The Kennet and Avon Canal is a waterway in southern England with an overall length of 87 miles (140 km), made up of two lengths of navigable river linked by a canal. The name is used to refer to the entire length of the navigation rather than solely to the central canal section. From Bristol to Bath the waterway follows the natural course of the River Avon before the canal links it to the River Kennet at Newbury, and from there to Reading on the River Thames. In all, the waterway incorporates 105 locks.

The Watt steam engine design became synonymous with steam engines, and it was many years before significantly new designs began to replace the basic Watt design.

Boulton & Watt was an early British engineering and manufacturing firm in the business of designing and making marine and stationary steam engines. Founded in the English West Midlands around Birmingham in 1775 as a partnership between the English manufacturer Matthew Boulton and the Scottish engineer James Watt, the firm had a major role in the Industrial Revolution and grew to be a major producer of steam engines in the 19th century.

Steam power developed slowly over a period of several hundred years, progressing through expensive and fairly limited devices in the early 17th century, to useful pumps for mining in 1700, and then to Watt's improved steam engine designs in the late 18th century. It is these later designs, introduced just when the need for practical power was growing due to the Industrial Revolution, that truly made steam power commonplace.

Claymills Pumping Station is a restored Victorian sewage pumping station on the north side of Burton upon Trent, Staffordshire, England DE13 0DA. It was designed by James Mansergh and used to pump sewage to the sewage farm at Egginton.

Claverton Pumping Station in the village of Claverton, in the English county of Somerset, pumps water from the River Avon to the Kennet and Avon Canal using power from the flow of the river. It is a Grade I listed building, having been upgraded from Grade II in 2019.

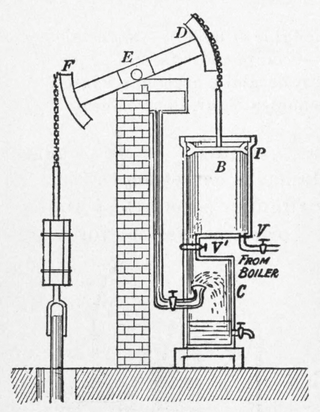

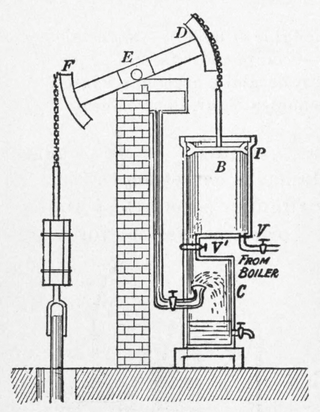

A beam engine is a type of steam engine where a pivoted overhead beam is used to apply the force from a vertical piston to a vertical connecting rod. This configuration, with the engine directly driving a pump, was first used by Thomas Newcomen around 1705 to remove water from mines in Cornwall. The efficiency of the engines was improved by engineers including James Watt, who added a separate condenser; Jonathan Hornblower and Arthur Woolf, who compounded the cylinders; and William McNaught, who devised a method of compounding an existing engine. Beam engines were first used to pump water out of mines or into canals but could be used to pump water to supplement the flow for a waterwheel powering a mill.

London Museum of Water & Steam is an independent museum founded in 1975 as the Kew Bridge Steam Museum. It was rebranded in early 2014 following a major investment project.

The Westonzoyland Pumping Station Museum of Steam Power and Land Drainage is a small industrial heritage museum dedicated to steam powered machinery at Westonzoyland in the English county of Somerset. It is a Grade II* listed building.

A Cornish engine is a type of steam engine developed in Cornwall, England, mainly for pumping water from a mine. It is a form of beam engine that uses steam at a higher pressure than the earlier engines designed by James Watt. The engines were also used for powering man engines to assist the underground miners' journeys to and from their working levels, for winching materials into and out of the mine, and for powering on-site ore stamping machinery.

Crofton Locks are a flight of locks on the Kennet and Avon Canal, near the village of Great Bedwyn, Wiltshire, England.

Wilton Water is a small reservoir, southwest of the village of Great Bedwyn in the English county of Wiltshire, which supplies the summit pound of the Kennet and Avon Canal with water. The reservoir lies in the parish of Grafton and collects rainfall from the eastern end of the Vale of Pewsey and the surrounding hills.

The Engine Arm or Birmingham Feeder Arm near Smethwick, West Midlands, England, is a short canal which was originally part of a feeder tunnel for a pumping engine. When the Smethwick flight of locks were reduced from six to three, the pumping engine was moved to a new site, which allowed part of the feeder tunnel to be opened up and made navigable, so that coal supplies for the engine could be delivered by barge. The Engine Arm also supplied the pumped water to the 473-foot (144 m) Wolverhampton level of the lowered summit. The arm was extended between 1825 and 1830 by Thomas Telford to carry water from Rotton Park Reservoir to the Old Main Line of the BCN Main Line Canal, and the Engine Arm Aqueduct was inserted to carry it over the new main line constructed at that time, which was 20 feet (6.1 m) lower. The arm is now managed by the Canal and River Trust and the basin beyond the site of the pumping station, which was replaced by a new engine house near Brasshouse Lane bridge in 1892, is used for residential moorings.

Shudehill Mill or Simpson's Mill was a very early cotton mill in Manchester city centre, England. It was built in 1782 by for Richard Arkwright and his partners and destroyed by fire in 1854. It was rebuilt and finally destroyed during the Manchester Blitz in 1940. One of Arkwright's larger mills, it was built three years before his patent lapsed. The mill had a 30 feet diameter water wheel and a Newcomen atmospheric engine was installed. Doubts remain as to why the engine was installed, whether it was a failed attempt to power a mill directly by steam or was modified to assist the wheel. It is possible that this engine, constructed by Hunt, could have been one of the 13 engines installed in Manchester mills by Joshua Wrigley. Water from the upper storage pond turned the water wheel to drive the mill. The steam engine recycled water from the lower storage pond to the upper storage pond. Three more Boulton and Watt engines were installed to power the increasing number of spindles.

The Leawood Pump House was built near Cromford, Derbyshire, England in 1849 to supply water to the Cromford Canal, built some 50 years previously. It is a Grade II* listed building.

Old Bess is an early beam engine built by the partnership of Boulton and Watt. The engine was constructed in 1777 and worked until 1848.

A cataract was a speed governing device used for early single-acting beam engines, particularly atmospheric engines and Cornish engines. It was a kind of water clock.

Resolution was an early beam engine, installed between 1781 and 1782 at Coalbrookdale as a water-returning engine to power the blast furnaces and ironworks there. It was one of the last water-returning engines to be constructed, before the rotative beam engine made this type of engine obsolete.

The Newcomen Memorial Engine is a preserved beam engine in Dartmouth, Devon. It was preserved as a memorial to Thomas Newcomen, inventor of the beam engine, who was born in Dartmouth.

The Grazebrook Engine is an 1817 beam engine that was used for blowing air over the hot coals of a blast furnace to increase the heat. It is now found as sentinel sculpture on the Dartmouth Circus roundabout at the entrance of the A38(M) in Birmingham, England. It is believed to be the largest steam engine used in Birmingham.