Miso is a traditional Japanese seasoning produced by fermenting soybeans with salt and kōji and sometimes rice, barley, seaweed, or other ingredients. The result is a thick paste used for sauces and spreads, pickling vegetables, fish, or meats, and mixing with dashi soup stock to serve as miso soup called misoshiru (味噌汁), a Japanese culinary staple. High in protein and rich in vitamins and minerals, miso played an important nutritional role in feudal Japan. Miso is still widely used in Japan, both in traditional and modern cooking, and has been gaining worldwide interest.

Fish sauce is a liquid condiment made from fish or krill that have been coated in salt and fermented for up to two years. It is widely used as a staple seasoning in East and Southeast Asian cuisine.

Soy sauce is a liquid condiment of Chinese origin, traditionally made from a fermented paste of soybeans, roasted grain, brine, and Aspergillus oryzae or Aspergillus sojae molds. It is considered to contain a strong umami flavor.

Monosodium glutamate (MSG), also known as sodium glutamate, is the sodium salt of glutamic acid. MSG is found naturally in some foods including tomatoes and cheese. MSG is used in cooking as a flavor enhancer with an umami taste that intensifies the meaty, savory flavor of food, as naturally occurring glutamate does in foods such as stews and meat soups.

Umami, or savoriness, is one of the five basic tastes. It has been described as savory and is characteristic of broths and cooked meats.

Glutamic acid is an α-amino acid that is used by almost all living beings in the biosynthesis of proteins. It is non-essential in humans, meaning the body can synthesize it. It is also an excitatory neurotransmitter, in fact the most abundant one, in the vertebrate nervous system. It serves as the precursor for the synthesis of the inhibitory gamma-aminobutyric acid (GABA) in GABA-ergic neurons.

Dashi is a family of stocks used in Japanese cuisine. Dashi forms the base for miso soup, clear broth soup, noodle broth soup, and many simmering liquids to accentuate the savory flavor known as umami. Dashi is also mixed into the flour base of some grilled foods like okonomiyaki and takoyaki.

The Maillard reaction is a chemical reaction between amino acids and reducing sugars that gives browned food its distinctive flavor. Seared steaks, fried dumplings, cookies and other kinds of biscuits, breads, toasted marshmallows, and many other foods undergo this reaction. It is named after French chemist Louis Camille Maillard, who first described it in 1912 while attempting to reproduce biological protein synthesis. The reaction is a form of non-enzymatic browning which typically proceeds rapidly from around 140 to 165 °C. Many recipes call for an oven temperature high enough to ensure that a Maillard reaction occurs. At higher temperatures, caramelization and subsequently pyrolysis become more pronounced.

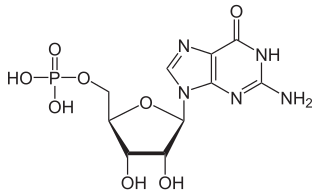

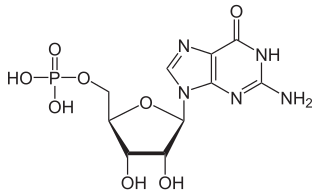

Guanosine monophosphate (GMP), also known as 5'-guanidylic acid or guanylic acid, is a nucleotide that is used as a monomer in RNA. It is an ester of phosphoric acid with the nucleoside guanosine. GMP consists of the phosphate group, the pentose sugar ribose, and the nucleobase guanine; hence it is a ribonucleoside monophosphate. Guanosine monophosphate is commercially produced by microbial fermentation. It is known as E number reference E626.

Industrial fermentation is the intentional use of fermentation by microorganisms such as bacteria and fungi as well as eukaryotic cells like CHO cells and insect cells, to make products useful to humans. Fermented products have applications as food as well as in general industry. Some commodity chemicals, such as acetic acid, citric acid, and ethanol are made by fermentation. The rate of fermentation depends on the concentration of microorganisms, cells, cellular components, and enzymes as well as temperature, pH and for aerobic fermentation oxygen. Product recovery frequently involves the concentration of the dilute solution. Nearly all commercially produced enzymes, such as lipase, invertase and rennet, are made by fermentation with genetically modified microbes. In some cases, production of biomass itself is the objective, like Single-cell protein and as in the case of baker's yeast and lactic acid bacteria starter cultures for cheesemaking. In general, fermentations can be divided into four types:

