Cob, cobb, or clom is a natural building material made from subsoil, water, fibrous organic material, and sometimes lime. The contents of subsoil vary, and if it does not contain the right mixture, it can be modified with sand or clay. Cob is fireproof, termite proof, resistant to seismic activity, and uses low-cost materials, although it is very labour intensive. It can be used to create artistic and sculptural forms, and its use has been revived in recent years by the natural building and sustainability movements.

Contour crafting is a building printing technology being researched by Behrokh Khoshnevis of the University of Southern California's Information Sciences Institute that uses a computer-controlled crane or gantry to build edifices rapidly and efficiently with substantially less manual labor. It was originally conceived as a method to construct molds for industrial parts. Khoshnevis decided to adapt the technology for rapid home construction as a way to rebuild after natural disasters, like the devastating earthquakes that have plagued his native Iran.

Stereolithography is a form of 3D printing technology used for creating models, prototypes, patterns, and production parts in a layer by layer fashion using photochemical processes by which light causes chemical monomers and oligomers to cross-link together to form polymers. Those polymers then make up the body of a three-dimensional solid. Research in the area had been conducted during the 1970s, but the term was coined by Chuck Hull in 1984 when he applied for a patent on the process, which was granted in 1986. Stereolithography can be used to create prototypes for products in development, medical models, and computer hardware, as well as in many other applications. While stereolithography is fast and can produce almost any design, it can be expensive.

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer control, with the material being added together, typically layer by layer.

Green building refers to both a structure and the application of processes that are environmentally responsible and resource-efficient throughout a building's life-cycle: from planning to design, construction, operation, maintenance, renovation, and demolition. This requires close cooperation of the contractor, the architects, the engineers, and the client at all project stages. The Green Building practice expands and complements the classical building design concerns of economy, utility, durability, and comfort. Green building also refers to saving resources to the maximum extent, including energy saving, land saving, water saving, material saving, etc., during the whole life cycle of the building, protecting the environment and reducing pollution, providing people with healthy, comfortable and efficient use of space, and being in harmony with nature. Buildings that live in harmony; green building technology focuses on low consumption, high efficiency, economy, environmental protection, integration and optimization.’

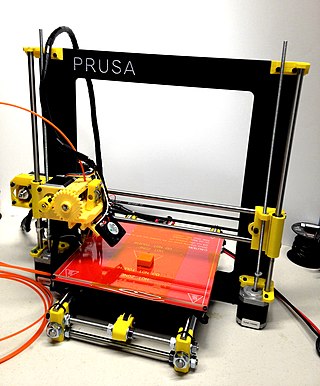

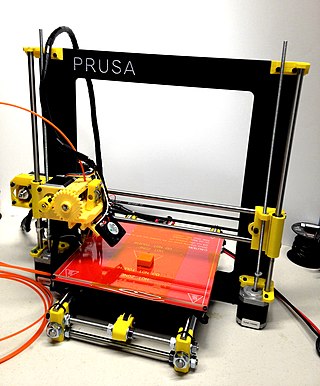

RepRap is a project to develop low-cost 3D printers that can print most of their own components. As open designs, all of the designs produced by the project are released under a free software license, the GNU General Public License.

3D Systems Corporation is an American company based in Rock Hill, South Carolina, that engineers, manufactures, and sells 3D printers, 3D printing materials, 3D printed parts, and application engineering services. The company creates product concept models, precision and functional prototypes, master patterns for tooling, as well as production parts for direct digital manufacturing. It uses proprietary processes to fabricate physical objects using input from computer-aided design and manufacturing software, or 3D scanning and 3D sculpting devices.

Stratasys, Ltd. is an American-Israeli manufacturer of 3D printers, software, and materials for polymer additive manufacturing as well as 3D-printed parts on-demand. The company is incorporated in Israel. Engineers use Stratasys systems to model complex geometries in a wide range of polymer materials, including: ABS, polyphenylsulfone (PPSF), polycarbonate (PC) and polyetherimide and Nylon 12.

Neri Oxman is an Israeli-American designer and former professor known for art that combines design, biology, computing, and materials engineering. She coined the phrase "material ecology" to define her work.

