A valve is a device or natural object that regulates, directs or controls the flow of a fluid by opening, closing, or partially obstructing various passageways. Valves are technically fittings, but are usually discussed as a separate category. In an open valve, fluid flows in a direction from higher pressure to lower pressure. The word is derived from the Latin valva, the moving part of a door, in turn from volvere, to turn, roll.

A railway air brake is a railway brake power braking system with compressed air as the operating medium. Modern trains rely upon a fail-safe air brake system that is based upon a design patented by George Westinghouse on April 13, 1869. The Westinghouse Air Brake Company was subsequently organized to manufacture and sell Westinghouse's invention. In various forms, it has been nearly universally adopted.

Pneumatics is a branch of engineering that makes use of gas or pressurized air.

An air compressor is a machine that takes ambient air from the surroundings and discharges it at a higher pressure. It is an application of a gas compressor and a pneumatic device that converts mechanical power into potential energy stored in compressed air, which has many uses. A common application is to compress air into a storage tank, for immediate or later use. When the delivery pressure reaches its set upper limit, the compressor is shut off, or the excess air is released through an overpressure valve. The compressed air is stored in the tank until it is needed. The pressure energy provided by the compressed air can be used for a variety of applications such as pneumatic tools as it is released. When tank pressure reaches its lower limit, the air compressor turns on again and re-pressurizes the tank. A compressor is different from a pump because it works on a gas, while pumps work on a liquid.

Lego Technic is a line of Lego interconnecting plastic rods and parts. The purpose of this series is to create advanced models of working vehicles and machines, compared to the simpler brick-building properties of normal Lego.

A hydrostatic test is a way in which pressure vessels such as pipelines, plumbing, gas cylinders, boilers and fuel tanks can be tested for strength and leaks. The test involves filling the vessel or pipe system with a liquid, usually water, which may be dyed to aid in visual leak detection, and pressurization of the vessel to the specified test pressure. Pressure tightness can be tested by shutting off the supply valve and observing whether there is a pressure loss. The location of a leak can be visually identified more easily if the water contains a colorant. Strength is usually tested by measuring permanent deformation of the container.

Fluid power is the use of fluids under pressure to generate, control, and transmit power. Fluid power is conventionally subdivided into hydraulics and pneumatics. Although steam is also a fluid, steam power is usually classified separately from fluid power. Compressed-air and water-pressure systems were once used to transmit power from a central source to industrial users over extended geographic areas; fluid power systems today are usually within a single building or mobile machine.

Hydropneumatic suspension is a type of motor vehicle suspension system, designed by Paul Magès, invented by Citroën, and fitted to Citroën cars, as well as being used under licence by other car manufacturers. Similar systems are also widely used on modern tanks and other large military vehicles. The suspension was referred to as Suspension oléopneumatique in early literature, pointing to oil and air as its main components.

For fluid power, a working fluid is a gas or liquid that primarily transfers force, motion, or mechanical energy. In hydraulics, water or hydraulic fluid transfers force between hydraulic components such as hydraulic pumps, hydraulic cylinders, and hydraulic motors that are assembled into hydraulic machinery, hydraulic drive systems, etc. In pneumatics, the working fluid is air or another gas which transfers force between pneumatic components such as compressors, vacuum pumps, pneumatic cylinders, and pneumatic motors. In pneumatic systems, the working gas also stores energy because it is compressible.

A hose is a flexible hollow tube designed to carry fluids from one location to another. Hoses are also sometimes called pipes, or more generally tubing. The shape of a hose is usually cylindrical.

Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses, tubes, or pipes.

This is a glossary of firefighting equipment.

Manifold vacuum, or engine vacuum in a petrol engine is the difference in air pressure between the engine's intake manifold and Earth's atmosphere.

Brake bleeding is the procedure performed on hydraulic brake systems whereby the brake lines are purged of any air bubbles. This is necessary because, while the brake fluid is an incompressible liquid, air bubbles are compressible gas and their presence in the brake system greatly reduces the hydraulic pressure that can be developed within the system. The same methods used for bleeding are also used for brake flushing or purging, where the old fluid is replaced with new fluid, which is necessary maintenance.

A hydraulic brake is an arrangement of braking mechanism which uses brake fluid, typically containing glycol ethers or diethylene glycol, to transfer pressure from the controlling mechanism to the braking mechanism.

A hydraulic cylinder is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke. It has many applications, notably in construction equipment, manufacturing machinery, elevators, and civil engineering. A hydraulic cylinder is a hydraulic actuator that provides linear motion when hydraulic energy is converted into mechanical movement. It can be likened to a muscle in that, when the hydraulic system of a machine is activated, the cylinder is responsible for providing the motion.

The Meillerwagen was a German World War II trailer used to transport a V-2 rocket from the 'transloading point' of the Technical Troop Area to the launching point, to erect the missile on the Brennstand, and to act as the service gantry for fuelling and launch preparation.

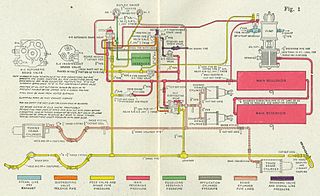

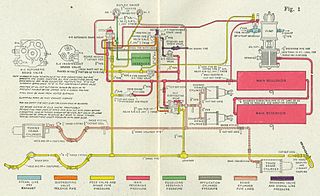

A pneumatic circuit is an interconnected set of components that convert compressed gas into mechanical work. In the normal sense of the term, the circuit must include a compressor or compressor-fed tank.

A booster pump is a machine which increases the pressure of a fluid. It may be used with liquids or gases, and the construction details vary depending on the fluid. A gas booster is similar to a gas compressor, but generally a simpler mechanism which often has only a single stage of compression, and is used to increase pressure of a gas already above ambient pressure. Two-stage boosters are also made. Boosters may be used for increasing gas pressure, transferring high pressure gas, charging gas cylinders and scavenging.