A clutch is a mechanical device that allows an output shaft to be disconnected from a rotating input shaft. The clutch's input shaft is typically attached to a motor, while the clutch's output shaft is connected to the mechanism that does the work.

Mechanical advantage is a measure of the force amplification achieved by using a tool, mechanical device or machine system. The device trades off input forces against movement to obtain a desired amplification in the output force. The model for this is the law of the lever. Machine components designed to manage forces and movement in this way are called mechanisms. An ideal mechanism transmits power without adding to or subtracting from it. This means the ideal machine does not include a power source, is frictionless, and is constructed from rigid bodies that do not deflect or wear. The performance of a real system relative to this ideal is expressed in terms of efficiency factors that take into account departures from the ideal.

A pulley is a wheel on an axle or shaft enabling a taut cable or belt passing over the wheel to move and change direction, or transfer power between itself and a shaft. A sheave or pulley wheel is a pulley using an axle supported by a frame or shell (block) to guide a cable or exert force.

A gear or gearwheel is a rotating machine part typically used to transmit rotational motion and/or torque by means of a series of teeth that engage with compatible teeth of another gear or other part. The teeth can be integral saliences or cavities machined on the part, or separate pegs inserted into it. In the latter case, the gear is usually called a cogwheel. A cog may be one of those pegs or the whole gear. Two or more meshing gears are called a gear train.

Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic, industrial and agricultural machinery, including conveyors, wire- and tube-drawing machines, printing presses, cars, motorcycles, and bicycles. It consists of a series of short cylindrical rollers held together by side links. It is driven by a toothed wheel called a sprocket. It is a simple, reliable, and efficient means of power transmission.

A continuously variable transmission (CVT) is an automated transmission that can change through a continuous range of gear ratios. This contrasts with other transmissions that provide a limited number of gear ratios in fixed steps. The flexibility of a CVT with suitable control may allow the engine to operate at a constant angular velocity while the vehicle moves at varying speeds.

In a piston engine, either a timing belt or timing chain or set of timing gears is a perishable component used to synchronize the rotation of the crankshaft and the camshaft. This synchronisation ensures that the engine's valves open and close at the correct times in relation to the position of the pistons.

An overhead camshaft (OHC) engine is a piston engine in which the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combustion chamber in the engine block.

A sprocket, sprocket-wheel or chainwheel is a profiled wheel with teeth that mesh with a chain, rack or other perforated or indented material. The name 'sprocket' applies generally to any wheel upon which radial projections engage a chain passing over it. It is distinguished from a gear in that sprockets are never meshed together directly, and differs from a pulley in that sprockets have teeth and pulleys are smooth except for timing pulleys used with toothed belts.

A belt is a loop of flexible material used to link two or more rotating shafts mechanically, most often parallel. Belts may be used as a source of motion, to transmit power efficiently or to track relative movement. Belts are looped over pulleys and may have a twist between the pulleys, and the shafts need not be parallel.

Chain drive is a way of transmitting mechanical power from one place to another. It is often used to convey power to the wheels of a vehicle, particularly bicycles and motorcycles. It is also used in a wide variety of machines besides vehicles.

A gear train or gear set is a machine element of a mechanical system formed by mounting two or more gears on a frame such that the teeth of the gears engage.

A belt-driven bicycle is a chainless bicycle that uses a flexible belt, typically a synchronous toothed design, in order to transmit power from the pedals to the wheel.

The KV6 automotive petrol engine has a 24-valve quad-cam V6 configuration, and a pressurising variable-length intake manifold to add hot spots throughout the rev range. Variants exist in 2.0 to 2.5 litres capacities. These were built initially by Rover Group, then by Powertrain Ltd. KIA manufactured KV6 in Korea under licence. Production moved from the UK to China in 2005, re-designated NV6.

A friction drive or friction engine is a type of transmission that utilises the static friction of two smooth surfaces to transfer torque between two rotating parts.

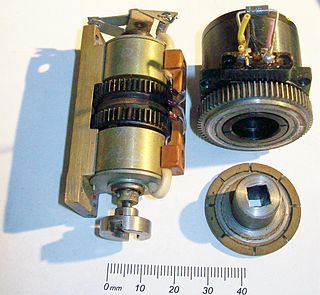

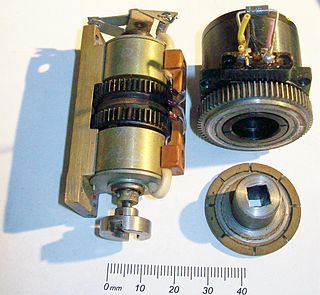

A reduction drive is a mechanical device to shift rotational speed. A planetary reduction drive is a small scale version using ball bearings in an epicyclic arrangement instead of toothed gears.

An idler-wheel is a wheel which serves only to transmit rotation from one shaft to another, in applications where it is undesirable to connect them directly. For example, connecting a motor to the platter of a phonograph, or the crankshaft-to-camshaft gear train of an automobile.

Electromagnetic clutches operate electrically but transmit torque mechanically. This is why they used to be referred to as electro-mechanical clutches. Over the years, EM became known as electromagnetic versus electro-mechanical, referring more about their actuation method versus physical operation. Since the clutches started becoming popular over 60 years ago, the variety of applications and clutch designs has increased dramatically, but the basic operation remains the same today.

Motorcycle components and systems for a motorcycle are engineered, manufactured, and assembled in order to produce motorcycle models with the desired performance, aesthetics, and cost. The key components of modern motorcycles are presented below.

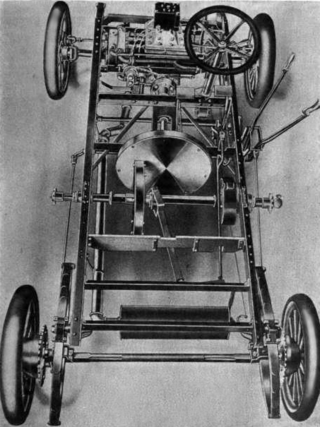

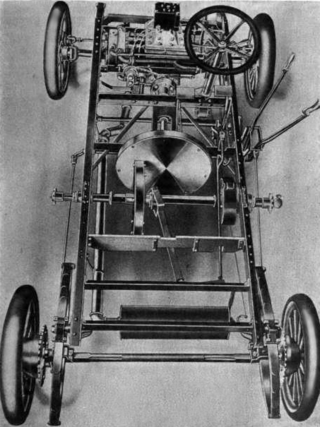

Machine element or hardware refers to an elementary component of a machine. These elements consist of three basic types:

- structural components such as frame members, bearings, axles, splines, fasteners, seals, and lubricants,

- mechanisms that control movement in various ways such as gear trains, belt or chain drives, linkages, cam and follower systems, including brakes and clutches, and

- control components such as buttons, switches, indicators, sensors, actuators and computer controllers.