For motorized vehicles, such as automobiles, aircraft, and watercraft, vehicle dynamics is the study of vehicle motion, e.g., how a vehicle's forward movement changes in response to driver inputs, propulsion system outputs, ambient conditions, air/surface/water conditions, etc.

The MacPherson strut is a type of automotive suspension system that uses the top of a telescopic damper as the upper steering pivot. It is widely used in the front suspension of modern vehicles, and is named for American automotive engineer Earle S. MacPherson, who invented and developed the design.

A torsion bar suspension, also known as a torsion spring suspension, is any vehicle suspension that uses a torsion bar as its main weight-bearing spring. One end of a long metal bar is attached firmly to the vehicle chassis; the opposite end terminates in a lever, the torsion key, mounted perpendicular to the bar, that is attached to a suspension arm, a spindle, or the axle. Vertical motion of the wheel causes the bar to twist around its axis and is resisted by the bar's torsion resistance. The effective spring rate of the bar is determined by its length, cross section, shape, material, and manufacturing process.

Suspension is the system of tires, tire air, springs, shock absorbers and linkages that connects a vehicle to its wheels and allows relative motion between the two. Suspension systems must support both road holding/handling and ride quality, which are at odds with each other. The tuning of suspensions involves finding the right compromise. It is important for the suspension to keep the road wheel in contact with the road surface as much as possible, because all the road or ground forces acting on the vehicle do so through the contact patches of the tires. The suspension also protects the vehicle itself and any cargo or luggage from damage and wear. The design of front and rear suspension of a car may be different.

In vehicle dynamics, slip angle or sideslip angle is the angle between the direction in which a wheel is pointing and the direction in which it is actually traveling. This slip angle results in a force, the cornering force, which is in the plane of the contact patch and perpendicular to the intersection of the contact patch and the midplane of the wheel. This cornering force increases approximately linearly for the first few degrees of slip angle, then increases non-linearly to a maximum before beginning to decrease.

Understeer and oversteer are vehicle dynamics terms used to describe the sensitivity of a vehicle to steering. Oversteer is what occurs when a car turns (steers) by more than the amount commanded by the driver. Conversely, understeer is what occurs when a car steers less than the amount commanded by the driver.

Automobile handling and vehicle handling are descriptions of the way a wheeled vehicle responds and reacts to the inputs of a driver, as well as how it moves along a track or road. It is commonly judged by how a vehicle performs particularly during cornering, acceleration, and braking as well as on the vehicle's directional stability when moving in steady state condition.

Weight transfer and load transfer are two expressions used somewhat confusingly to describe two distinct effects:

A double wishbone suspension is an independent suspension design for automobiles using two wishbone-shaped arms to locate the wheel. Each wishbone or arm has two mounting points to the chassis and one joint at the knuckle. The shock absorber and coil spring mount to the wishbones to control vertical movement. Double wishbone designs allow the engineer to carefully control the motion of the wheel throughout suspension travel, controlling such parameters as camber angle, caster angle, toe pattern, roll center height, scrub radius, scuff and more.

A swing axle is a simple type of independent suspension designed and patented by Edmund Rumpler in 1903. This was a revolutionary invention in automotive suspension, allowing driven (powered) wheels to follow uneven road surfaces independently, thus enabling the vehicle's wheels to maintain better road contact and holding; plus each wheel's reduced unsprung weight means their movements have less impact on the vehicle as a whole. The first automotive application was the Rumpler Tropfenwagen, later followed by the Mercedes 130H/150H/170H, the Standard Superior, the Volkswagen Beetle and its derivatives, the Chevrolet Corvair, and the roll-over prone M151 jeep amongst others.

An anti-roll bar is a part of many automobile suspensions that helps reduce the body roll of a vehicle during fast cornering or over road irregularities. It connects opposite (left/right) wheels together through short lever arms linked by a torsion spring. A sway bar increases the suspension's roll stiffness—its resistance to roll in turns—independent of its spring rate in the vertical direction. The first stabilizer bar patent was awarded to Canadian inventor Stephen Coleman of Fredericton, New Brunswick on April 22, 1919.

