Quilting is the term given to the process of joining a minimum of three layers of fabric together either through stitching manually using a needle and thread, or mechanically with a sewing machine or specialised longarm quilting system. An array of stitches is passed through all layers of the fabric to create a three-dimensional padded surface. The three layers are typically referred to as the top fabric or quilt top, batting or insulating material, and the backing.

A sewing machine is a machine used to sew fabric and materials together with thread. Sewing machines were invented during the first Industrial Revolution to decrease the amount of manual sewing work performed in clothing companies. Since the invention of the first sewing machine, generally considered to have been the work of Englishman Thomas Saint in 1790, the sewing machine has greatly improved the efficiency and productivity of the clothing industry.

Sewing is the craft of fastening or attaching objects using stitches made with a sewing needle and thread. Sewing is one of the oldest of the textile arts, arising in the Paleolithic era. Before the invention of spinning yarn or weaving fabric, archaeologists believe Stone Age people across Europe and Asia sewed fur and leather clothing using bone, antler or ivory sewing-needles and "thread" made of various animal body parts including sinew, catgut, and veins.

A lockstitch is the most common mechanical stitch made by a sewing machine. The term "single needle stitching", often found on dress shirt labels, refers to lockstitch.

Machine embroidery is an embroidery process whereby a sewing machine or embroidery machine is used to create patterns on textiles. It is used commercially in product branding, corporate advertising, and uniform adornment. It is also used in the fashion industry to decorate garments and apparel. Machine embroidery is used by hobbyists and crafters to decorate gifts, clothing, and home decor. Examples include designs on quilts, pillows, and wall hangings.

A hem in sewing is a garment finishing method, where the edge of a piece of cloth is folded and sewn to prevent unravelling of the fabric and to adjust the length of the piece in garments, such as at the end of the sleeve or the bottom of the garment.

A sewing needle, used for hand-sewing, is a long slender tool with a pointed tip at one end and a hole to hold the sewing thread. The earliest needles were made of bone or wood; modern needles are manufactured from high carbon steel wire and are nickel- or 18K gold-plated for corrosion resistance. High-quality embroidery needles are plated with two-thirds platinum and one-third titanium alloy. Traditionally, needles have been kept in needle books or needlecases which have become objects of adornment. Sewing needles may also be kept in an étui, a small box that held needles and other items such as scissors, pencils and tweezers.

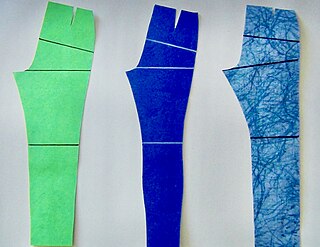

In sewing and fashion design, a pattern is the template from which the parts of a garment are traced onto woven or knitted fabrics before being cut out and assembled. Patterns are usually made of paper, and are sometimes made of sturdier materials like paperboard or cardboard if they need to be more robust to withstand repeated use. The process of making or cutting patterns is sometimes compounded to the one-word Patternmaking, but it can also be written pattern(-)making or pattern cutting.

A buttonhole is a reinforced hole in fabric that a button can pass through, allowing one piece of fabric to be secured to another. The raw edges of a buttonhole are usually finished with stitching. This may be done either by hand or by a sewing machine. Some forms of button, such as a frog, use a loop of cloth or rope instead of a buttonhole.

Knitted fabric is a textile that results from knitting, the process of inter-looping of yarns or inter-meshing of loops. Its properties are distinct from woven fabric in that it is more flexible and can be more readily constructed into smaller pieces, making it ideal for socks and hats.

Christian Dancel was a German-American inventor. He was most notably under contract with the Goodyear Shoe Machinery Company of Connecticut.

Helen Augusta Blanchard was an American inventor who received 28 patents between 1873 and 1915. She was known for her numerous inventions dealing with sewing machines and sewing technology.

A hook-and-eye closure is a simple and secure method of fastening garments together. It consists of a metal hook, commonly wire bent to shape, and an eye of the same material into which the hook fits.

Longarm quilting is the process by which a longarm sewing machine is used to sew together a quilt top, quilt batting and quilt backing into a finished quilt.

Allen Benjamin Wilson (1823–1888) was an American inventor famous for designing, building and patenting some of the first successful sewing machines. He invented both the vibrating and the rotating shuttle designs which, in turns, dominated all home lockstitch sewing machines. With various partners in the 19th century he manufactured reliable sewing machines using the latter shuttle type.

Machine quilting is quilting made using a sewing machine to stitch in rows or patterns using select techniques to stitch through layers of fabric and batting in the manner of old-style hand-quilting. Some machines even replicate hand stitching, for example Sashiko or running stitch quilting.

Sewing is the craft of fastening or attaching objects using stitches made with needle and thread. Sewing is one of the oldest of the textile arts, arising in the Paleolithic Era. Although usually associated with clothing and household linens, sewing is used in a variety of crafts and industries, including shoemaking, upholstery, sailmaking, bookbinding and the manufacturing of some kinds of sporting goods. Sewing is the fundamental process underlying a variety of textile arts and crafts, including embroidery, tapestry, quilting, appliqué and patchwork.

The Singer Model 27 and later model 127 were a series of lockstitch sewing machines produced by the Singer Manufacturing Company from the 1880s to the 1960s.. They were Singer's first sewing machines to make use of "vibrating shuttle" technology. Millions were produced. They are all steel and cast iron, and were built before the advent of planned obsolescence, and so they were designed to be repaired rather than replaced. Consequently many remain today, some in collections and others still in service. In company literature they were called "the woman's faithful friend the world over".

A zigzag stitch is variant geometry of the lockstitch. It is a back-and-forth stitch used where a straight stitch will not suffice, such as in reinforcing buttonholes, in stitching stretchable fabrics, and in temporarily joining two work pieces edge-to-edge.

A presser foot is an attachment used with sewing machines to hold fabric flat as it is fed through the machine and stitched. Sewing machines have feed dogs in the bed of the machine to provide traction and move the fabric as it is fed through the machine, while the sewer provides extra support for the fabric by guiding it with one hand. A presser foot keeps the fabric flat so that it does not rise and fall with the needle and pucker as it is stitched. When especially thick workpieces are to be sewn, such as quilts, a specialized attachment called a walking foot is often used rather than a presser foot.