A wheel is a circular component that is intended to rotate on an axle bearing. The wheel is one of the key components of the wheel and axle which is one of the six simple machines. Wheels, in conjunction with axles, allow heavy objects to be moved easily facilitating movement or transportation while supporting a load, or performing labor in machines. Wheels are also used for other purposes, such as a ship's wheel, steering wheel, potter's wheel, and flywheel.

A tire or tyre is a ring-shaped component that surrounds a wheel's rim to transfer a vehicle's load from the axle through the wheel to the ground and to provide traction on the surface over which the wheel travels. Most tires, such as those for automobiles and bicycles, are pneumatically inflated structures, which also provide a flexible cushion that absorbs shock as the tire rolls over rough features on the surface. Tires provide a footprint, called a contact patch, that is designed to match the weight of the vehicle with the bearing strength of the surface that it rolls over by providing a bearing pressure that will not deform the surface excessively.

A spoke is one of some number of rods radiating from the center of a wheel, connecting the hub with the round traction surface.

A bicycle brake reduces the speed of a bicycle or prevents it from moving. The three main types are: rim brakes, disc brakes, and drum brakes.

A bicycle wheel is a wheel, most commonly a wire wheel, designed for a bicycle. A pair is often called a wheelset, especially in the context of ready built "off the shelf" performance-oriented wheels.

A touring bicycle is a bicycle designed or modified to handle bicycle touring. To make the bikes sufficiently robust, comfortable and capable of carrying heavy loads, special features may include a long wheelbase, frame materials that favor flexibility over rigidity, heavy duty wheels, and multiple mounting points.

The wheel size for a motor vehicle or similar wheel has a number of parameters.

The caster angle or castor angle is the angular displacement of the steering axis from the vertical axis of a steered wheel in a car, motorcycle, bicycle, other vehicle or a vessel, as seen from the side of the vehicle. The steering axis in a car with dual ball joint suspension is an imaginary line that runs through the center of the upper ball joint to the center of the lower ball joint, or through the center of the kingpin for vehicles having a kingpin.

29ers or two-niners are mountain bikes and hybrid bikes that are built to use 700c or 622 mm ISO wheels, commonly called 29″ wheels. Most mountain bikes once used ISO 559 mm wheels, commonly called 26″ wheels. The ISO 622 mm wheel is typically also used for road-racing, trekking, cyclo-cross, touring and hybrid bicycles. In some countries, mainly in Continental Europe, ISO 622 mm wheels are commonly called 28″ wheels or "28 Incher".

Wheelbuilding is the process of assembling wire wheels. The components of a wire wheel are the rim, spokes, nipples, and hub.

The spinner on automobile wheels historically refers to knock-off hub nuts or center caps. They may be the actual, or intended to simulate, the design used on antique vehicles or vintage sports cars. A "spinner wheel" in contemporary usage is a type of hubcap or inner wheel ornament, that spins independently inside of a wheel itself when the vehicle is in motion, and continues to spin once the vehicle has come to a stop.

Zipp is an American company that is best known for designing, manufacturing, and marketing carbon-composite bicycle wheels for road cycling, triathlons, track racing, and mountain biking. The company's product range also includes handlebars, stems, seat posts, tires, inner tubes, handlebar tape, and bags.

The rim is the "outer edge of a wheel, holding the tire". It makes up the outer circular design of the wheel on which the inside edge of the tire is mounted on vehicles such as automobiles. For example, on a bicycle wheel the rim is a large hoop attached to the outer ends of the spokes of the wheel that holds the tire and tube. In cross-section, the rim is deep in the center and shallow at the outer edges, thus forming a "U" shape that supports the bead of the tire casing.

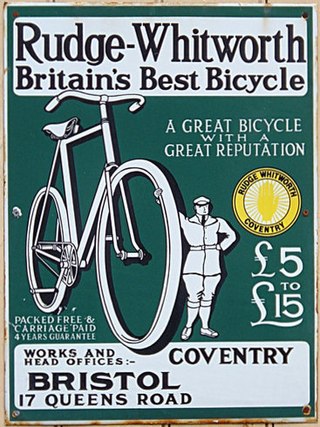

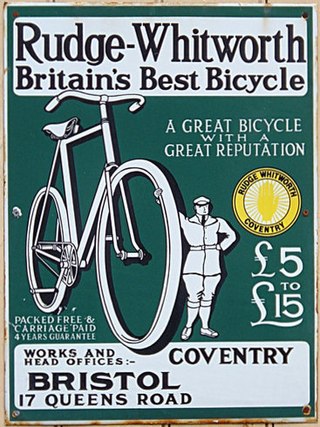

Rudge Whitworth Cycles was a British bicycle, bicycle saddle, motorcycle and sports car wheel manufacturer that resulted from the merger of two bicycle manufacturers in 1894, Whitworth Cycle Co. of Birmingham, founded by Charles Henry Pugh and his two sons Charles Vernon and John, and Rudge Cycle Co. of Coventry.

Ruote Borrani S.p.A. is an Italian manufacturer of automobile and motorcycle wheels. They are known for supplying Rudge-Whitworth design centerlocking wire wheels to many Italian racing cars, sports cars and luxury cars.

A motorcycle tyre is the outer part of motorcycle wheel, attached to the rim, providing traction, resisting wear, absorbing surface irregularities, and allowing the motorcycle to turn via countersteering. The two tyres' contact patches are the motorcycle's connection to the ground, and so are fundamental to the motorcycle's suspension behaviour, and critically affect safety, braking, fuel economy, noise, and rider comfort.

Mountain bike trials, also known as observed trials, is a discipline of mountain biking in which the rider attempts to pass through an obstacle course without setting foot to ground. Derived from motorcycle trials, it originated in Catalonia, Spain as trialsín and is said to have been invented by Pere Pi, the father of Ot Pi, a world champion motorcycle trials rider. Pi's father had wanted his son to learn motorcycle trials by practicing on an ordinary bicycle.

Motorcyclewheels are made to cope with radial and axial forces. They also provide a way of mounting other critical components such as the brakes, final drive and suspension. Wheels, and anything directly connected to them, are considered to be unsprung mass. Traditionally motorcycles used wire-spoked wheels with inner tubes and pneumatic tyres. Although cast wheels were first used on a motorcycle in 1927, it would not be until the 1970s that mainstream manufacturers would start to introduce cast wheels on their roadgoing motorcycles. Spoked wheels are usually made using steel spokes with steel or aluminium rims. Cast wheels are predominantly made from an aluminium-alloy, but can also be made from more-exotic materials, such as magnesium content alloy or carbon fibre.

A centerlock wheel is a type of automobile wheel in which the wheel is fastened to the axle using a single, central nut, instead of the more common ring of 4 or 5 lug nuts or bolts.