A beam axle, rigid axle or solid axle is a dependent suspension design in which a set of wheels is connected laterally by a single beam or shaft. Beam axles were once commonly used at the rear wheels of a vehicle, but historically they have also been used as front axles in four-wheel-drive vehicles. In most automobiles, beam axles have been replaced with front and rear independent suspensions.

In an automobile, ball joints are spherical bearings that connect the control arms to the steering knuckles, and are used on virtually every automobile made. They bionically resemble the ball-and-socket joints found in most tetrapod animals.

A Corvette leaf spring is a type of independent suspension that utilizes a fiber-reinforced plastic (FRP) mono-leaf spring instead of more conventional coil springs. It is named after the Chevrolet Corvette, the American sports car for which it was originally developed and first utilized. A notable characteristic of this suspension configuration is the mounting of the mono-leaf spring such that it can serve as both ride spring and anti-roll spring. In contrast to many applications of leaf springs in automotive suspension designs, this type does not use the spring as a locating link. While this suspension type is most notably associated with several generations of the Chevrolet Corvette the design has been used in other production General Motors cars, as well as vehicles from Volvo Cars and Mercedes-Benz Sprinter van. Fiat produced cars with a similar configuration, using a multi-leaf steel spring in place of the FRP mono-leaf spring.

Bicycle and motorcycle dynamics is the science of the motion of bicycles and motorcycles and their components, due to the forces acting on them. Dynamics falls under a branch of physics known as classical mechanics. Bike motions of interest include balancing, steering, braking, accelerating, suspension activation, and vibration. The study of these motions began in the late 19th century and continues today.

Automotive suspension design is an aspect of automotive engineering, concerned with designing the suspension for cars and trucks. Suspension design for other vehicles is similar, though the process may not be as well established.

The twist-beam rear suspension is a type of automobile suspension based on a large H or C-shaped member. The front of the H attaches to the body via rubber bushings, and the rear of the H carries each stub-axle assembly, on each side of the car. The cross beam of the H holds the two trailing arms together, and provides the roll stiffness of the suspension, by twisting as the two trailing arms move vertically, relative to each other.

Tire balance, also called tire unbalance or tire imbalance, describes the distribution of mass within an automobile tire or the entire wheel on which it is mounted.

The 7 post shaker is a piece of test equipment used to perform technical analysis on race cars. By applying shaking forces the shaker can emulate banking loads, lateral load transfer, longitudinal weight transfer and ride height sensitive downforce to emulate specific racetracks.

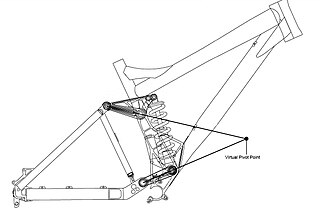

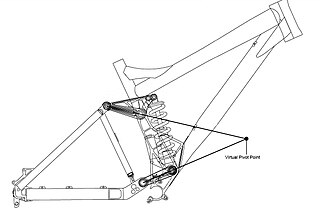

The DW-link is a subset of the common four-bar system used widely in bicycle suspension. The four-bar system has been used on mountain bikes since the early days of suspension. Similar suspension systems to the DW-link have been used by Schwinn, Fisher and Karpiel. Currently a similar system is used by Giant and named "Maestro". DW-link gets its name from the designer and patent holder, mechanical engineer Dave Weagle. Currently the DW-link has been licensed to the following bicycle companies: PIVOT Cycles, Ibis, Independent Fabrication, Turner Suspension Bicycles, and Iron Horse Bicycles. The DW-link suspension design was used to win six Elite level UCI downhill World Championships from 2005 to 2007, the highest contested level of the sport. This winning streak made the dw-link the most successful linkage suspension platform in the history of the sport of downhill. Dave Weagle also developed the Split Pivot suspension and Delta System which are both used in cycling.