A loom is a device used to weave cloth and tapestry. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. The precise shape of the loom and its mechanics may vary, but the basic function is the same.

Woven fabric is any textile formed by weaving. Woven fabrics are often created on a loom, and made of many threads woven on a warp and a weft. Technically, a woven fabric is any fabric made by interlacing two or more threads at right angles to one another. Woven fabrics can be made of natural fibers, synthetic fibers, or a mixture of both, such as cotton and polyester.

A satin weave is a type of fabric weave that produces a characteristically glossy, smooth or lustrous material, typically with a glossy top surface and a dull back; it is not durable, as it tends to snag. It is one of three fundamental types of textile weaves alongside plain weave and twill weave.

Twill is a type of textile weave with a pattern of diagonal parallel ribs. It is one of three fundamental types of weave, along with plain weave and satin. It is made by passing the weft thread over one or more warp threads then under two or more warp threads and so on, with a "step", or offset, between rows to create the characteristic diagonal pattern. Because of this structure, twill generally drapes well.

Ikat is a dyeing technique from Southeast Asia used to pattern textiles that employs resist dyeing on the yarns prior to dyeing and weaving the fabric. In Southeast Asia, where it is the most widespread, ikat weaving traditions can be divided into two general groups of related traditions. The first is found among Daic-speaking peoples. The second, larger group is found among the Austronesian peoples and spread via the Austronesian expansion to as far as Madagascar. It is most prominently associated with the textile traditions of Indonesia in modern times, from where the term ikat originates. Similar unrelated dyeing and weaving techniques that developed independently are also present in other regions of the world, including India, Central Asia, Japan, Africa, and the Americas.

Crêpe, also spelled crepe or crape, is a silk, wool, or synthetic fiber fabric with a distinctively crisp and crimped appearance. The term "crape" typically refers to a form of the fabric associated specifically with mourning. Crêpe was also historically called "crespe" or "crisp".

Textile manufacturing or textile engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products.

Paithani is a variety of sari, named after the Paithan town in [[Aurangabad district, Maharashtra|] from state of Maharashtra in India where the sari was first made by hand. Present day Yeola town in Nashik, Maharashtra is the largest manufacturer of Paithani.

Kasuri (絣) is the Japanese term for fabric that has been woven with fibers dyed specifically to create patterns and images in the fabric, typically referring to fabrics produced within Japan using this technique. It is a form of ikat dyeing, traditionally resulting in patterns characterized by their blurred or brushed appearance.

Plain weave is the most basic of three fundamental types of textile weaves. It is strong and hard-wearing, and is used for fashion and furnishing fabrics. Fabrics with a plain weave are generally strong, durable, and have a smooth surface. They are often used for a variety of applications, including clothing, home textiles, and industrial fabrics.

A selvage or selvedge is a "self-finished" edge of a piece of fabric which keeps it from unraveling and fraying. The term "self-finished" means that the edge does not require additional finishing work, such as hem or bias tape, to prevent fraying.

In India, about 97% of the raw mulberry silk is produced in the Indian states of Karnataka, Andhra Pradesh, Tamil Nadu and West Bengal. Mysore and North Bangalore, the upcoming site of a US$20 million "Silk City", contribute to a majority of silk production. Another emerging silk producer is Tamil Nadu in the place in where mulberry cultivation is concentrated in Salem, Erode and Dharmapuri districts. Hyderabad, Andhra Pradesh and Gobichettipalayam, Tamil Nadu were the first locations to have automated silk reeling units.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, which turns it into cloth. The machine used for weaving is the loom. For decoration, the process of colouring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

Textile fibers, threads, yarns and fabrics are measured in a multiplicity of units.

In weaving, the shed is the temporary separation between upper and lower warp yarns through which the weft is woven. The shed is created to make it easy to interlace the weft into the warp and thus create woven fabric. Most types of looms have some sort of device which separates some of the warp threads from the others. This separation is called the shed, and allows for a shuttle carrying the weft thread to move through the shed perpendicular to the warp threads. Which threads are raised and which are lowered are changed after each pass of the shuttle.

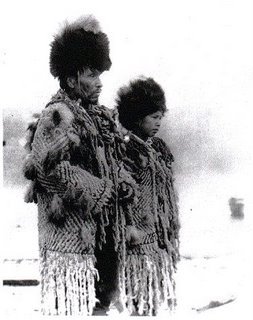

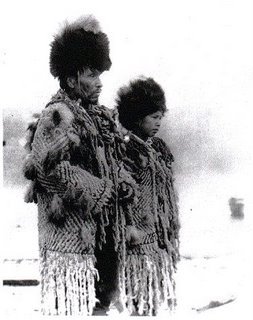

Salish are skilled weavers and knitters of the Pacific Northwest. They are most noted for their beautiful twill blankets many of which are very old. The adoption of new fabrics, dyes, and weaving techniques allow us to study a wide variety of Salish weavings today.

Dupioni is a plain weave silk fabric, produced using fine yarn in the warp and uneven yarn reeled from two or more entangled cocoons in the weft. This creates tightly woven yardage with a highly-lustrous surface and a crisp hand. It is similar to shantung, but slightly thicker, heavier, and with a greater slub count. In Japan a cocoon containing more than one silkworm is called tamamayu.

Soumak is a tapestry technique of weaving sturdy, decorative fabrics used for carpets, rugs, domestic bags and bedding, with soumak fabrics used for bedding known as soumak mafrash.

Bhutanese textiles represent a rich and complex repository of a unique art form. They are recognised for their abundance of colour, sophistication and variation of patterns, and the intricate dyeing and weaving techniques. The weavers, who are mostly women, must not be seen merely as creators of wealth but also as the innovators and owners of artistic skills developed and nurtured over centuries of time.

The swivel weave is a weaving technique that incorporates a decorative element into the fabric by using small shuttles that insert additional weft thread around selected warp threads, while the main weft thread forms the fabric's structure. This method differs from the plain weave, which lacks this decorative aspect.