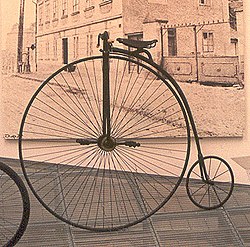

Bicycle drivetrain systems are used to transmit power on bicycles, tricycles, quadracycles, unicycles, or other human-powered vehicles from the riders to the drive wheels. Most also include some type of a mechanism to convert speed and torque via gear ratios.