Radiation materials science is a subfield of materials science which studies the interaction of radiation with matter: a broad subject covering many forms of irradiation and of matter.

Radiation materials science is a subfield of materials science which studies the interaction of radiation with matter: a broad subject covering many forms of irradiation and of matter.

Some of the most profound effects of irradiation on materials occur in the core of nuclear power reactors where atoms comprising the structural components are displaced numerous times over the course of their engineering lifetimes. The consequences of radiation to core components includes changes in shape and volume by tens of percent, increases in hardness by factors of five or more, severe reduction in ductility and increased embrittlement, and susceptibility to environmentally induced cracking. For these structures to fulfill their purpose, a firm understanding of the effect of radiation on materials is required in order to account for irradiation effects in design, to mitigate its effect by changing operating conditions, or to serve as a guide for creating new, more radiation-tolerant materials that can better serve their purpose.

The types of radiation that can alter structural materials are neutron radiation, ion beams, electrons (beta particles), and gamma rays. All of these forms of radiation have the capability to displace atoms from their lattice sites, which is the fundamental process that drives the changes in structural metals. The inclusion of ions among the irradiating particles provides a tie-in to other fields and disciplines such as the use of accelerators for the transmutation of nuclear waste, or in the creation of new materials by ion implantation, ion beam mixing, plasma-assisted ion implantation, and ion beam-assisted deposition.

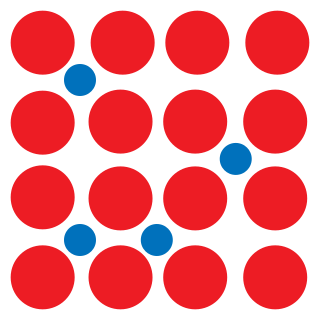

The effect of irradiation on materials is rooted in the initial event in which an energetic projectile strikes a target. While the event is made up of several steps or processes, the primary result is the displacement of an atom from its lattice site. Irradiation displaces an atom from its site, leaving a vacant site behind (a vacancy) and the displaced atom eventually comes to rest in a location that is between lattice sites, becoming an interstitial atom. The vacancy-interstitial pair is central to radiation effects in crystalline solids and is known as a Frenkel pair. The presence of the Frenkel pair and other consequences of irradiation damage determine the physical effects, and with the application of stress, the mechanical effects of irradiation by the occurring of interstitial, phenomena, such as swelling, growth, phase transition, segregation, etc., will be effected. In addition to the atomic displacement, an energetic charged particle moving in a lattice also gives energy to electrons in the system, via the electronic stopping power. This energy transfer can also for high-energy particles produce damage in non-metallic materials, such as ion tracks and fission tracks in minerals. [1] [2]

The radiation damage event is defined as the transfer of energy from an incident projectile to the solid and the resulting distribution of target atoms after completion of the event. This event is composed of several distinct processes:

The result of a radiation damage event is, if the energy given to a lattice atom is above the threshold displacement energy, the creation of a collection of point defects (vacancies and interstitials) and clusters of these defects in the crystal lattice.

The essence of the quantification of radiation damage in solids is the number of displacements per unit volume per unit time :

where is the atom number density, and are the maximum and minimum energies of the incoming particle, is the energy dependent particle flux, and are the maximum and minimum energies transferred in a collision of a particle of energy and a lattice atom, is the cross section for the collision of a particle of energy that results in a transfer of energy to the struck atom, is the number of displacements per primary knock-on atom.

The two key variables in this equation are and . The term describes the transfer of energy from the incoming particle to the first atom it encounters in the target, the primary knock-on atom; The second quantity is the total number of displacements that the primary knock-on atom goes on to make in the solid; Taken together, they describe the total number of displacements caused by an incoming particle of energy , and the above equation accounts for the energy distribution of the incoming particles. The result is the total number of displacements in the target from a flux of particles with a known energy distribution.

In radiation material science the displacement damage in the alloy ( = displacements per atom in the solid ) is a better representation of the effect of irradiation on materials properties than the fluence ( neutron fluence, ).

See also Wigner effect.

To generate materials that fit the increasing demands of nuclear reactors to operate with higher efficiency or for longer lifetimes, materials must be designed with radiation resistance in mind. In particular, Generation IV nuclear reactors operate at higher temperatures and pressures compared to modern pressurized water reactors, which account for a vast amount of western reactors. This leads to increased vulnerability to normal mechanical failure in terms of creep resistance as well as radiation damaging events such as neutron-induced swelling and radiation-induced segregation of phases. By accounting for radiation damage, reactor materials would be able to withstand longer operating lifetimes. This allows reactors to be decommissioned after longer periods of time, improving return on investment of reactors without compromising safety. This is of particular interest in developing commercial viability of advanced and theoretical nuclear reactors, and this goal can be accomplished through engineering resistance to these displacement events.

