Cavitation in fluid mechanics and engineering normally refers to the phenomenon in which the static pressure of a liquid reduces to below the liquid's vapour pressure, leading to the formation of small vapor-filled cavities in the liquid. When subjected to higher pressure, these cavities, called "bubbles" or "voids", collapse and can generate shock waves that may damage machinery. These shock waves are strong when they are very close to the imploded bubble, but rapidly weaken as they propagate away from the implosion. Cavitation is a significant cause of wear in some engineering contexts. Collapsing voids that implode near to a metal surface cause cyclic stress through repeated implosion. This results in surface fatigue of the metal, causing a type of wear also called "cavitation". The most common examples of this kind of wear are to pump impellers, and bends where a sudden change in the direction of liquid occurs. Cavitation is usually divided into two classes of behavior: inertial cavitation and non-inertial cavitation.

Ultrasound is sound with frequencies greater than 20 kilohertz. This frequency is the approximate upper audible limit of human hearing in healthy young adults. The physical principles of acoustic waves apply to any frequency range, including ultrasound. Ultrasonic devices operate with frequencies from 20 kHz up to several gigahertz.

Cell disruption is a method or process for releasing biological molecules from inside a cell.

Degassing, also known as degasification, is the removal of dissolved gases from liquids, especially water or aqueous solutions. There are numerous methods for removing gases from liquids.

Supercritical fluid extraction (SFE) is the process of separating one component (the extractant) from another (the matrix) using supercritical fluids as the extracting solvent. Extraction is usually from a solid matrix, but can also be from liquids. SFE can be used as a sample preparation step for analytical purposes, or on a larger scale to either strip unwanted material from a product (e.g. decaffeination) or collect a desired product (e.g. essential oils). These essential oils can include limonene and other straight solvents. Carbon dioxide (CO2) is the most used supercritical fluid, sometimes modified by co-solvents such as ethanol or methanol. Extraction conditions for supercritical carbon dioxide are above the critical temperature of 31 °C and critical pressure of 74 bar. Addition of modifiers may slightly alter this. The discussion below will mainly refer to extraction with CO2, except where specified.

Sonication is the act of applying sound energy to agitate particles in a sample, for various purposes such as the extraction of multiple compounds from plants, microalgae and seaweeds. Ultrasonic frequencies (> 20 kHz) are usually used, leading to the process also being known as ultrasonication or ultra-sonication.

Ultrasonic cleaning is a process that uses ultrasound to agitate a fluid, with a cleaning effect. Ultrasonic cleaners come in a variety of sizes, from small desktop units with an internal volume of less than 0.5 litres (0.13 US gal), to large industrial units with volumes approaching 1,000 litres.

In chemistry, the study of sonochemistry is concerned with understanding the effect of ultrasound in forming acoustic cavitation in liquids, resulting in the initiation or enhancement of the chemical activity in the solution. Therefore, the chemical effects of ultrasound do not come from a direct interaction of the ultrasonic sound wave with the molecules in the solution.

A molecularly imprinted polymer (MIP) is a polymer that has been processed using the molecular imprinting technique which leaves cavities in the polymer matrix with an affinity for a chosen "template" molecule. The process usually involves initiating the polymerization of monomers in the presence of a template molecule that is extracted afterwards, leaving behind complementary cavities. These polymers have affinity for the original molecule and have been used in applications such as chemical separations, catalysis, or molecular sensors. Published works on the topic date to the 1930s.

A bubble is a globule of a gas substance in a liquid. In the opposite case, a globule of a liquid in a gas, is called a drop. Due to the Marangoni effect, bubbles may remain intact when they reach the surface of the immersive substance.

Sonophoresis also known as phonophoresis, is a method that utilizes ultrasound to enhance the delivery of topical medications through the stratum corneum, to the epidermis and dermis. Sonophoresis allows for the enhancement of the permeability of the skin along with other modalities, such as iontophoresis, to deliver drugs with lesser side effects. Currently, sonophoresis is used widely in transdermal drug delivery, but has potential applications in other sectors of drug delivery, such as the delivery of drugs to the eye and brain.

An ultrasonic horn is a tapering metal bar commonly used for augmenting the oscillation displacement amplitude provided by an ultrasonic transducer operating at the low end of the ultrasonic frequency spectrum. The device is necessary because the amplitudes provided by the transducers themselves are insufficient for most practical applications of power ultrasound. Another function of the ultrasonic horn is to efficiently transfer the acoustic energy from the ultrasonic transducer into the treated media, which may be solid or liquid. Ultrasonic processing of liquids relies of intense shear forces and extreme local conditions generated by acoustic cavitation.

