Related Research Articles

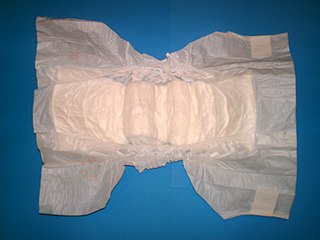

A diaper or a nappy is a type of underwear that allows the wearer to urinate or defecate without using a toilet, by absorbing or containing waste products to prevent soiling of outer clothing or the external environment. When diapers become wet or soiled, they require changing, generally by a second person such as a parent or caregiver. Failure to change a diaper on a sufficiently regular basis can result in skin problems around the area covered by the diaper.

Pulp is a fibrous lignocellulosic material prepared by chemically, semi-chemically or mechanically producing cellulosic fibers from wood, fiber crops, waste paper, or rags. Mixed with water and other chemicals or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other paper products.

Paperboard is a thick paper-based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker than paper and has certain superior attributes such as foldability and rigidity. According to ISO standards, paperboard is a paper with a grammage above 250 g/m2, but there are exceptions. Paperboard can be single- or multi-ply.

Pulpwood can be defined as timber that is ground and processed into a fibrous pulp. It is a versatile natural resource commonly used for paper-making but also made into low-grade wood and used for chips, energy, pellets, and engineered products.

Kenaf [etymology: Persian], Hibiscus cannabinus, is a plant in the family Malvaceae also called Deccan hemp and Java jute. Hibiscus cannabinus is in the genus Hibiscus and is native to Africa, though its exact origin is unknown. The name also applies to the fibre obtained from this plant. Kenaf is one of the allied fibres of jute and shows similar characteristics.

A menstrual pad, or simply a pad, is an absorbent item worn in the underwear when menstruating, bleeding after giving birth, recovering from gynecologic surgery, experiencing a miscarriage or abortion, or in any other situation where it is necessary to absorb a flow of blood from the vagina. A menstrual pad is a type of menstrual hygiene product that is worn externally, unlike tampons and menstrual cups, which are worn inside the vagina. Pads are generally changed by being stripped off the pants and panties, taking out the old pad, sticking the new one on the inside of the panties and pulling them back on. Pads are recommended to be changed every 3–4 hours to avoid certain bacteria that can fester in blood; this time also may differ depending on the kind worn, flow, and the time it is worn.

The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibres, the main component of paper. The kraft process involves treatment of wood chips with a hot mixture of water, sodium hydroxide (NaOH), and sodium sulfide (Na2S), known as white liquor, that breaks the bonds that link lignin, hemicellulose, and cellulose. The technology entails several steps, both mechanical and chemical. It is the dominant method for producing paper. In some situations, the process has been controversial because kraft plants can release odorous products and in some situations produce substantial liquid wastes.

Tissue paper or simply tissue is a lightweight paper or, light crêpe paper. Tissue can be made from recycled paper pulp on a paper machine.

A pulp mill is a manufacturing facility that converts wood chips or other plant fiber sources into a thick fiber board which can be shipped to a paper mill for further processing. Pulp can be manufactured using mechanical, semi-chemical, or fully chemical methods. The finished product may be either bleached or non-bleached, depending on the customer requirements.

Kraft paper or kraft is paper or paperboard (cardboard) produced from chemical pulp produced in the kraft process.

Nonwoven fabric or non-woven fabric is a fabric-like material made from staple fibre (short) and long fibres, bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt, which are neither woven nor knitted. Some non-woven materials lack sufficient strength unless densified or reinforced by a backing. In recent years, non-wovens have become an alternative to polyurethane foam.

A superabsorbent polymer (SAP) (also called slush powder) is a water-absorbing hydrophilic homopolymers or copolymers that can absorb and retain extremely large amounts of a liquid relative to its own mass.

Cotton paper, also known as rag paper or rag stock paper, is made using cotton linters or cotton from used cloth (rags) as the primary material. Prior to the mid-19th century, cotton paper was the main form of paper produced, with pulp paper replacing cotton paper as the main paper material during the 19th century. Although pulp paper was cheaper to produce, its quality and durability is significantly lower. Although pulp-paper quality improved significantly over the 20th century, cotton paper continues to be more durable, and consequently important documents are often printed on cotton paper. Different grades of cotton paper can be produced.

gDiapers are a hybrid diaper, so users can choose to use either a cloth insert or a disposable insert that can be flushed or composted. Co-founders are Jason and Kimberley Graham-Nye. gDiapers began being sold in 2004. gDiapers are licensed from Kuver Designs Pty Ltd, Tasmania, "Eenee designs" diapers.

Northern bleached softwood kraft (NBSK) is the paper industry's benchmark grade of pulp. Market NBSK is produced mainly in Canada and the Nordic countries. Some NBSK is also produced in north-western United States and in Russia. NBSK futures are traded on the Chicago Mercantile Exchange.

Expandable water toys are novelty items made from a superabsorbent polymer. They are toys that expand after putting them into water for anything between a few hours up to several days, depending on size. They shrink in saltwater or when exposed to air. They are made from polymers that can absorb and retain extremely large amounts of a liquid relative to their own mass.

Air-laid paper is a textile-like material categorized as a nonwoven fabric made from fluff pulp.

Southern bleached softwood kraft (SBSK) is a wood pulp mainly produced in the southern USA. The main raw materials are slash pine, longleaf pine, shortleaf pine, loblolly pine and virginia pine.

Mercerised pulp is a bleached pulp that is treated with hot diluted alkali to get extra high bulk and high porosity. The pulp feels and looks similar to a cotton ball.

Bleached Chemi-ThermoMechanical Pulp (BCTMP) is a pulp product used by the paper industry as a less-expensive alternative for Northern Bleached Softwood Kraft (NBSK).

References

- ↑ Nanko, Hirko; Button, Allan; Hillman, Dave (2005). The World of Market Pulp. Appleton, WI, USA: WOMP, LLC. p. 5. ISBN 0-615-13013-5.

- ↑ Moore, Dan. "Fibre Fundamentals - Fluff Pulp" (PDF). Retrieved 18 March 2013.[ permanent dead link ]

- ↑ Inside the Museum of Menstruation 6

- ↑ Nanko, Hirko; Button, Allan; Hillman, Dave (2005). The World of Market Pulp. Appleton, WI, USA: WOMP, LLC. p. 240. ISBN 0-615-13013-5.