Related Research Articles

A container ship is a cargo ship that carries all of its load in truck-size intermodal containers, in a technique called containerization. Container ships are a common means of commercial intermodal freight transport and now carry most seagoing non-bulk cargo.

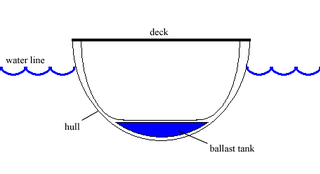

The waterline is the line where the hull of a ship meets the surface of the water. Specifically, it is also the name of a special marking, also known as an international load line, Plimsoll line and water line, that indicates the draft of the ship and the legal limit to which a ship may be loaded for specific water types and temperatures in order to safely maintain buoyancy, particularly with regard to the hazard of waves that may arise. Varying water temperatures will affect a ship's draft, because warm water is less dense than cold water, providing less buoyancy. In the same way, fresh water is less dense than salinated or seawater with a similar lessening effect upon buoyancy.

A ballast tank is a compartment within a boat, ship or other floating structure that holds water, which is used as ballast to provide hydrostatic stability for a vessel, to reduce or control buoyancy, as in a submarine, to correct trim or list, to provide a more even load distribution along the hull to reduce structural hogging or sagging stresses, or to increase draft, as in a semi-submersible vessel or platform, or a SWATH, to improve seakeeping. Using water in a tank provides easier weight adjustment than the stone or iron ballast used in older vessels, and makes it easy for the crew to reduce a vessel's draft when it enters shallower water, by temporarily pumping out ballast. Airships use ballast tanks mainly to control buoyancy and correct trim.

The International Association of Classification Societies (IACS) is a technically based non-governmental organization that currently consists of twelve member marine classification societies. More than 90% of the world's cargo-carrying ships’ tonnage is covered by the classification standards set by member societies of IACS.

The National Cargo Bureau (NCB) a not-for-profit marine surveying organization charged with assisting the U.S. Coast Guard with carrying out the provisions of the International Convention for the Safety of Life at Sea. The NCB was formed by a group of marine underwriters and the Coast Guard for the purpose of reducing losses of grain ships. Any ship loading grain in the US sailing for a foreign port must have a certificate issued by the NCB in order to sail( See U.S. Coast Guard Navigation and Vessel Inspection Circular No. 5-94 - NVIC 05-94 ). The NCB acts with and enforces the regulations of the Coast Guard in this area. Grain ships have unique stability issues and are prone to capsize if loaded improperly. Headquartered in New York City, the NCB has offices throughout United States.

The stability conditions of watercraft are the various standard loading configurations to which a ship, boat, or offshore platform may be subjected. They are recognized by classification societies such as Det Norske Veritas, Lloyd's Register and American Bureau of Shipping (ABS). Classification societies follow rules and guidelines laid down by International Convention for the Safety of Life at Sea (SOLAS) conventions, the International Maritime Organization and laws of the country under which the vessel is flagged, such as the Code of Federal Regulations.

Ice class refers to a notation assigned by a classification society or a national authority to denote the additional level of strengthening as well as other arrangements that enable a ship to navigate through sea ice. Some ice classes also have requirements for the ice-going performance of the vessel.

Ship stability is an area of naval architecture and ship design that deals with how a ship behaves at sea, both in still water and in waves, whether intact or damaged. Stability calculations focus on centers of gravity, centers of buoyancy, the metacenters of vessels, and on how these interact.

A heavy-lift ship is a vessel designed to move very large loads that cannot be handled by normal ships. They are of two types:

In nautical terminology, stowage is the amount of room available for stowing materials aboard a ship, tank or an airplane.

Polar Class (PC) refers to the ice class assigned to a ship by a classification society based on the Unified Requirements for Polar Class Ships developed by the International Association of Classification Societies (IACS). Seven Polar Classes are defined in the rules, ranging from PC 1 for year-round operation in all polar waters to PC 7 for summer and autumn operation in thin first-year ice.

NYK Vega is a container ship, operated by Nippon Yusen Ship Management. The vessel has a capacity of 8,600 containers in company calculations and 9,012 TEU in International Maritime Organization calculations. The difference comes from the use of a different method of stowing in checking the ship's stability.

