A loom is a device used to weave cloth and tapestry. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. The precise shape of the loom and its mechanics may vary, but the basic function is the same.

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft, woof, or filling. The method in which these threads are interwoven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds the warp threads in place while filling threads are woven through them. A fabric band that meets this definition of cloth can also be made using other methods, including tablet weaving, back strap loom, or other techniques that can be done without looms.

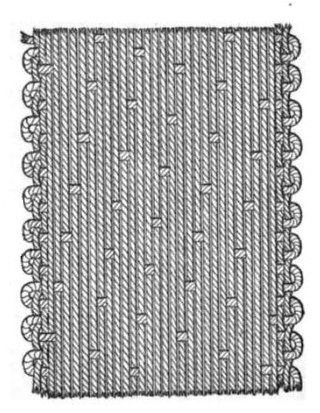

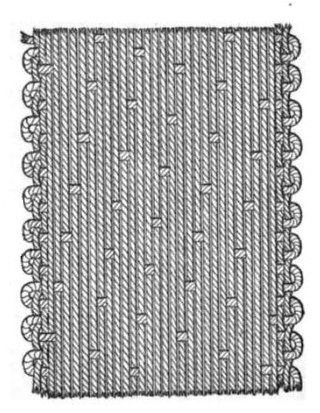

Drawn thread work is one of the earliest forms of open work embroidery, and has been worked throughout Europe. Originally it was often used for ecclesiastical items and to ornament shrouds. It is a form of counted-thread embroidery based on removing threads from the warp and/or the weft of a piece of even-weave fabric. The remaining threads are grouped or bundled together into a variety of patterns. The more elaborate styles of drawn thread work use a variety of other stitches and techniques, but the drawn thread parts are their most distinctive element. It is also grouped with whitework embroidery because it was traditionally done in white thread on white fabric and is often combined with other whitework techniques.

Woven fabric is any textile formed by weaving. Woven fabrics are often created on a loom, and made of many threads woven on a warp and a weft. Technically, a woven fabric is any fabric made by interlacing two or more threads at right angles to one another. Woven fabrics can be made of natural fibers, synthetic fibers, or a mixture of both, such as cotton and polyester.

A satin weave is a type of fabric weave that produces a characteristically glossy, smooth or lustrous material, typically with a glossy top surface and a dull back; it is not durable, as it tends to snag. It is one of three fundamental types of textile weaves alongside plain weave and twill weave.

Ikat is a dyeing technique from Indonesia used to pattern textiles that employs resist dyeing on the yarns prior to dyeing and weaving the fabric. The term is also used to refer to related and unrelated traditions in other cultures. In Southeast Asia, where it is the most widespread, ikat weaving traditions can be divided into two general clades. The first is found among Daic-speaking peoples. The second, larger group is found among the Austronesian peoples and spread via the Austronesian expansion. Similar dyeing and weaving techniques that developed independently are also present in other regions of the world, including India, Central Asia, Japan, Africa, and the Americas.

A kilim is a flat tapestry-woven carpet or rug traditionally produced in countries of the former Persian Empire, including Iran, the Balkans and the Turkic countries. Kilims can be purely decorative or can function as prayer rugs. Modern kilims are popular floor coverings in Western households.

Damask is a reversible patterned fabric of silk, wool, linen, cotton, or synthetic fibers, with a pattern formed by weaving. Damasks are woven with one warp yarn and one weft yarn, usually with the pattern in warp-faced satin weave and the ground in weft-faced or sateen weave. Twill damasks include a twill-woven ground or pattern.

Double cloth or double weave is a kind of woven textile in which two or more sets of warps and one or more sets of weft or filling yarns are interconnected to form a two-layered cloth. The movement of threads between the layers allows complex patterns and surface textures to be created.

