Mount Pleasant Mill is a windmill north of Kirton in Lindsey on the North Cliff Road in North Lincolnshire in the east of England.

Upminster Windmill is a Grade II* listed smock mill located in Upminster in the London Borough of Havering, England. It was formerly known as Abraham's Mill and was in Essex when built. Between 2016 and 2023 the mill was restored to working order and a visitor centre was constructed. The mill and visitor centre are open to the public at selected times.

Durrington or High Salvington Windmill is a Grade II listed post mill in High Salvington, Sussex that has been restored and is in full working order. The mill stands 320 feet (98 m) above sea level and is able to take advantage of incoming sea winds.

New Mill is a Grade II* listed smock mill in Hythe Road, Willesborough, Ashford, Kent. It stands just west of junction 10 of the M20 motorway. It was built in 1869 and is now a museum open to the public.

Stembridge Tower Mill in High Ham, Somerset, England, is the last remaining thatched windmill in England. The mill is a grade II* listed building.

Mostert's Mill is a historic windmill in Mowbray, Cape Town, South Africa. It was built in 1796 and is the oldest surviving complete windmill in South Africa. It was almost completely destroyed by a wildfire on 18 April 2021 but was fully restored by April 2024 and is once more operational and used to grind wheat into whole meal, using the power of the wind. The oldest windmill in South Africa is the De Nieuwe Molen mill in Cape Town, built in 1782.

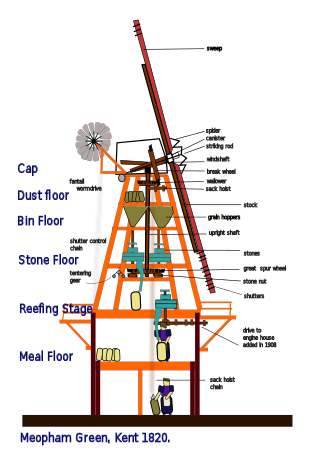

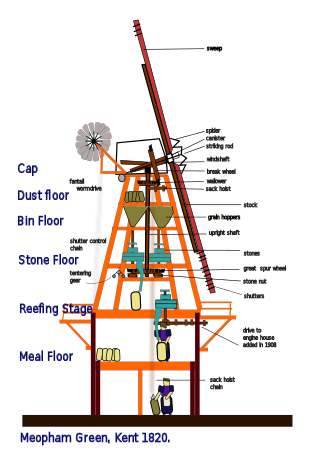

This glossary of mill machinery covers the major pieces of machinery to be found in windmills, watermills and horse mills. It does not cover machinery found in modern factories.

Bocking Windmill or Bocking Churchstreet Windmill is a grade I listed post mill at Bocking, Essex, England which has been restored.

Fryerning Mill is a grade II* listed post mill at Mill Green, Fryerning, Essex, which has been restored.

South Ockendon Windmill was a Smock mill at South Ockendon, Essex, England which collapsed on 2 November 1977.

Debden Windmill is a grade II listed Tower mill at Debden, Essex, England which has been converted to residential use.

Framsden Windmill is a Grade II* listed post mill at Framsden, Suffolk, England which is preserved. The mill was known as Webster's Mill when it was a working mill.

De Zwaluw is a smock mill in Burdaard, Friesland, Netherlands which is working commercially. The mill is listed as a Rijksmonument, number 15585.

De Hoop is a smock mill in Norg, Drenthe, the Netherlands. It was built in 1857 and is listed as a Rijksmonument, number 30781.

Noordenveld is a smock mill in Norg, Drenthe, the Netherlands. It was built in 1878 and is listed as a Rijksmonument, number 30785.

De Zwaluw is a smock mill in Oudemolen, Drenthe, the Netherlands. It was built in 1837 and is listed as a Rijksmonument, number 38148.

The Grafelijke Korenmolen van Zeddam is a tower mill in Zeddam, the Netherlands, which has been restored to working order. The mill may have been built before 1441, making it the oldest windmill in existence in the Netherlands. It is listed as Rijksmonument number 9290.

The Buitenmolen is a tower mill in Zevenaar, Netherlands that was restored to working order in 1970. The mill was built in the beginning of the sixteenth century and is listed as a Rijksmonument, number 40427.

Tot Voordeel en Genoegen is a windmill built in 1798 on the Molendijk 15 in Alphen, Netherlands. It is a large post mill, built above a roundhouse, used for grinding wheat flour. It is the only windmill in the Netherlands that drives three pairs of millstones. The mechanism is mostly wooden, since iron was expensive when it was built. The windmill, which is still functional, can be rotated on its post to face the wind for maximum effect.

Veldkamps Meuln is a 19th-century tower mill in the village of Bellingwolde in the Netherlands.