CargoMax is a stability and load management software application for marine and offshore industries. It is developed and sold by Herbert-ABS Software Solutions, LLC. First released in 1979, CargoMax was one of the first computerized systems for planning and evaluating ship loading; it is currently one of the most-used software applications for this purpose. It helps determine cargo loading sequences by calculating stability and stress based on ship models created from vessel data: lightship weights, hydrostatic characteristics, tank data, and allowable shear forces and bending moments. Naval architects and engineers from Herbert-ABS customize each CargoMax installation using shipyard drawings and technical data. Different installations also include different sets of features from the program.

Ship management is the activity of managing marine vessels. The vessels under management could be owned by a sister concern of the ship management company or by independent vessel owners. A vessel owning company that generally has several vessels in its fleet, entrusts the fleet management to a single or multiple ship management companies. Ship management is often entrusted to third parties due to the various hassles that are involved in managing a ship. For instance, ships could be considered as large factories that travel across seas under various weather conditions for several days at a stretch. These vessels are equipped with several types of machinery that require appropriate maintenance and the associated spares on board. In the scenario of a vessel lacking adequate maintenance, this could lead to the breakdown of the equipment in the middle of a voyage at sea. A breakdown could be an expensive affair. A second scenario would be – a vessel is continuously on the move or under some sort of activity and hence requires a competent crew. The documents of the crew need to comply with international regulations, their transportation to and from the vessel must be arranged for, their competencies must align with the requirement of the vessel and must complement the skillsets of the existing onboard crew. Hence several parameters must be considered which is a tedious job.

Sesam is a software suite for structural and hydrodynamic analysis of ships and offshore structures. It is based on the displacement formulation of the Finite Element Method.

Vessel safety surveys are inspections of the structure and equipment of a vessel to assess the condition of the surveyed items and check that they comply with legal or classification society requirements for insurance and registration. They may occur at any time when there is reason to suspect that the condition has changed significantly since the previous survey, and the first survey is generally during construction or before first registration. The criteria for acceptance are defined by the licensing or registration authority for a variety of equipment vital to the safe operation of the vessel, such as safety equipment, lifting equipment, hull structure, static stability, ground tackle, propulsion machinery, auxiliary machinery, etc. The SOLAS Convention, specifies safety equipment for commercial vessels operating internationally.

The FORAN system is an integrated CAD/CAM/CAE system developed by SENER for the design and production of practically any naval ship and offshore unit. It is a multidisciplinary and integrated system that can be used in all the ship design and production phases and disciplines. The System collects all the information in a single database. FORAN is mainly focused on the design of:

Load shifting is a dangerous phenomenon in water, air, and ground transportation where cargo shifts in a cargo vehicle. This causes the vehicle to tilt, which causes even more movement of the cargo, and further tilting, thereby creating a positive feedback loop. If not corrected, this will lead to severe tipping or even capsizing. Such a dangerous occurrence is prevented by active load management, avoiding high sea conditions for ships, and proper container/bulkhead design.

SDC Verifier is a commercial finite element analysis post-processor software with a calculation core for checking structures according to different standards, either predefined or self programmed, and final report generation with all checks. The goal is to automate routine work and speed up a verification of the engineering projects. It works as an addon for popular FEA software Ansys, Femap and Simcenter 3D.

Stowage plan for container ships or bay plan is the plan and method by which different types of container vessels are loaded with containers of specific standard sizes. The plans are used to maximize the economy of shipping and safety on board.

References

- ↑ "Navis MACS3 loading computer". Navis.

- 1 2 "ISO 16155:2006 - Ships and marine technology -- Computer applications -- Shipboard loading instruments".

- ↑ "DNV-CG-0053 : Approval and certification of the software of loading computer systems". DNV.

- ↑ "ABS Guidance Notes for the Application of Ergonomics to Marine Systems" (PDF). ABS.

- ↑ "BV Rules for the Classification of Steel Ships, Pt C, Ch 3, Sec 3 "COMPUTER BASED SYSTEMS"" (PDF).

- ↑ "IACS Recommendation on Loading Instruments (No 48)" (PDF).

- ↑ "IACS Unified Requirements (E27) - Cyber resilience of on-board systems and equipment" (PDF).

- ↑ "SMDG recommendations". SMDG.

- ↑ "Load List and Bay Plan". DCSA.

- ↑ "MACS3/StowMAN additional modules and programs".