The MacPherson strut is a type of automotive suspension system that uses the top of a telescopic damper as the upper steering pivot. It is widely used in the front suspension of modern vehicles. The name comes from American automotive engineer Earle S. MacPherson, who invented and developed the design.

A strut is a structural component commonly found in engineering, aeronautics, architecture and anatomy. Struts generally work by resisting longitudinal compression, but they may also serve in tension.

A torsion bar suspension, also known as a torsion spring suspension, is any vehicle suspension that uses a torsion bar as its main weight-bearing spring. One end of a long metal bar is attached firmly to the vehicle chassis; the opposite end terminates in a lever, the torsion key, mounted perpendicular to the bar, that is attached to a suspension arm, a spindle, or the axle. Vertical motion of the wheel causes the bar to twist around its axis and is resisted by the bar's torsion resistance. The effective spring rate of the bar is determined by its length, cross section, shape, material, and manufacturing process.

Suspension is the system of tires, tire air, springs, shock absorbers and linkages that connects a vehicle to its wheels and allows relative motion between the two. Suspension systems must support both road holding/handling and ride quality, which are at odds with each other. The tuning of suspensions involves finding the right compromise. It is important for the suspension to keep the road wheel in contact with the road surface as much as possible, because all the road or ground forces acting on the vehicle do so through the contact patches of the tires. The suspension also protects the vehicle itself and any cargo or luggage from damage and wear. The design of front and rear suspension of a car may be different.

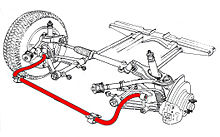

Independent suspension is any automobile suspension system that allows each wheel on the same axle to move vertically independently of the others. This is contrasted with a beam axle or deDion axle system in which the wheels are linked. "Independent" refers to the motion or path of movement of the wheels or suspension. It is common for the left and right sides of the suspension to be connected with anti-roll bars or other such mechanisms. The anti-roll bar ties the left and right suspension spring rates together but does not tie their motion together.

Automobile handling and vehicle handling are descriptions of the way a wheeled vehicle responds and reacts to the inputs of a driver, as well as how it moves along a track or road. It is commonly judged by how a vehicle performs particularly during cornering, acceleration, and braking as well as on the vehicle's directional stability when moving in steady state condition.

A double wishbone suspension is an independent suspension design for automobiles using two wishbone-shaped arms to locate the wheel. Each wishbone or arm has two mounting points to the chassis and one joint at the knuckle. The shock absorber and coil spring mount to the wishbones to control vertical movement. Double wishbone designs allow the engineer to carefully control the motion of the wheel throughout suspension travel, controlling such parameters as camber angle, caster angle, toe pattern, roll center height, scrub radius, scuff, and more.

The Chapman strut is a design of independent rear suspension used for light cars, particularly sports and racing cars. It takes its name from, and is best known for its use by, Colin Chapman of Lotus.

A swing axle is a simple type of independent suspension designed and patented by Edmund Rumpler in 1903 for the rear axle of rear wheel drive vehicles. This was a revolutionary invention in automotive suspension, allowing driven (powered) wheels to follow uneven road surfaces independently, thus enabling the vehicle's wheels to maintain better road contact and holding; plus each wheel's reduced unsprung weight means their movements have less impact on the vehicle as a whole. The first automotive application was the Rumpler Tropfenwagen, another early example was the 1923 Tatra 11 later followed by the Mercedes 130H/150H/170H, the Standard Superior, the pre-facelift Volkswagen Beetle and most of its derivatives, the Chevrolet Corvair, and the roll-over prone M151 jeep amongst others.

A de Dion axle is a form of non-independent automobile suspension. It is a considerable improvement over the swing axle, Hotchkiss drive, or live axle. Because it plays no part in transmitting power to the drive wheels, it is sometimes called a "dead axle".

Body roll is the axial rotation of a vehicle’s body towards the outside of a turn. Body roll occurs because the compliance in vehicle suspension allows the vehicle body, which sits upon the suspension, to lean in the direction of the perceived centrifugal force acting upon the vehicle.

In automotive suspension, a control arm, also known as an A-arm, is a hinged suspension link between the chassis and the suspension upright or hub that carries the wheel. In simple terms, it governs a wheel's vertical travel, allowing it to move up or down when driving over bumps, into potholes, or otherwise reacting to the irregularities of a road surface. Most control arms form the lower link of a suspension. Control arms play a crucial role in the suspension system of a vehicle. They help to keep the wheels aligned and maintain proper tire contact with the road, which is essential for safety and stability.

Self-levelling refers to an automobile suspension system that maintains a constant ride height of the vehicle above the road, regardless of load.

A Corvette leaf spring is a type of independent suspension that utilizes a fiber-reinforced plastic (FRP) mono-leaf spring instead of more conventional coil springs. It is named after the Chevrolet Corvette, the American sports car for which it was originally developed and first utilized. A notable characteristic of this suspension configuration is the mounting of the mono-leaf spring such that it can serve as both ride spring and anti-roll spring. In contrast to many applications of leaf springs in automotive suspension designs, this type does not use the spring as a locating link. While this suspension type is most notably associated with several generations of the Chevrolet Corvette the design has been used in other production General Motors cars, as well as vehicles from Volvo Cars and Mercedes-Benz Sprinter van. Fiat produced cars with a similar configuration, using a multi-leaf steel spring in place of the FRP mono-leaf spring.

An active suspension is a type of automotive suspension that uses an onboard control system to control the vertical movement of the vehicle's wheels and axles relative to the chassis or vehicle frame, rather than the conventional passive suspension that relies solely on large springs to maintain static support and dampen the vertical wheel movements caused by the road surface. Active suspensions are divided into two classes: true active suspensions, and adaptive or semi-active suspensions. While adaptive suspensions only vary shock absorber firmness to match changing road or dynamic conditions, active suspensions use some type of actuator to raise and lower the chassis independently at each wheel.

The following outline is provided as an overview of and topical guide to automobiles:

Bump steer is the term for the tendency of the wheel of a car to steer itself as it moves through the suspension stroke.

Automotive suspension design is an aspect of automotive engineering, concerned with designing the suspension for cars and trucks. Suspension design for other vehicles is similar, though the process may not be as well established.

The twist-beam rear suspension is a type of automobile suspension based on a large H- or C-shaped member. The front of the H attaches to the body via rubber bushings, and the rear of the H carries each stub-axle assembly, on each side of the car. The cross beam of the H holds the two trailing arms together, and provides the roll stiffness of the suspension, by twisting as the two trailing arms move vertically, relative to each other.

A platform chassis is a form of vehicle frame / automobile chassis, constructed as a flat plate or platform, sometimes integrating a backbone or frame-structure with a vehicle's floor-pan.