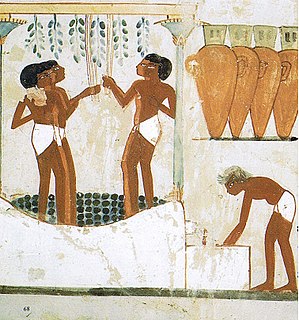

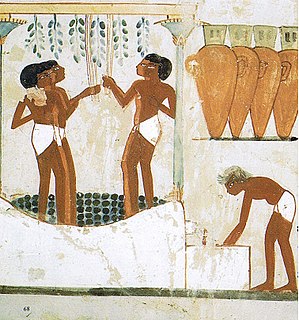

Fermentation in food processing is the process of converting carbohydrates to alcohol or organic acids using microorganisms—yeasts or bacteria—under anaerobic conditions. Fermentation usually implies that the action of microorganisms is desired. The science of fermentation is known as zymology or zymurgy.

Fermented bean paste is a category of fermented foods typically made from ground soybeans, which are indigenous to the cuisines of East, South and Southeast Asia. In some cases, such as the production of miso, other varieties of beans, such as broad beans, may also be used.

Fed-batch culture is, in the broadest sense, defined as an operational technique in biotechnological processes where one or more nutrients (substrates) are fed (supplied) to the bioreactor during cultivation and in which the product(s) remain in the bioreactor until the end of the run. An alternative description of the method is that of a culture in which "a base medium supports initial cell culture and a feed medium is added to prevent nutrient depletion". It is also a type of semi-batch culture. In some cases, all the nutrients are fed into the bioreactor. The advantage of the fed-batch culture is that one can control concentration of fed-substrate in the culture liquid at arbitrarily desired levels.

SCOBY is the commonly used acronym for "symbiotic culture of bacteria and yeast", and is formed after the completion of a unique fermentation process of lactic acid bacteria (LAB), acetic acid bacteria (AAB), and yeast to form several sour foods and beverages such as kombucha and kimchi. Beer and wine also undergo fermentation with yeast, but the lactic acid bacteria and acetic acid bacteria components unique to SCOBY are usually viewed as a source of spoilage rather than a desired addition. Both LAB and AAB enter on the surface of barley and malt in beer fermentation and grapes in wine fermentation; LAB lower the pH of the beer while AAB take the ethanol produced from the yeast and oxidize it further into vinegar, resulting in a sour taste and smell. AAB are also responsible for the formation of the cellulose SCOBY.

Glutamate flavoring is a generic name for the flavor-enhancing compounds based on glutamic acid and its salts (glutamates). These compounds provide an umami (savory) taste to food.

Sake kasu (酒粕) or sake lee is a cooking ingredient that is white in color with a paste-like texture. The taste of sake kasu is fruity and has a similar taste to Japanese sake. Sake kasu is the lees left over from sake production. It is a by-product of Japanese sake production that contains 8% of alcohol, high nutritious values and provides health benefits. Sake Kasu can be used as a marinade base in different Japanese dishes such as fish, vegetables, and meat, enhancing the umami flavor of the dish. Sake kasu can also be found in cosmetics and skincare products. Sake kasu is considered as a part of the Japanese “no waste” culture since the waste of the sake production is used in various ways. Mirin, a type of sweet Japanese sake can also produce kasu called mirin kasu. Similar to sake kasu, mirin kasu can also be used as a healthy food ingredient.

Alkylpyrazines are chemical compounds based on pyrazine with different substitution patterns. Some alkylpyrazines are naturally occurring highly aromatic substances which often have a very low odor threshold and contribute to the taste and aroma of various foods including cocoa, baked goods, coffee and wines. Alkylpyrazines are also formed during the cooking of some foods via Maillard reactions.

Chinese pickles or Chinese preserved vegetables consist of various vegetables or fruits that have been fermented by pickling with salt and brine, or marinated in mixtures based on soy sauce or savory bean pastes. The former is usually done using high-fiber vegetables and fruits, such as Chinese cabbage, carrot, apple and pineapple, while the latter marinated group is made using a wide variety of vegetables, ranging from mustards and cucumbers to winter melon and radishes. As of now, there are more than 130 kinds of pickles.

Symbiotic fermentation is a form of fermentation in which multiple organisms interact in order to produce the desired product. For example, a yeast may produce ethanol, which is then consumed by an acetic acid bacterium. Described early on as the fermentation of sugars following saccharification in a mixed fermentation process.

The chemical compounds in beer give it a distinctive taste, smell and appearance. The majority of compounds in beer come from the metabolic activities of plants and yeast and so are covered by the fields of biochemistry and organic chemistry. The main exception is that beer contains over 90% water and the mineral ions in the water (hardness) can have a significant effect upon the taste.