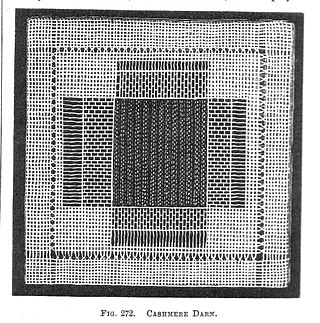

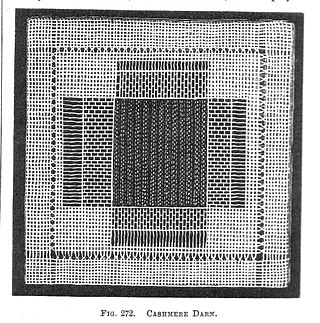

Darning is a sewing technique for repairing holes or worn areas in fabric or knitting using needle and thread alone. It is often done by hand, but using a sewing machine is also possible. Hand darning employs the darning stitch, a simple running stitch in which the thread is "woven" in rows along the grain of the fabric, with the stitcher reversing direction at the end of each row, and then filling in the framework thus created, as if weaving. Darning is a traditional method for repairing fabric damage or holes that do not run along a seam, and where patching is impractical or would create discomfort for the wearer, such as on the heel of a sock.

For woven textiles, grain refers to the orientation of the weft and warp threads. The three named grains are straight grain, cross grain, and the bias grain. In sewing, a pattern piece can be cut from fabric in any orientation, and the chosen grain or orientation will affect the way the fabric hangs and stretches and thus the fit of a garment. Generally speaking a piece is said to be cut on a particular grain when the longest part of the pattern or the main seams of the finished piece are aligned with that grain. Non-woven materials such as felt, interfacing or leather do not have a grain.

Kasuri (絣) is the Japanese term for fabric that has been woven with fibers dyed specifically to create patterns and images in the fabric, typically referring to fabrics produced within Japan using this technique. It is a form of ikat dyeing, traditionally resulting in patterns characterized by their blurred or brushed appearance.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, which turns yarn into cloth. The machine used for weaving is the loom. For decoration, the process of colouring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

Band weaving refers to the hand production of narrow woven fabric. This fabric may be called tape, band, inkle, strap, belt, back strap, trim, and more. It can be accomplished on a variety of types of looms, including inkle, band, tape, backstrap, and rigid heddle looms. Hole and slot heddles are also designed to weave bands. Depending on which loom is used, the material could be warp-faced or a balanced weave.

Waffle fabric, also known as honeycomb fabric, has raised threads that form small rectangles. It can be made by either weaving or knitting. Waffle weave is a further exploitation of plain weave and twill weave which produces a three-dimensional effect. The combination of warp and weft floats creates the structure. It is woven partly on tabby areas surrounded by ridges of long floats. The weave consists of warp and weft floats arranged around a plain weave center. The warp and weft threads are interlaced and floating in a way that creates small square ridges and hollows in the fabric in a regular pattern.

Soumak is a tapestry technique of weaving sturdy, decorative fabrics used for carpets, rugs, domestic bags and bedding, with soumak fabrics used for bedding known as soumak mafrash.

Leno weave is a weave in which two warp yarns are woven around the weft yarns to provide a strong yet sheer fabric. The standard warp yarn is paired with a skeleton or 'doup' yarn; these twisted warp yarns grip tightly to the weft which causes the durability of the fabric. Leno weave produces an open fabric with almost no yarn slippage or misplacement of threads.

Venkatagiri Sari is a sari style woven in Venkatagiri of Tirupati district in the Indian state of Andhra Pradesh. It was registered as one of the geographical indication from Andhra Pradesh by Geographical Indications of Goods Act, 1999. Venkatagiri saris are known for their fine weaving. These style of saris can also be found in the villages of Sengunthapuram, Variyankaval, Elaiyur, Kallathur, Andimadam and Marudhur villages.

Mangalagiri Sarees and Fabrics are produced by performing handicraft weaving in Mangalagiri, a town in Guntur district of the Indian state of Andhra Pradesh. It was registered as one of the handicraft in the geographical indication from Andhra Pradesh by Geographical Indications of Goods Act, 1999.

Pin weaving is a form of small-scale weaving traditionally done on a frame made of pins; the warp and weft are wrapped around the pins. Pin-woven textiles have a selvage edge all the way around.