross web supports for narrower main bearings, hence the name.

The South African Railways gas-electric locomotive of 1923 was an experimental gas-electric locomotive. The fuel, suction gas, was generated on-board the locomotive from coal.

T478.3 is a class of locomotives built for Czechoslovak State Railways to replace the most powerful steam locomotives in heavy passenger and freight service. Their design is based on the type T478.1; the main difference is the new, more powerful V12 diesel engine.

References

- 1 2 3 4 5 6 7 8 9 10 11 Carr, Richard (28 September 2022). "Ventura (also known as the YJ)". PaxmanHistory.org.uk. Richard Carr's Paxman history pages. Retrieved 15 August 2023.

- 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Carr, Richard (29 October 2008). "Paxman Ventura (YJ) diesel engines". PaxmanHistory.org.uk. Richard Carr's Paxman history pages. Retrieved 15 August 2023.

- 1 2 3 4 5 6 7 8 Bolton, William F. (1963). The Railwayman's Diesel Manual (4th ed.). pp. 79–80.

- 1 2 3 4 5 Evans, R.K. (May 1964). "The Ventura – Paxman's high-speed engine". Modern Railways . pp. 328–329.

- 1 2 Diesel Manual (1963), pp. 49–53.

- ↑ Carr, Richard (28 September 2022). "Paxman ZH". PaxmanHistory.org.uk. Richard Carr's Paxman history pages. Retrieved 15 August 2023.

- ↑ "New BR 650hp Type 1 Diesel-Hydraulic Locomotive". Modern Railways . August 1964. pp. 106–107.

- ↑ Marriott, Leo (1986). Type 22. London, England: Ian Allan. ISBN 0-7110-1593-7. OCLC 16806469.

- 1 2 Carr, Richard. "Paxman Rail Traction Diesel Engines". PaxmanHistory.org.uk. Richard Carr's Paxman history pages.