Crochet is a process of creating textiles by using a crochet hook to interlock loops of yarn, thread, or strands of other materials. The name is derived from the French term crochet, which means 'hook'. Hooks can be made from a variety of materials, such as metal, wood, bamboo, bone or even plastic. The key difference between crochet and knitting, beyond the implements used for their production, is that each stitch in crochet is completed before the next one is begun, while knitting keeps many stitches open at a time. Some variant forms of crochet, such as Tunisian crochet and broomstick lace, do keep multiple crochet stitches open at a time.

Knitting is a method for production of textile fabrics by interlacing yarn loops with loops of the same or other yarns. It is used to create many types of garments. Knitting may be done by hand or by machine.

Quilting is the process of joining a minimum of three layers of fabric together either through stitching manually using a needle and thread, or mechanically with a sewing machine or specialised longarm quilting system. An array of stitches is passed through all layers of the fabric to create a three-dimensional padded surface. The three layers are typically referred to as the top fabric or quilt top, batting or insulating material, and the backing.

Patchwork or "pieced work" is a form of needlework that involves sewing together pieces of fabric into a larger design. The larger design is usually based on repeating patterns built up with different fabric shapes. These shapes are carefully measured and cut, basic geometric shapes making them easy to piece together.

A sewing machine is a machine used to sew fabric and materials together with thread. Sewing machines were invented during the first Industrial Revolution to decrease the amount of manual sewing work performed in clothing companies. Since the invention of the first sewing machine, generally considered to have been the work of Englishman Thomas Saint in 1790, the sewing machine has greatly improved the efficiency and productivity of the clothing industry.

Appliqué is ornamental needlework in which pieces or patches of fabric in different shapes and patterns are sewn or stuck onto a larger piece to form a picture or pattern. It is commonly used as decoration, especially on garments. The technique is accomplished either by hand stitching or machine. Appliqué is commonly practised with textiles, but the term may be applied to similar techniques used on different materials. In the context of ceramics, for example, an appliqué is a separate piece of clay added to the primary work, generally for the purpose of decoration.

Sewing is the craft of fastening or attaching objects using stitches made with a sewing needle and thread. Sewing is one of the oldest of the textile arts, arising in the Paleolithic era. Before the invention of spinning yarn or weaving fabric, archaeologists believe Stone Age people across Europe and Asia sewed fur and leather clothing using bone, antler or ivory sewing-needles and "thread" made of various animal body parts including sinew, catgut, and veins.

A hem in sewing is a garment finishing method, where the edge of a piece of cloth is folded and sewn to prevent unravelling of the fabric and to adjust the length of the piece in garments, such as at the end of the sleeve or the bottom of the garment.

An overlock is a kind of stitch that sews over the edge of one or two pieces of cloth for edging, hemming, or seaming. Usually an overlock sewing machine will cut the edges of the cloth as they are fed through, though some are made without cutters. The inclusion of automated cutters allows overlock machines to create finished seams easily and quickly. An overlock sewing machine differs from a lockstitch sewing machine in that it uses loopers fed by multiple thread cones rather than a bobbin. Loopers serve to create thread loops that pass from the needle thread to the edges of the fabric so that the edges of the fabric are contained within the seam.

A sewing needle, used for hand-sewing, is a long slender tool with a pointed tip at one end and a hole to hold the sewing thread. The earliest needles were made of bone or wood; modern needles are manufactured from high carbon steel wire and are nickel- or 18K gold-plated for corrosion resistance. High-quality embroidery needles are plated with two-thirds platinum and one-third titanium alloy. Traditionally, needles have been kept in needle books or needlecases which have become objects of adornment. Sewing needles may also be kept in an étui, a small box that held needles and other items such as scissors, pencils and tweezers.

The Merrow Sewing Machine Company, best known for inventing the overlock sewing machine, is a manufacturer of sewing machines. After the explosion of his gunpowder mill in 1837, in 1838 J.M. Merrow built a knitting mill on the same site. The company developed crocheting machines for its own use and by 1887 evolved to design, build and market sewing machines exclusively. During its early decades it was organized as a partnership under various names: established in 1838 as Joseph M. Merrow & Sons by J. Makens Merrow, then Pitkin, Merrow, & Co., renamed Merrow Manufacturing Co. in 1857, then Merrow and Millard in 1863, J.B. Merrow and Sons in 1870, and incorporated as The Merrow Manufacturing Company in 1893. Originally all of its manufacturing was done at facilities in Merrow, Connecticut, and then in Hartford, Connecticut, after 1894. The company is currently based in Fall River, Massachusetts.

A selvage or selvedge is a "self-finished" edge of a piece of fabric which keeps it from unraveling and fraying. The term "self-finished" means that the edge does not require additional finishing work, such as hem or bias tape, to prevent fraying.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, which turns it into cloth. The machine used for weaving is the loom. For decoration, the process of colouring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

Helen Augusta Blanchard was an American inventor who received 28 patents between 1873 and 1915. She was known for her numerous inventions dealing with sewing machines and sewing technology.

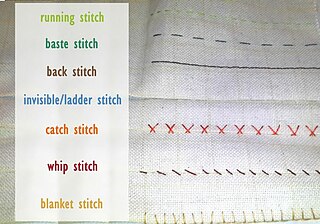

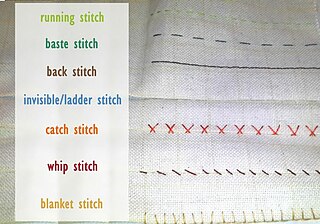

A whip stitch is a simple sewing stitch that is used in crocheting, knitting and sewing, in which the needle is passed in and out of the fabric in a series of stitches that circle an edge of the fabric. In hand sewing, this stitch can be used to create a seam but can also be used for joining two pieces together. Whip stitching creates a nice edge and prevents the fabric from unraveling.

The straight or running stitch is the basic stitch in hand-sewing and embroidery, on which all other forms of sewing are based. The stitch is worked by passing the needle in and out of the fabric at a regular distance. All other stitches are created by varying the straight stitch in length, spacing, and direction.

Sewing is the craft of fastening or attaching objects using stitches made with needle and thread. Sewing is one of the oldest of the textile arts, arising in the Paleolithic Era. Although usually associated with clothing and household linens, sewing is used in a variety of crafts and industries, including shoemaking, upholstery, sailmaking, bookbinding and the manufacturing of some kinds of sporting goods. Sewing is the fundamental process underlying a variety of textile arts and crafts, including embroidery, tapestry, quilting, appliqué and patchwork.

In sewing, a seam is the join where two or more layers of fabric, leather, or other materials are held together with stitches. Prior to the invention of the sewing machine, all sewing was done by hand. Seams in modern mass-produced household textiles, sporting goods, and ready-to-wear clothing are sewn by computerized machines, while home shoemaking, dressmaking, quilting, crafts, haute couture and tailoring may use a combination of hand and machine sewing.

Overcast stitch is a type of stitch used to enclose a raw, or unfinished, seam or edge. The purpose is to prevent unraveling of the fabric.