Filtration is a physical separation process that separates solid matter and fluid from a mixture using a filter medium that has a complex structure through which only the fluid can pass. Solid particles that cannot pass through the filter medium are described as oversize and the fluid that passes through is called the filtrate. Oversize particles may form a filter cake on top of the filter and may also block the filter lattice, preventing the fluid phase from crossing the filter, known as blinding. The size of the largest particles that can successfully pass through a filter is called the effective pore size of that filter. The separation of solid and fluid is imperfect; solids will be contaminated with some fluid and filtrate will contain fine particles. Filtration occurs both in nature and in engineered systems; there are biological, geological, and industrial forms.

Water purification is the process of removing undesirable chemicals, biological contaminants, suspended solids, and gases from water. The goal is to produce water that is fit for specific purposes. Most water is purified and disinfected for human consumption, but water purification may also be carried out for a variety of other purposes, including medical, pharmacological, chemical, and industrial applications. The history of water purification includes a wide variety of methods. The methods used include physical processes such as filtration, sedimentation, and distillation; biological processes such as slow sand filters or biologically active carbon; chemical processes such as flocculation and chlorination; and the use of electromagnetic radiation such as ultraviolet light.

Microfiltration is a type of physical filtration process where a contaminated fluid is passed through a special pore-sized membrane filter to separate microorganisms and suspended particles from process liquid. It is commonly used in conjunction with various other separation processes such as ultrafiltration and reverse osmosis to provide a product stream which is free of undesired contaminants.

Diatomaceous earth, diatomite, celite or kieselgur/kieselguhr is a naturally occurring, soft, siliceous sedimentary rock that can be crumbled into a fine white to off-white powder. It has a particle size ranging from more than 3 mm to less than 1 μm, but typically 10 to 200 μm. Depending on the granularity, this powder can have an abrasive feel, similar to pumice powder, and has a low density as a result of its high porosity. The typical chemical composition of oven-dried diatomaceous earth is 80–90% silica, with 2–4% alumina, and 0.5–2% iron oxide.

Sand filters are used as a step in the water treatment process of water purification.

In terms of water treatment, including water purification and sewage treatment, backwashing refers to pumping water backwards through the filters media, sometimes including intermittent use of compressed air during the process. Backwashing is a form of preventive maintenance so that the filter media can be reused. In water treatment plants, backwashing can be an automated process that is run by local programmable logic controllers (PLCs). The backwash cycle is triggered after a set time interval, when the filter effluent turbidity is greater than a treatment guideline or when the differential pressure across the filter exceeds a set value.

Cryptosporidium, sometimes called crypto, is an apicomplexan genus of alveolates which are parasites that can cause a respiratory and gastrointestinal illness (cryptosporidiosis) that primarily involves watery diarrhea, sometimes with a persistent cough.

Portable water purification devices are self-contained, easily transported units used to purify water from untreated sources for drinking purposes. Their main function is to eliminate pathogens, and often also of suspended solids and some unpalatable or toxic compounds.

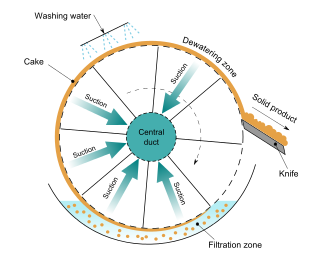

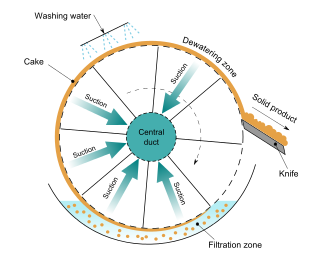

A Rotary Vacuum Filter Drum consists of a cylindrical filter membrane that is partly sub-merged in a slurry to be filtered. The inside of the drum is held lower than the ambient pressure. As the drum rotates through the slurry, the liquid is sucked through the membrane, leaving solids to cake on the membrane surface while the drum is submerged. A knife or blade is positioned to scrape the product from the surface.

In chemical engineering, biochemical engineering and protein purification, cross-flow filtration is a type of filtration. Cross-flow filtration is different from dead-end filtration in which the feed is passed through a membrane or bed, the solids being trapped in the filter and the filtrate being released at the other end. Cross-flow filtration gets its name because the majority of the feed flow travels tangentially across the surface of the filter, rather than into the filter. The principal advantage of this is that the filter cake is substantially washed away during the filtration process, increasing the length of time that a filter unit can be operational. It can be a continuous process, unlike batch-wise dead-end filtration.

