Cross-stitch is a form of sewing and a popular form of counted-thread embroidery in which X-shaped stitches in a tiled, raster-like pattern are used to form a picture. The stitcher counts the threads on a piece of evenweave fabric in each direction so that the stitches are of uniform size and appearance. This form of cross-stitch is also called counted cross-stitch in order to distinguish it from other forms of cross-stitch. Sometimes cross-stitch is done on designs printed on the fabric ; the stitcher simply stitches over the printed pattern. Cross-stitch is often executed on easily countable fabric called aida cloth, whose weave creates a plainly visible grid of squares with holes for the needle at each corner.

Knitting is a method for production of textile fabrics by interlacing yarn loops with loops of the same or other yarns. It is used to create many types of garments. Knitting may be done by hand or by machine.

A loom is a device used to weave cloth and tapestry. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. The precise shape of the loom and its mechanics may vary, but the basic function is the same.

Counted-thread embroidery is any embroidery in which the number of warp and weft yarns in a fabric are methodically counted for each stitch, resulting in uniform-length stitches and a precise, uniform embroidery pattern. Even-weave fabric is typically used, producing a symmetrical image, as both warp and weft yarns are evenly spaced.

Needlepoint is a type of canvas work, a form of embroidery in which yarn is stitched through a stiff open weave canvas. Traditionally needlepoint designs completely cover the canvas. Although needlepoint may be worked in a variety of stitches, many needlepoint designs use only a simple tent stitch and rely upon color changes in the yarn to construct the pattern. Needlepoint is the oldest form of canvas work.

Woven fabric is any textile formed by weaving. Woven fabrics are often created on a loom, and made of many threads woven on a warp and a weft. Technically, a woven fabric is any fabric made by interlacing two or more threads at right angles to one another. Woven fabrics can be made of natural fibers, synthetic fibers, or a mixture of both, such as cotton and polyester.

Twill is a type of textile weave with a pattern of diagonal parallel ribs. It is one of three fundamental types of weave, along with plain weave and satin. It is made by passing the weft thread over one or more warp threads then under two or more warp threads and so on, with a "step", or offset, between rows to create the characteristic diagonal pattern. Because of this structure, twill generally drapes well.

In the manufacture of cloth, warp and weft are the two basic components in weaving to transform thread and yarn into textile fabrics. The vertical warp yarns are held stationary in tension on a loom (frame) while the horizontal weft is drawn through the warp thread. In the terminology of weaving, each warp thread is called a warp end ; a pick is a single weft thread that crosses the warp thread.

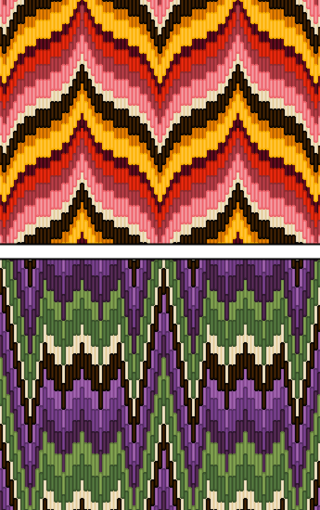

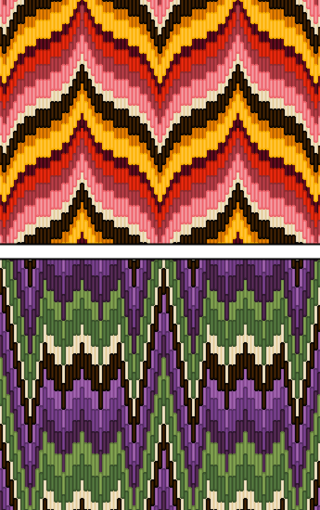

Bargello is a type of needlepoint embroidery consisting of upright flat stitches laid in a mathematical pattern to create motifs. The name originates from a series of chairs found in the Bargello palace in Florence, which have a "flame stitch" pattern.

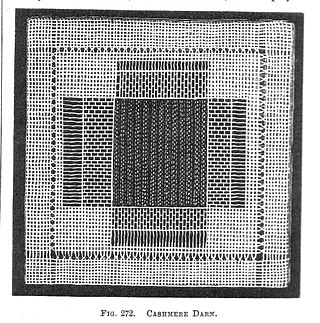

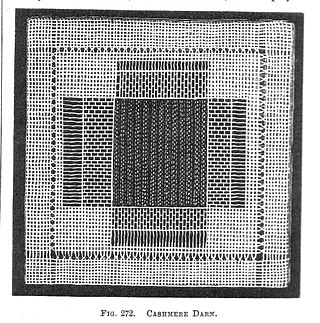

Darning is a sewing technique for repairing holes or worn areas in fabric or knitting using needle and thread alone. It is often done by hand, but using a sewing machine is also possible. Hand darning employs the darning stitch, a simple running stitch in which the thread is "woven" in rows along the grain of the fabric, with the stitcher reversing direction at the end of each row, and then filling in the framework thus created, as if weaving. Darning is a traditional method for repairing fabric damage or holes that do not run along a seam, and where patching is impractical or would create discomfort for the wearer, such as on the heel of a sock.

A balanced fabric is one in which the warp and the weft are of the same size. In weaving, these are generally called "balanced plain weaves" or just "balanced weaves", while in embroidery the term "even-weave" is more common.

Plain weave is the most basic of three fundamental types of textile weaves. It is strong and hard-wearing, and is used for fashion and furnishing fabrics. Fabrics with a plain weave are generally strong, durable, and have a smooth surface. They are often used for a variety of applications, including clothing, home textiles, and industrial fabrics.

Basic knitted fabrics include stocking stitch, reverse stocking stitch, garter stitch, seed stitch, faggoting, and tricot. In some cases, these fabrics appear differently on the right side than on the wrong side.

Knitted fabric is a textile that results from knitting, the process of inter-looping of yarns or inter-meshing of loops. Its properties are distinct from woven fabric in that it is more flexible and can be more readily constructed into smaller pieces, making it ideal for socks and hats.

A selvage or selvedge is a "self-finished" edge of a piece of fabric which keeps it from unraveling and fraying. The term "self-finished" means that the edge does not require additional finishing work, such as hem or bias tape, to prevent fraying.

Parisian stitch is a longer horizontal/vertical stitch used in needlepoint next to a smaller parallel stitch to create a basketweave pattern. The end points on either end alternate in a staggered pattern.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, which turns it into cloth. The machine used for weaving is the loom. For decoration, the process of colouring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

A knotted-pile carpet is a carpet containing raised surfaces, or piles, from the cut off ends of knots woven between the warp and weft. The Ghiordes/Turkish knot and the Senneh/Persian knot, typical of Anatolian carpets and Persian carpets, are the two primary knots. A flat or tapestry woven carpet, without pile, is a kilim. A pile carpet is influenced by width and number of warp and weft, pile height, knots used, and knot density.

A lazy line or section line is a technical feature of weaving which describes visible diagonal joins within a woven textile. It results from interlacing wefts joining adjacent warp sections woven at different times. Successive rows of turnarounds of discontinuous wefts create a diagonal line which, in pile rugs, is best seen from the back side, and from the front side only if the pile is heavily worn. A lazy line is created when the weaver does not finish a rug line by line from one side to the other, but sequentially finishes one area after the other.

Pin weaving is a form of small-scale weaving traditionally done on a frame made of pins; the warp and weft are wrapped around the pins. Pin-woven textiles have a selvage edge all the way around.