Open Source Ecology (OSE) is a network of farmers, engineers, architects and supporters, whose main goal is the eventual manufacturing of the Global Village Construction Set (GVCS). As described by Open Source Ecology "the GVCS is an open technological platform that allows for the easy fabrication of the 50 types of industrial machines that it takes to build a small civilization with modern comforts". Groups in Oberlin, Ohio, Pennsylvania, New York and California are developing blueprints, and building prototypes in order to test them on the Factor e Farm in rural Missouri. 3D-Print.com reports that OSE has been experimenting with RepRap 3-D printers, as suggested by academics for sustainable development.

The environmental impact of concrete, its manufacture, and its applications, are complex, driven in part by direct impacts of construction and infrastructure, as well as by CO2 emissions; between 4-8% of total global CO2 emissions come from concrete. Many depend on circumstances. A major component is cement, which has its own environmental and social impacts and contributes largely to those of concrete.

Construction 3D Printing (c3Dp) or 3D construction Printing (3DCP) refers to various technologies that use 3D printing as a core method to fabricate buildings or construction components. Alternative terms for this process include "additive construction." "3D Concrete" refers to concrete extrusion technologies whereas Autonomous Robotic Construction System (ARCS), large-scale additive manufacturing (LSAM), and freeform construction (FC) refer to other sub-groups.

Fused filament fabrication (FFF), also known as fused deposition modeling, or filament freeform fabrication, is a 3D printing process that uses a continuous filament of a thermoplastic material. Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work. The print head is moved under computer control to define the printed shape. Usually the head moves in two dimensions to deposit one horizontal plane, or layer, at a time; the work or the print head is then moved vertically by a small amount to begin a new layer. The speed of the extruder head may also be controlled to stop and start deposition and form an interrupted plane without stringing or dribbling between sections. "Fused filament fabrication" was coined by the members of the RepRap project to give an acronym (FFF) that would be legally unconstrained in its use.

In recent years, 3D printing has developed significantly and can now perform crucial roles in many applications, with the most common applications being manufacturing, medicine, architecture, custom art and design, and can vary from fully functional to purely aesthetic applications.

A variety of processes, equipment, and materials are used in the production of a three-dimensional object via additive manufacturing. 3D printing is also known as additive manufacturing, because the numerous available 3D printing process tend to be additive in nature, with a few key differences in the technologies and the materials used in this process.

Sustainable construction aims to reduce the negative health and environmental impacts caused by the construction process and by the operation and use of buildings and the built environment. It can be seen as the construction industry's contribution to more sustainable development. Precise definitions vary from place to place, and are constantly evolving to encompass varying approaches and priorities. More comprehensively, sustainability can be considered from three dimension of planet, people and profit across the entire construction supply chain. Key concepts include the protection of the natural environment, choice of non-toxic materials, reduction and reuse of resources, waste minimization, and the use of life-cycle cost analysis.

Carbon negative architecture is architecture whose construction, operation and eventual demolition results in more atmospheric carbon and greenhouse gases removed from the atmosphere than that which is emitted as consequence of the same. This is achieved by rigorous planning, regenerative architectural design and on-site carbon sequestration. Such buildings go beyond the carbon-neutral or net-zero approach, which simply means that buildings can still emit CO2 as long as the operators offset (or remove) those emissions from the atmosphere by the same amount in other places.

3D concrete printing, or simply concrete printing, refers to digital fabrication processes for cementitious materials based on one of several different 3D printing technologies. 3D-printed concrete eliminates the need for formwork, reducing material waste and allowing for greater geometric freedom in complex structures. With recent developments in mix design and 3D printing technology over the last decade, 3D concrete printing has grown exponentially since its emergence in the 1990s. Architectural and structural applications of 3D-printed concrete include the production of building blocks, building modules, street furniture, pedestrian bridges, and low-rise residential structures.

Luyten 3d is an Australian, Melbourne based, robotics and 3D printers manufacturing company, that designs and manufactures AI mobile 3D printers and 3D printing mix for the building and construction industry.

Bio-based building materials incorporate biomass, which is derived from renewable materials of biological origin such as plants,, animals, enzymes, and microorganisms, including bacteria, fungi, and yeast.