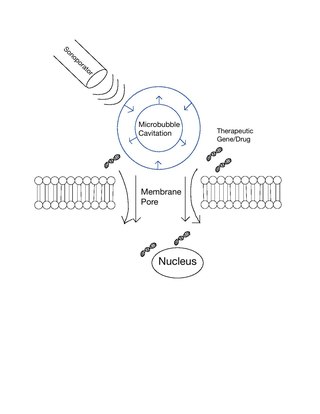

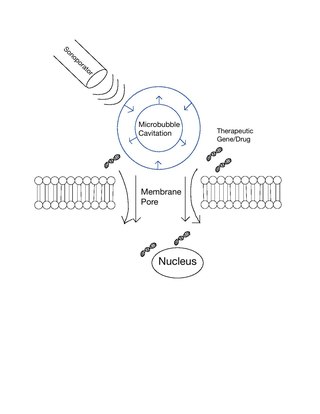

Sonoporation, or cellular sonication, is the use of sound in the ultrasonic range for increasing the permeability of the cell plasma membrane. This technique is usually used in molecular biology and non-viral gene therapy in order to allow uptake of large molecules such as DNA into the cell, in a cell disruption process called transfection or transformation. Sonoporation employs the acoustic cavitation of microbubbles to enhance delivery of these large molecules. The exact mechanism of sonoporation-mediated membrane translocation remains unclear, with a few different hypotheses currently being explored.

Extraction in chemistry is a separation process consisting of the separation of a substance from a matrix. The distribution of a solute between two phases is an equilibrium condition described by partition theory. This is based on exactly how the analyte moves from the initial solvent into the extracting solvent. The term washing may also be used to refer to an extraction in which impurities are extracted from the solvent containing the desired compound.

Single cell oil, also known as Microbial oil consists of the intracellular storage lipids, triacyglycerols. It is similar to vegetable oil, another biologically produced oil. They are produced by oleaginous microorganisms, which is the term for those bacteria, molds, algae and yeast, which can accumulate 20% to 80% lipids of their biomass. The accumulation of lipids take place by the end of logarithmic phase and continues during station phase until carbon source begins to reduce with nutrition limitation.

Microbes can be damaged or killed by elements of their physical environment such as temperature, radiation, or exposure to chemicals; these effects can be exploited in efforts to control pathogens, often for the purpose of food safety.

Sonodynamic therapy (SDT) is a noninvasive treatment, often used for tumor irradiation, that utilizes a sonosensitizer and the deep penetration of ultrasound to treat lesions of varying depths by reducing target cell number and preventing future tumor growth. Many existing cancer treatment strategies cause systemic toxicity or cannot penetrate tissue deep enough to reach the entire tumor; however, emerging ultrasound stimulated therapies could offer an alternative to these treatments with their increased efficiency, greater penetration depth, and reduced side effects. Sonodynamic therapy could be used to treat cancers and other diseases, such as atherosclerosis, and diminish the risk associated with other treatment strategies since it induces cytotoxic effects only when externally stimulated by ultrasound and only at the cancerous region, as opposed to the systemic administration of chemotherapy drugs.

Ultrasonic antifouling is a technology that uses high frequency sound (ultrasound) to prevent or reduce biofouling on underwater structures, surfaces, and medium. Ultrasound is just high frequency sound. Ultrasound has the same physical properties as human-audible sound. The method has two primary forms: sub-cavitation intensity and cavitation intensity. Sub-cavitation methods create high frequency vibrations, whilst cavitation methods cause more destructive microscopic pressure changes. Both methods inhibit or prevent biofouling by algae and other single-celled organisms.

Accelerated solvent extraction (ASE), also known as pressurized solvent extraction (PSE), is a method for extracting various chemicals from a complex solid or semisolid sample matrix. The process uses high temperature and pressure, which results in the extraction taking less time and requiring less solvent, and possibly also giving better analyte recovery, than traditional methods that use less extreme conditions. The elevated temperature is employed to increase extraction efficiency of the analyte of interest and the elevated pressure is used to keep the solvent in a liquid state as the temperature is increased above its boiling point. An automated system for the process was developed by Dionex, a company owned by Thermo Fisher Scientific.

Ozone micro/nano-bubble technology overcomes the limitation of ozone oxidation and mass transfer of ozone and its utilization. It improves the oxidation efficiency of ozone. Ozone micro/nano-bubble technology improves the disinfectant capacity of ozone.