Face-centered cubic metals such as austenitic steels and Ni-based alloys can benefit greatly from grain boundary engineering. Grain boundary engineering attempts to generate higher amounts of special grain boundaries, characterized by favorable orientations between grains. By increasing populations of low energy boundaries without increasing grain size, fracture mechanics of these face centered cubic metals can be changed to improve mechanical properties given a similar displacements per atom value versus non grain boundary engineered alloys. This method of treatment in particular yields better resistance to stress corrosion cracking and oxidation. [3]

By using advanced methods of material selection, materials can be judged on criteria such as neutron-absorption cross sectional area. Selecting materials with minimum neutron-absorption can heavily minimize the number of displacements per atom that occur over a reactor material's lifetime. This slows the radiation embrittlement process by preventing mobility of atoms in the first place, proactively selecting materials that do not interact with the nuclear radiation as frequently. This can have a huge impact on total damage especially when comparing the materials of modern advanced reactors of zirconium to stainless steel reactor cores, which can differ in absorption cross section by an order of magnitude from more-optimal materials. [4]

Example values for thermal neutron cross section are shown in the table below. [5]

| Element | Thermal neutron cross section (barns) |

|---|---|

| Magnesium | 0.059 |

| Lead | 0.17 |

| Zirconium | 0.18 |

| Aluminum | 0.23 |

| Iron | 2.56 |

| Austenitic Stainless Steel | 3.1 |

| Nickel | 4.5 |

| Titanium | 6.1 |

| Cadmium | 2520 |

For nickel-chromium and iron-chromium alloys, short range order can be designed on the nano-scale (<5 nm) that absorbs the interstitial and vacancy's generated by primary knock-on atom events. This allows materials that mitigate the swelling that normally occurs in the presence of high displacements per atom and keep the overall volume percent change under the ten percent range. This occurs through generating a metastable phase that is in constant, dynamic equilibrium with surrounding material. This metastable phase is characterized by having an enthalpy of mixing that is effectively zero with respect to the main lattice. This allows phase transformation to absorb and disperse the point defects that typically accumulate in more rigid lattices. This extends the life of the alloy through making vacancy and interstitial creation less successful as constant neutron excitement in the form of displacement cascades transform the SRO phase, while the SRO reforms in the bulk solid solution. [6]

A crystallographic defect is an interruption of the regular patterns of arrangement of atoms or molecules in crystalline solids. The positions and orientations of particles, which are repeating at fixed distances determined by the unit cell parameters in crystals, exhibit a periodic crystal structure, but this is usually imperfect. Several types of defects are often characterized: point defects, line defects, planar defects, bulk defects. Topological homotopy establishes a mathematical method of characterization.

Particle radiation is the radiation of energy by means of fast-moving subatomic particles. Particle radiation is referred to as a particle beam if the particles are all moving in the same direction, similar to a light beam.

In physics, radiation is the emission or transmission of energy in the form of waves or particles through space or a material medium. This includes:

Ionizing radiation, including nuclear radiation, consists of subatomic particles or electromagnetic waves that have sufficient energy to ionize atoms or molecules by detaching electrons from them. Some particles can travel up to 99% of the speed of light, and the electromagnetic waves are on the high-energy portion of the electromagnetic spectrum.

Neutron radiation is a form of ionizing radiation that presents as free neutrons. Typical phenomena are nuclear fission or nuclear fusion causing the release of free neutrons, which then react with nuclei of other atoms to form new nuclides—which, in turn, may trigger further neutron radiation. Free neutrons are unstable, decaying into a proton, an electron, plus an electron antineutrino. Free neutrons have a mean lifetime of 887 seconds.

Radiation hardening is the process of making electronic components and circuits resistant to damage or malfunction caused by high levels of ionizing radiation, especially for environments in outer space, around nuclear reactors and particle accelerators, or during nuclear accidents or nuclear warfare.

The Wigner effect, also known as the discomposition effect or Wigner's disease, is the displacement of atoms in a solid caused by neutron radiation.

