Related Research Articles

Stained glass is colored glass as a material or works created from it. Although, it is traditionally made in flat panels and used as windows, the creations of modern stained glass artists also include three-dimensional structures and sculpture. Modern vernacular usage has often extended the term "stained glass" to include domestic lead light and objets d'art created from foil glasswork exemplified in the famous lamps of Louis Comfort Tiffany.

Metalworking is the process of shaping and reshaping metals in order to create useful objects, parts, assemblies, and large scale structures. As a term, it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges, down to precise engine parts and delicate jewelry.

Glassblowing is a glassforming technique that involves inflating molten glass into a bubble with the aid of a blowpipe. A person who blows glass is called a glassblower, glassmith, or gaffer. A lampworker manipulates glass with the use of a torch on a smaller scale, such as in producing precision laboratory glassware out of borosilicate glass.

Float glass is a sheet of glass made by floating molten glass on a bed of molten metal of a low melting point, typically tin, although lead was used for the process in the past. This method gives the sheet uniform thickness and a very flat surface. The float glass process is also known as the Pilkington process, named after the British glass manufacturer Pilkington, which pioneered the technique in the 1950s at their production site in St Helens, Merseyside.

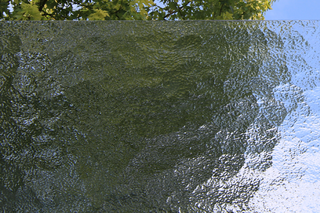

Cathedral glass is the name given commercially to monochromatic sheet glass. It is thin by comparison with 'slab glass', may be coloured, and is textured on one side. The name draws from the fact that windows of stained glass were a feature of medieval European cathedrals from the 10th century onward.

Glass tubes are mainly cylindrical hollow-wares. Their special shape combined with the huge variety of glass types, allows the use of glass tubing in many applications. For example, laboratory glassware, lighting applications, solar thermal systems and pharmaceutical packaging to name the largest.

Glass bead making has long traditions, with the oldest known beads dating over 3,000 years. Glass beads have been dated back to at least Roman times. Perhaps the earliest glass-like beads were Egyptian faience beads, a form of clay bead with a self-forming vitreous coating. Glass beads are significant in archaeology because the presence of glass beads often indicate that there was trade and that the bead making technology was being spread. In addition, the composition of the glass beads could be analyzed and help archaeologists understand the sources of the beads.

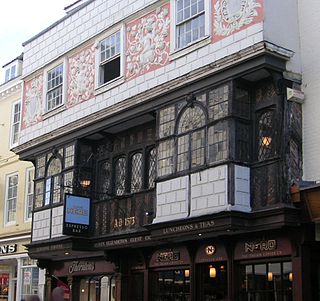

Blown plate is a hand-blown glass. There is a record of blown plate being produced in London in 1620.

Broad sheet is a type of hand-blown glass. It was first made in Sussex in 1226.

Cylinder blown sheet is a type of hand-blown window glass. It is created with a similar process to broad sheet, but with the use of larger cylinders. In this manufacturing process glass is blown into a cylindrical iron mold. The ends are cut off and a cut is made down the side of the cylinder. The cut cylinder is then placed in an oven where the cylinder unrolls into a flat glass sheet. William J. Blenko used this method in the early 1900s to make stained glass. The result is much larger panes and improved surface quality over broad sheet, although still containing some imperfections. These imperfect panes have led to the misconception that glass is actually a high-viscosity fluid at room temperature, which is not the case.

Machine drawn cylinder sheet was the first mechanical method for "drawing" window glass. Cylinders of glass 40 feet (12 m) high are drawn vertically from a circular tank. The glass is then annealed and cut into 7 to 10 foot cylinders. These are cut lengthways, reheated, and flattened.

Crown glass was an early type of window glass. In this process, glass was blown into a "crown" or hollow globe. This was then transferred from the blowpipe to a punty and then flattened by reheating and spinning out the bowl-shaped piece of glass (bullion) into a flat disk by centrifugal force, up to 5 or 6 feet in diameter. The glass was then cut to the size required.

Architectural glass is glass that is used as a building material. It is most typically used as transparent glazing material in the building envelope, including windows in the external walls. Glass is also used for internal partitions and as an architectural feature. When used in buildings, glass is often of a safety type, which include reinforced, toughened and laminated glasses.

Gear cutting is any machining process for creating a gear. The most common gear-cutting processes include hobbing, broaching, milling, grinding, and skiving. Such cutting operations may occur either after or instead of forming processes such as forging, extruding, investment casting, or sand casting.

Plate glass, flat glass or sheet glass is a type of glass, initially produced in plane form, commonly used for windows, glass doors, transparent walls, and windscreens. For modern architectural and automotive applications, the flat glass is sometimes bent after production of the plane sheet. Flat glass stands in contrast to container glass and glass fibre.

Grinding is a type of abrasive machining process which uses a grinding wheel as cutting tool.

Centrifugal casting or rotocasting is a casting technique that is typically used to cast thin-walled cylinders. It is typically used to cast materials such as metals, glass, and concrete. A high quality is attainable by control of metallurgy and crystal structure. Unlike most other casting techniques, centrifugal casting is chiefly used to manufacture rotationally symmetric stock materials in standard sizes for further machining, rather than shaped parts tailored to a particular end-use.

The history of glass-making dates back to at least 3,600 years ago in Mesopotamia. However, most writers claim that they may have been producing copies of glass objects from Egypt. Other archaeological evidence suggests that the first true glass was made in coastal north Syria, Mesopotamia or Egypt. The earliest known glass objects, of the mid 2,000 BCE, were beads, perhaps initially created as the accidental by-products of metal-working (slags) or during the production of faience, a pre-glass vitreous material made by a process similar to glazing. Glass products remained a luxury until the disasters that overtook the late Bronze Age civilizations seemingly brought glass-making to a halt.

Glazing, which derives from the Middle English for 'glass', is a part of a wall or window, made of glass. Glazing also describes the work done by a professional "glazier". Glazing is also less commonly used to describe the insertion of ophthalmic lenses into an eyeglass frame.

19th century glass categories in the United States include types of glass and decoration methods for glass. A simplified category version appropriate at the beginning of the century is glassware, bottles, and windows. As the century progressed, glass production became more complex and made necessary more categories and subcategories. An 1884 United States government report used glassware, bottles, windows, and plate glass as major categories—although plate glass accounted for only four percent of the value of all glass made.

References

- ↑ "Hand-blown glass: manufacturing process". London Crown Glass Company. Archived from the original on November 6, 2005. Retrieved December 30, 2005.

- ↑ Encyclopædia Britannica 11th edition (1911)