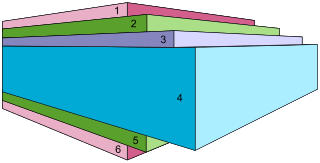

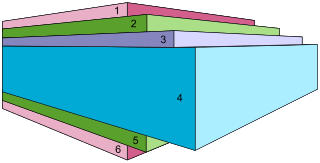

Corrugated fiberboard, corrugated cardboard, or corrugated is a type of packaging material consisting of a fluted corrugated sheet and one or two flat linerboards. It is made on "flute lamination machines" or "corrugators" and is used for making corrugated boxes. The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over 0.25 millimetres (0.01 in) thick.

Paperboard is a thick paper-based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker than paper and has certain superior attributes such as foldability and rigidity. According to ISO standards, paperboard is a paper with a grammage above 250 g/m2, but there are exceptions. Paperboard can be single- or multi-ply.

A carton is a box or container usually made of liquid packaging board, paperboard and sometimes of corrugated fiberboard. Many types of cartons are used in packaging. Sometimes a carton is also called a box.

Cardboard boxes are industrially prefabricated boxes, primarily used for packaging goods and materials. Specialists in industry seldom use the term cardboard because it does not denote a specific material. The term cardboard may refer to a variety of heavy paper-like materials, including card stock, corrugated fiberboard, and paperboard. Cardboard boxes can be readily recycled.

Kraft paper or kraft is paper or paperboard (cardboard) produced from chemical pulp produced in the kraft process.

Coated paper is paper that has been coated by a mixture of materials or a polymer to impart certain qualities to the paper, including weight, surface gloss, smoothness, or reduced ink absorbency. Various materials, including kaolinite, calcium carbonate, bentonite, and talc, can be used to coat paper for high-quality printing used in the packaging industry and in magazines.

Molded pulp or molded fiber is a packaging material, that is typically made from recycled paperboard and/or newsprint. It is used for protective packaging or for food service trays and beverage carriers. Other typical uses are end caps, trays, plates, bowls and clamshell containers.

The folding carton created the packaging industry as it is known today, beginning in the late 19th century. The process involves folding carton made of paperboard that is printed, laminated, cut, then folded and glued. The cartons are shipped flat to a packager, which has its own machinery to fold the carton into its final shape as a container for a product. Some styles of folding cartons can be made of E-flute or micro-flute corrugated fiberboard.

Cardboard is a generic term for a heavy-duty paper.

Paper is a thin sheet material produced by mechanically or chemically processing cellulose fibres derived from wood, rags, grasses, herbivore dung, or other vegetable sources in water. Once the water is drained through a fine mesh leaving the fibre evenly distributed on the surface, it can be pressed and dried.

Deinking is the industrial process of removing printing ink from paperfibers of recycled paper to make deinked pulp.

Liquid packaging board is a multi-ply paperboard with high stiffness, strong wet sizing and a high barrier coating, e.g. plastic. Only virgin paper fibers are used. The barrier coating must hold the liquid and prevent migration of air and flavors through the paperboard.

Electrical insulation papers are paper types that are used as electrical insulation in many applications due to pure cellulose having outstanding electrical properties. Cellulose is a good insulator and is also polar, having a dielectric constant significantly greater than one. Electrical paper products are classified by their thickness, with tissue considered papers less than 1.5 mils (0.0381 mm) thickness, and board considered more than 20 mils (0.508 mm) thickness.

White-lined chipboard is a grade of paperboard typically made from layers of waste paper or recycled fibers. Most often it comes with two to three layers of coating on the top and one layer on the reverse side. Because of its recycled content it will be grey from the inside. The main end use for this type of board is for packaging of frozen or chilled food, cereals, shoes, toys and others.

Folding boxboard, also referred to as FBB or by the DIN Standard 19303 codes of GC or UC, is a paperboard grade made up of multiple layers of chemical and mechanical pulp. This grade is made up of mechanical pulp in between two layers of chemical pulp. The top layer is of bleached chemical pulp with an optional pigment coating. This is a low-density material with high stiffness and a slightly yellow colour, mainly on the inside. The major end uses of folding boxboard are health and beauty products, frozen, chilled and other foods, confectionaries, pharmaceuticals, graphical uses and cigarettes.

Solid bleached board (SBB) or solid bleached sulphate (SBS) is a virgin fibre grade of paperboard.

Clearwater Paper Corporation is an American pulp and paperboard manufacturer. The company was created on December 9, 2008, via a spin-off from Potlatch Corporation and is headquartered in Spokane, Washington.

Nippon Paper Industries Co., Ltd. is a Japanese paper manufacturing company. The company's stock is listed on the Tokyo and Nagoya Stock Exchange and on the Osaka Securities Exchange. The stock is also constituent of the Nikkei 225 stock index.

Cardboard is a generic term for heavy paper-based products. The construction can range from a thick paper known as paperboard to corrugated fiberboard which is made of multiple plies of material. Natural cardboards can range from grey to light brown in color, depending on the specific product; dyes, pigments, printing, and coatings are available.

Official Board Markets was a weekly trade publication for independent and integrated paperboard converters and mills, packaging buyers, paper recyclers, packaging end-users, and paper brokers. It was in circulation between 1925 and 2012.