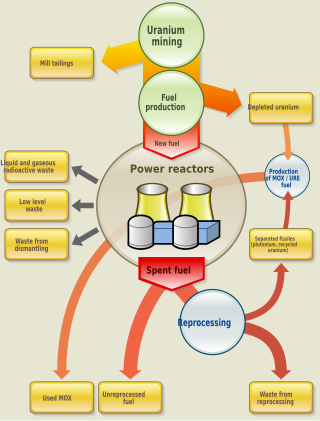

Nuclear fuel refers to any substance, typically fissile material, which is used by nuclear power stations or other nuclear devices to generate energy.

A reactor pressure vessel (RPV) in a nuclear power plant is the pressure vessel containing the nuclear reactor coolant, core shroud, and the reactor core.

In materials science, an interstitial defect is a type of point crystallographic defect where an atom of the same or of a different type, occupies an interstitial site in the crystal structure. When the atom is of the same type as those already present they are known as a self-interstitial defect. Alternatively, small atoms in some crystals may occupy interstitial sites, such as hydrogen in palladium. Interstitials can be produced by bombarding a crystal with elementary particles having energy above the displacement threshold for that crystal, but they may also exist in small concentrations in thermodynamic equilibrium. The presence of interstitial defects can modify the physical and chemical properties of a material.

Radiation damage is the effect of ionizing radiation on physical objects including non-living structural materials. It can be either detrimental or beneficial for materials.

Ion beam mixing is the atomic intermixing and alloying that can occur at the interface separating two different materials during ion irradiation. It is applied as a process for adhering two multilayers, especially a substrate and deposited surface layer. The process involves bombarding layered samples with doses of ion radiation in order to promote mixing at the interface, and generally serves as a means of preparing electrical junctions, especially between non-equilibrium or metastable alloys and intermetallic compounds. Ion implantation equipment can be used to achieve ion beam mixing.

In condensed-matter physics, a collision cascade is a set of nearby adjacent energetic collisions of atoms induced by an energetic particle in a solid or liquid.

In materials science, the threshold displacement energy is the minimum kinetic energy that an atom in a solid needs to be permanently displaced from its site in the lattice to a defect position. It is also known as "displacement threshold energy" or just "displacement energy". In a crystal, a separate threshold displacement energy exists for each crystallographic direction. Then one should distinguish between the minimum and average over all lattice directions' threshold displacement energies. In amorphous solids, it may be possible to define an effective displacement energy to describe some other average quantity of interest. Threshold displacement energies in typical solids are of the order of 10-50 eV.

Stopping and Range of Ions in Matter (SRIM) is a group of computer programs which calculate interactions between ions and matter; the core of SRIM is a program called Transport of Ions in Matter (TRIM). SRIM is popular in the ion implantation research and technology community, and also used widely in other branches of radiation material science.

Plutonium–gallium alloy (Pu–Ga) is an alloy of plutonium and gallium, used in nuclear weapon pits, the component of a nuclear weapon where the fission chain reaction is started. This alloy was developed during the Manhattan Project.

In condensed-matter physics, a primary knock-on atom (PKA) is an atom that is displaced from its lattice site by irradiation; it is, by definition, the first atom that an incident particle encounters in the target. After it is displaced from its initial lattice site, the PKA can induce the subsequent lattice site displacements of other atoms if it possesses sufficient energy, or come to rest in the lattice at an interstitial site if it does not.

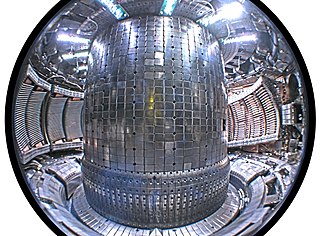

In nuclear fusion power research, the plasma-facing material (PFM) is any material used to construct the plasma-facing components (PFC), those components exposed to the plasma within which nuclear fusion occurs, and particularly the material used for the lining the first wall or divertor region of the reactor vessel.

Neutron embrittlement, sometimes more broadly radiation embrittlement, is the embrittlement of various materials due to the action of neutrons. This is primarily seen in nuclear reactors, where the release of high-energy neutrons causes the long-term degradation of the reactor materials. The embrittlement is caused by the microscopic movement of atoms that are hit by the neutrons; this same action also gives rise to neutron-induced swelling causing materials to grow in size, and the Wigner effect causing energy buildup in certain materials that can lead to sudden releases of energy.

Lattice confinement fusion (LCF) is a type of nuclear fusion in which deuteron-saturated metals are exposed to gamma radiation or ion beams, such as in an IEC fusor, avoiding the confined high-temperature plasmas used in other methods of fusion.