Production

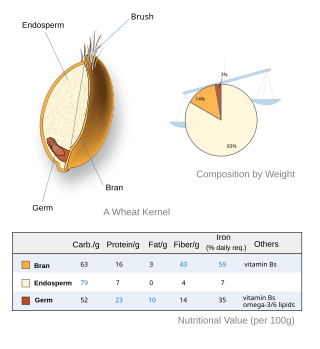

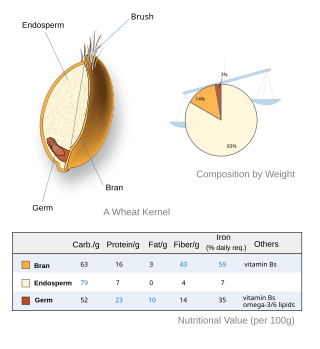

White flour is made entirely from the endosperm or protein/starchy part of the grain, leaving behind the germ and the bran or fiber part. In addition to marketing the bran and germ as products in their own right, middlings include shorts (making up approximately 12% of the original grain, consisting of fractions of endosperm, bran, and germ with an average particle size of 500–900 microns) and red dog (actually a low-grade flour, making up approximately 3% of the original grain, consisting of fractions of endosperm and bran, with an average particle size of 100–300 microns). [3]

The middlings include those portions of the wheat kernel that are richest in proteins, vitamins, lipids and minerals. For example, highly refined patent flour may contain only 10 to 12% of the total thiamine and niacin, 20% of the phosphorus, and 50% of the calcium of the parent grain. [4]

Flour is a powder made by grinding raw grains, roots, beans, nuts, or seeds. Flours are used to make many different foods. Cereal flour, particularly wheat flour, is the main ingredient of bread, which is a staple food for many cultures. Corn flour has been important in Mesoamerican cuisine since ancient times and remains a staple in the Americas. Rye flour is a constituent of bread in both Central Europe and Northern Europe.

Semolina is the name given to coarsely milled durum wheat mainly used in making pasta and sweet puddings. The term semolina is also used to designate coarse millings of other varieties of wheat, and sometimes other grains as well.

Bran, also known as miller's bran, is the component of a cereal grain consisting of the hard layers - the combined aleurone and pericarp - surrounding the endosperm. Corn (maize) bran also includes the pedicel. Along with the germ, it is an integral part of whole grains, and is often produced as a byproduct of milling in the production of refined grains. Bran is highly nutritious, but is difficult to digest due to its high fiber content; its high fat content also reduces its shelf life as the oils/fats are prone to becoming rancid. As such, it is typically removed from whole grain during the refining process - e.g. in processing wheat grain into white flour, or refining brown rice into white rice.

White rice is milled rice that has had its husk, bran, and germ removed. This alters the flavor, texture and appearance of the rice and helps prevent spoilage, extend its storage life, and makes it easier to digest. After milling (hulling), the rice is polished, resulting in a seed with a bright, white, shiny appearance.

Wheat flour is a powder made from the grinding of common wheat used for human consumption. Wheat varieties are called "soft" or "weak" if gluten content is low, and are called "hard" or "strong" if they have high gluten content. Hard flour, or bread flour, is high in gluten, with 12% to 14% gluten content, and its dough has elastic toughness that holds its shape well once baked. Soft flour is comparatively low in gluten and thus results in a loaf with a finer, crumbly texture. Soft flour is usually divided into cake flour, which is the lowest in gluten, and pastry flour, which has slightly more gluten than cake flour.

Enriched flour is flour with specific nutrients added to it. These nutrients include iron and B vitamins. Calcium may also be supplemented. The purpose of enriching flour is to replenish the nutrients in the flour to match the nutritional status of the unrefined product. This differentiates enrichment from fortification, which is the process of introducing new nutrients to a food.

The germ of a cereal grain is the part that develops into a plant; it is the seed embryo. Along with bran, germ is often a by-product of the milling that produces refined grain products. Cereal grains and their components, such as wheat germ oil, rice bran oil, and maize bran, may be used as a source from which vegetable oil is extracted, or used directly as a food ingredient. The germ is retained as an integral part of whole-grain foods. Non-whole grain methods of milling are intended to isolate the endosperm, which is ground into flour, with removal of both the husk (bran) and the germ. Removal of bran produces a flour with a white rather than a brown color and eliminates fiber. The germ is rich in polyunsaturated fats and so germ removal improves the storage qualities of flour.

