Chocolate is a preparation of roasted and ground cacao seeds that is made in the form of a liquid, paste, or in a block, which may also be used as a flavoring ingredient in other foods. The earliest signs of use are associated with Olmec sites suggesting consumption of chocolate beverages, dating from 19 centuries BCE. The majority of Mesoamerican people made chocolate beverages, including the Maya and Aztecs. The word chocolate is derived from the Spanish word chocolate, deriving in turn from the Classical Nahuatl word xocolātl.

Nutella is a brand of sweetened hazelnut cocoa spread. Nutella is manufactured by the Italian company Ferrero and was first introduced in 1964, although its first iteration dates to 1963.

Candy, also called sweets or lollies, is a confection that features sugar as a principal ingredient. The category, called sugar confectionery, encompasses any sweet confection, including chocolate, chewing gum, and sugar candy. Vegetables, fruit, or nuts which have been glazed and coated with sugar are said to be candied.

Chocolate milk is a sweetened chocolate-flavored milk. It can be made by mixing chocolate syrup with milk. It can be purchased pre-mixed with milk or made at home by blending milk with cocoa powder and a sweetener, melted chocolate, chocolate syrup, or a pre-made powdered chocolate milk mix. Other ingredients, such as starch, salt, carrageenan, vanilla, or artificial flavoring are sometimes added. To add nutritional value to the product, sometimes some minerals like zinc oxide or iron are added.

Animal fats and oils are lipid materials derived from animals. Physically, oils are liquid at room temperature, and fats are solid. Chemically, both fats and oils are composed of triglycerides. Although many animal parts and secretions may yield oil, in commercial practice, oil is extracted primarily from rendered tissue fats obtained from livestock animals like pigs, chickens and cows. Dairy products also yield popular animal fat and oil products such as cheese, butter, and milk.

Ghee is a class of clarified butter that originated in ancient India. It is commonly used in cuisine of the Indian subcontinent, Middle Eastern cuisine, Southeast Asian cuisine, traditional medicine, and religious rituals.

Cocoa butter, also called theobroma oil, is a pale-yellow, edible fat extracted from the cocoa bean. It is used to make chocolate, as well as some ointments, toiletries, and pharmaceuticals. Cocoa butter has a cocoa flavor and aroma. Its melting point is just below human body temperature.

Blue cheese or bleu cheese is cheese made with cultures of the mold Penicillium, giving it spots or veins of the mold throughout the cheese, which can vary in color through various shades of blue and green. This carries a distinct smell, either from that or various specially cultivated bacteria. Some blue cheeses are injected with spores before the curds form, and others have spores mixed in with the curds after they form. Blue cheeses are typically aged in a temperature-controlled environment such as a cave. Blue cheese can be eaten by itself or can be spread, crumbled or melted into or over a range of other foods. Blue cheese is known for its pungent creamy texture.

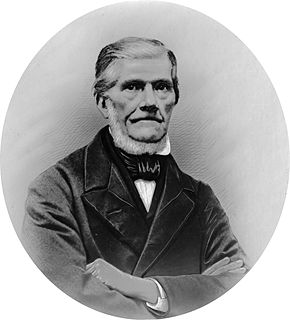

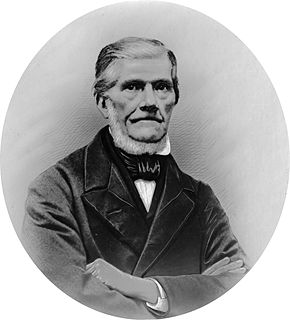

Coenraad Johannes van Houten was a Dutch chemist and chocolate maker known for the treatment of cocoa mass with alkaline salts to remove the bitter taste and make cocoa solids more water-soluble; the resulting product is still called "Dutch process chocolate". He is also credited with introducing a method for pressing the fat from roasted cocoa beans, though this was in fact his father, Casparus van Houten's invention.

Churning is the process of shaking up cream or whole milk to make butter, usually using a butter churn. In Europe from the Middle Ages until the Industrial Revolution, a churn was usually as simple as a barrel with a plunger in it, moved by hand. These have mostly been replaced by mechanical churns.

Big Turk is a candy bar manufactured by Nestlé Canada, that consists of dark magenta Turkish delight coated in a chocolate coating.

Polyglycerol polyricinoleate (PGPR), E476, is an emulsifier made from glycerol and fatty acids. In chocolate, compound chocolate and similar coatings, PGPR is mainly used with another substance like lecithin to reduce viscosity. It is used at low levels, and works by decreasing the friction between the solid particles in molten chocolate, reducing the yield stress so that it flows more easily, approaching the behaviour of a Newtonian fluid. It can also be used as an emulsifier in spreads and in salad dressings, or to improve the texture of baked goods. It is made up of a short chain of glycerol molecules connected by ether bonds, with ricinoleic acid side chains connected by ester bonds.

Chocolate is a range of foods derived from cocoa (cacao), mixed with fat and finely powdered sugar to produce a solid confectionery. There are several types of chocolate, classified according to the proportion of cocoa used in a particular formulation.

Hershey Kissables were a chocolate candy sold by The Hershey Company from late 2005 to 2009. Comparable to M&M's, Hershey Kissables were shaped like miniature Hershey's Kisses and were coated in a thick sugar shell.

Hershey's Cookies 'n' Creme is a candy bar manufactured by The Hershey Company.

Chocolate bloom is either of two types of whitish coating that can appear on the surface of chocolate: fat bloom, caused by changes in the fat crystals in the chocolate; and sugar bloom, due to crystals formed by the action of moisture on the sugar. Fat and sugar bloom damage the appearance of chocolate and limit its shelf life. Chocolate that has "bloomed" is still safe to eat, but may have an unappetizing appearance and surface texture. Chocolate bloom can be repaired by melting the chocolate down, stirring it, then pouring it into a mold and allowing it to cool, bringing the sugar or fat back into the solution.

The following outline is provided as an overview of and topical guide to chocolate:

Sour cream or soured cream is a dairy product obtained by fermenting regular cream with certain kinds of lactic acid bacteria. The bacterial culture, which is introduced either deliberately or naturally, sours and thickens the cream. Its name comes from the production of lactic acid by bacterial fermentation, which is called souring. Crème fraîche is one type of sour cream with a high fat content and less sour taste.

Pasta processing is the process in which wheat semolina or flour is mixed with water and the dough is extruded to a specific shape, dried and packaged.