Aquarium filters are critical components of both freshwater and marine aquaria. Aquarium filters remove physical and soluble chemical waste products from aquaria, simplifying maintenance. Furthermore, aquarium filters are necessary to support life as aquaria are relatively small, closed volumes of water compared to the natural environment of most fish.

Swimming pool sanitation is the process of ensuring healthy conditions in swimming pools. Proper sanitation is needed to maintain the visual clarity of water and to prevent the transmission of infectious waterborne diseases.

Black powder is an industry name for the abrasive, reactive particulate contamination present in all gas and hydrocarbon fluid transmission lines. Black powder ranges from light brown to black, and the mineral makeup varies per production field around the world.

Depth filters are filters that use a porous filtration medium to retain particles throughout the medium, rather than just on the surface of the medium. Depth filtration, typified by multiple porous layers with depth, is used to capture the solid contaminants from the liquid phase. These filters are commonly used when the fluid to be filtered contains a high load of particles because, relative to other types of filters, they can retain a large mass of particles before becoming clogged.

Filtered beer refers to any ale, lager, or fermented malt beverage in which the sediment left over from the brewing process has been removed. Ancient techniques included the use of straw mats, cloth, or straws, and frequently left some sediment in the drink. Modern filtration, introduced at the end of the 19th century, uses a mechanical process that can remove all sediment, including yeast, from the beer. Such beer is known as bright beer and requires force carbonation before bottling or serving from a keg. In the United Kingdom, a beer which has been filtered in the brewery is known as "brewery-conditioned", as opposed to unfiltered cask ales.

A vacuum ceramic filter is designed to separate liquids from solids for dewatering of ore concentrates purposes. The device consists of a rotator, slurry tank, ceramic filter plate, distributor, discharge scraper, cleaning device, frame, agitating device, pipe system, vacuum system, automatic acid dosing system, automatic lubricating system, valve and discharge chute. The operation and construction principle of vacuum ceramic filter resemble those of a conventional disc filter, but the filter medium is replaced by a finely porous ceramic disc. The disc material is inert, has a long operational life and is resistant to almost all chemicals. Performance can be optimized by taking into account all those factors which affect the overall efficiency of the separation process. Some of the variables affecting the performance of a vacuum ceramic filter include the solid concentration, speed rotation of the disc, slurry level in the feed basin, temperature of the feed slurry, and the pressure during dewatering stages and filter cake formation.

Membrane technology encompasses the scientific processes used in the construction and application of membranes. Membranes are used to facilitate the transport or rejection of substances between mediums, and the mechanical separation of gas and liquid streams. In the simplest case, filtration is achieved when the pores of the membrane are smaller than the diameter of the undesired substance, such as a harmful microorganism. Membrane technology is commonly used in industries such as water treatment, chemical and metal processing, pharmaceuticals, biotechnology, the food industry, as well as the removal of environmental pollutants.

A pusher centrifuge is a type of filtration technique that offers continuous operation to de-water and wash materials such as relatively in-compressible feed solids, free-draining crystalline, polymers and fibrous substances. It consists of a constant speed rotor and is fixed to one of several baskets. This assembly is applied with centrifugal force that is generated mechanically for smaller units and hydraulically for larger units to enable separation.

The peeler centrifuge is a device that performs by rotating filtration basket in an axis. A centrifuge follows on the principle of centrifugal force to separate solids from liquids by density difference. High rotation speed provides high centrifugal force that allows the suspended solid in feed to settle on the inner surface of basket. There are three kinds of centrifuge, horizontal, vertical peeler centrifuge and siphon peeler centrifuge. These classes of instrument apply to various areas such as fertilisers, pharmaceutical, plastics and food including artificial sweetener and modified starch.

Gravity filtration is a method of filtering impurities from solutions by using gravity to pull liquid through a filter. The two main kinds of filtration used in laboratories are gravity and vacuum/suction. Gravity filtration is often used in chemical laboratories to filter precipitates from precipitation reactions as well as drying agents, inadmissible side items, or remaining reactants. While it can also be used to separate out strong products, vacuum filtration is more commonly used for this purpose.