A whole grain is a grain of any cereal and pseudocereal that contains the endosperm, germ, and bran, in contrast to refined grains, which retain only the endosperm.

Distillers grains are a cereal byproduct of the distillation process. Brewer's spent grain usually refers to barley produced as a byproduct of brewing, while distillers grains are a mix of corn, rice and other grains.

Corn kernels are the fruits of corn. Maize is a grain, and the kernels are used in cooking as a vegetable or a source of starch. The kernel comprise endosperm, germ, pericarp, and tip cap.

Refined grains have been significantly modified from their natural composition, in contrast to whole grains. The modification process generally involves the mechanical removal of bran and germ, either through grinding or selective sifting.

Sprouted bread is a type of bread made from whole grains that have been allowed to sprout. There are a few different types of sprouted grain bread. Some are made with additional added flour; some are made with added gluten; and some, such as Essene bread and Ezekiel bread are made with very few additional ingredients.

A Unifine mill is a single one-pass impact milling system which produces ultrafine-milled whole-grain wheat flour that requires no grain pre-treatment and no screening of the flour. Like the grist or stone mills that had dominated the flour industry for centuries, the bran, germ, and endosperm elements of grain are processed into a nutritious whole wheat flour in one step. Consumers had accepted whole wheat products produced by grist or stone mills. The flour produced by these mills was quite coarse as they included the bran and the germ elements of the grain.

In agriculture, grain quality depends on the use of the grain. In ethanol production, the chemical composition of grain such as starch content is important, in food and feed manufacturing, properties such as protein, oil and sugar are significant, in the milling industry, soundness is the most important factor to consider when it comes to the quality of grain. For grain farmers, high germination percentage and seed dormancy are the main features to consider. For consumers, properties such as color and flavor are most important.

A staple food, food staple, or simply staple, is a food that is eaten often and in such quantities that it constitutes a dominant portion of a standard diet for an individual or a population group, supplying a large fraction of energy needs and generally forming a significant proportion of the intake of other nutrients as well. For humans, a staple food of a specific society may be eaten as often as every day or every meal, and most people live on a diet based on just a small variety of food staples. Specific staples vary from place to place, but typically are inexpensive or readily available foods that supply one or more of the macronutrients and micronutrients needed for survival and health: carbohydrates, proteins, fats, minerals, and vitamins. Typical examples include grains, seeds, nuts and root vegetables. Among them, cereals, legumes and tubers account for about 90% of the world's food calorie intake.

Corn wet-milling is a process of breaking corn kernels into their component parts: corn oil, protein, corn starch, and fiber. It uses water and a series of steps to separate the parts to be used for various products.

Feed manufacturing refers to the process of producing animal feed from raw agricultural products. Fodder produced by manufacturing is formulated to meet specific animal nutrition requirements for different species of animals at different life stages. According to the American Feed Industry Association (AFIA), there are four basic steps:

- Receive raw ingredients: Feed mills receive raw ingredients from suppliers. Upon arrival, the ingredients are weighed, tested and analyzed for various nutrients and to ensure their quality and safety.

- Create a formula: Nutritionists work side by side with scientists to formulate nutritionally sound and balanced diets for livestock, poultry, aquaculture and pets. This is a complex process, as every species has different nutritional requirements.

- Mix ingredients: Once the formula is determined, the mill mixes the ingredients to create a finished product.

- Package and label: Manufacturers determine the best way to ship the product. If it is prepared for retail, it will be "bagged and tagged," or placed into a bag with a label that includes the product's purpose, ingredients and instructions. If the product is prepared for commercial use, it will be shipped in bulk.

Dry milling of grain is mainly utilized to manufacture feedstock into consumer and industrial based products. This process is widely associated with the development of new bio-based associated by-products. The milling process separates the grain into four distinct physical components: the germ, flour, fine grits, and coarse grits. The separated materials are then reduced into food products utilized for human and animal consumption.

The Roller Mill was created by Hungarian bakers in the late 1860s and its popularity spread worldwide throughout the 1900s. Roller mills now produce almost all non-whole grain flour. Enriched flour is flour that meets an FDA standard in the United States. Roller milled white enriched flour makes up over 90% of the flour that comes out of the United States.

Flour extraction is the common process of refining Whole Grain Flour first milled from grain or grist by running it through sifting devices, often called flour dressers.