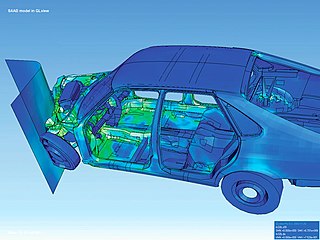

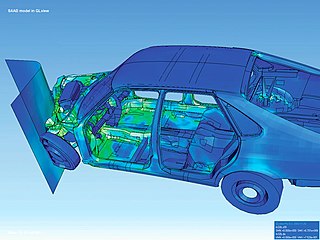

Structural analysis is the determination of the effects of loads on physical structures and their components. Structures subject to this type of analysis include all that must withstand loads, such as buildings, bridges, aircraft and ships. Structural analysis employs the fields of applied mechanics, materials science and applied mathematics to compute a structure's deformations, internal forces, stresses, support reactions, accelerations, and stability. The results of the analysis are used to verify a structure's fitness for use, often precluding physical tests. Structural analysis is thus a key part of the engineering design of structures.

Solid mechanics, also known as mechanics of solids, is the branch of continuum mechanics that studies the behavior of solid materials, especially their motion and deformation under the action of forces, temperature changes, phase changes, and other external or internal agents.

Numerical methods for partial differential equations is the branch of numerical analysis that studies the numerical solution of partial differential equations (PDEs).

Mesh generation is the practice of creating a mesh, a subdivision of a continuous geometric space into discrete geometric and topological cells. Often these cells form a simplicial complex. Usually the cells partition the geometric input domain. Mesh cells are used as discrete local approximations of the larger domain. Meshes are created by computer algorithms, often with human guidance through a GUI, depending on the complexity of the domain and the type of mesh desired. The goal is to create a mesh that accurately captures the input domain geometry, with high-quality (well-shaped) cells, and without so many cells as to make subsequent calculations intractable. The mesh should also be fine in areas that are important for the subsequent calculations.

Micromechanics is the analysis of composite or heterogeneous materials on the level of the individual constituents that constitute these materials.

In the numerical solution of partial differential equations, a topic in mathematics, the spectral element method (SEM) is a formulation of the finite element method (FEM) that uses high degree piecewise polynomials as basis functions. The spectral element method was introduced in a 1984 paper by A. T. Patera. Although Patera is credited with development of the method, his work was a rediscovery of an existing method

AFGROW is a Damage Tolerance Analysis (DTA) computer program that calculates crack initiation, fatigue crack growth, and fracture to predict the life of metallic structures. Originally developed by the Air Force Research Laboratory, AFGROW is mainly used for aerospace applications, but can be applied to any type of metallic structure that experiences fatigue cracking.

COOLFluiD is a component based scientific computing environment that handles high-performance computing problems with focus on complex computational fluid dynamics (CFD) involving multiphysics phenomena.

The finite element method (FEM) is a widely used method for numerically solving differential equations arising in engineering and mathematical modeling. Typical problem areas of interest include the traditional fields of structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential.

NEi Software, founded as Noran Engineering, Inc. in 1991, is an engineering software company that develops, publishes and promotes FEA software programs including its flagship product NEi Nastran. The FEA algorithms allow engineers to analyze how a structure will behave under a variety of conditions. The types of analysis include linear and nonlinear stress, dynamic, and heat transfer analysis. MCT, PPFA, dynamic design analysis method, optimization, fatigue, CFD and event simulation are just some of the specialized types of analysis supported by the company.

hp-FEM is a general version of the finite element method (FEM), a numerical method for solving partial differential equations based on piecewise-polynomial approximations that employs elements of variable size (h) and polynomial degree (p). The origins of hp-FEM date back to the pioneering work of Barna A. Szabó and Ivo Babuška who discovered that the finite element method converges exponentially fast when the mesh is refined using a suitable combination of h-refinements (dividing elements into smaller ones) and p-refinements. The exponential convergence makes the method a very attractive choice compared to most other finite element methods which only converge with an algebraic rate. The exponential convergence of the hp-FEM was not only predicted theoretically but also observed by numerous independent researchers.

The theory of micro-mechanics of failure aims to explain the failure of continuous fiber reinforced composites by micro-scale analysis of stresses within each constituent material, and of the stresses at the interfaces between those constituents, calculated from the macro stresses at the ply level.

Smoothed finite element methods (S-FEM) are a particular class of numerical simulation algorithms for the simulation of physical phenomena. It was developed by combining meshfree methods with the finite element method. S-FEM are applicable to solid mechanics as well as fluid dynamics problems, although so far they have mainly been applied to the former.

Weakened weak form is used in the formulation of general numerical methods based on meshfree methods and/or finite element method settings. These numerical methods are applicable to solid mechanics as well as fluid dynamics problems.

VisualFEA is a finite element analysis software program for Microsoft Windows and Mac OS X. It is developed and distributed by Intuition Software, Inc. of South Korea, and used chiefly for structural and geotechnical analysis. Its strongest point is its intuitive, user-friendly design based on graphical pre- and postprocessing capabilities. It has educational features for teaching and learning structural mechanics, and finite element analysis through graphical simulation. It is widely used in college-level courses related to structural mechanics and finite element methods.

The discrete least squares meshless (DLSM) method is a meshless method based on the least squares concept. The method is based on the minimization of a least squares functional, defined as the weighted summation of the squared residual of the governing differential equation and its boundary conditions at nodal points used to discretize the domain and its boundaries. While most of the existing meshless methods need background cells for numerical integration, DLSM did not require a numerical integration procedure due to the use of the discrete least squares method to discretize the governing differential equation. A Moving least squares (MLS) approximation method is used to construct the shape function, making the approach a fully least squares-based approach.

p-FEM or the p-version of the finite element method is a numerical method for solving partial differential equations. It is a discretization strategy in which the finite element mesh is fixed and the polynomial degrees of elements are increased such that the lowest polynomial degree, denoted by , approaches infinity. This is in contrast with the "h-version" or "h-FEM", a widely used discretization strategy, in which the polynomial degrees of elements are fixed and the mesh is refined such that the diameter of the largest element, denoted by approaches zero.

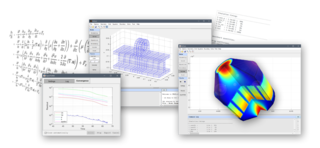

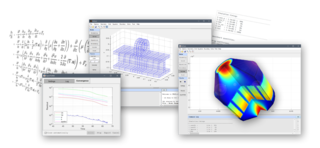

FEATool Multiphysics is a physics, finite element analysis (FEA), and PDE simulation toolbox. FEATool Multiphysics features the ability to model fully coupled heat transfer, fluid dynamics, chemical engineering, structural mechanics, fluid-structure interaction (FSI), electromagnetics, as well as user-defined and custom PDE problems in 1D, 2D (axisymmetry), or 3D, all within a graphical user interface (GUI) or optionally as script files. FEATool has been employed and used in academic research, teaching, and industrial engineering simulation contexts.

Barna A. Szabó is a Hungarian-American engineer and educator, noted for his contributions on the finite element method, particularly the conception and implementation of the p- and hp-versions of the Finite Element Method. He is a founding member and fellow of the United States Association for Computational Mechanics, an external member of the Hungarian Academy of Sciences and fellow of the St. Louis Academy of Sciences.