Vulcan Iron Works was the name of several iron foundries in both England and the United States during the Industrial Revolution and, in one case, lasting until the mid-20th century. Vulcan, the Roman god of fire and smithery, was a popular namesake for these foundries.

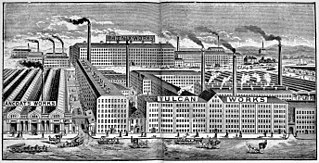

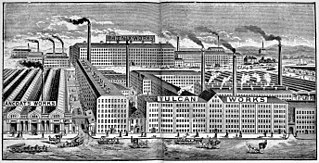

Platt Brothers, also known as Platt Bros & Co Ltd, was a British company based at Werneth in Oldham, North West England. The company manufactured textile machinery and were iron founders and colliery proprietors. By the end of the 19th century, the company had become the largest textile machinery manufacturer in the world, employing more than 12,000 workers.

Howard & Bullough was a firm of textile machine manufacturers in Accrington, Lancashire. The company was the world's major manufacturer of power looms in the 1860s.

Mather & Platt is the name of several large engineering firms in Europe, South Africa and Asia that are subsidiaries of Wilo SE, Germany or were founded by former employees. The original company was founded in the Newton Heath area of Manchester, England, where it was a major employer. That firm continues as a food processing and packaging business, trading as M & P Engineering in Trafford Park, Manchester.

The Lancashire Loom was a semi-automatic power loom invented by James Bullough and William Kenworthy in 1842. Although it is self-acting, it has to be stopped to recharge empty shuttles. It was the mainstay of the Lancashire cotton industry for a century.

Tweedales and Smalley was a manufacturer of textile machinery in Castleton, Rochdale, Greater Manchester, in England. It specialised in ring spinning frames mainly for export.

Ring spinning is a spindle-based method of spinning fibres, such as cotton, flax or wool, to make a yarn. The ring frame developed from the throstle frame, which in its turn was a descendant of Arkwright's water frame. Ring spinning is a continuous process, unlike mule spinning which uses an intermittent action. In ring spinning, the roving is first attenuated by using drawing rollers, then spun and wound around a rotating spindle which in its turn is contained within an independently rotating ring flyer. Traditionally ring frames could only be used for the coarser counts, but they could be attended by semi-skilled labour.

John Platt was an English manufacturer of textile machinery and Liberal politician.

John Hetherington & Sons was a textile machinery manufacturer from Ancoats, Manchester in England, founded in 1830

In the recession of the 1930s, Platt Brothers, Howard and Bullough, Brooks and Doxey, Asa Lees, Dobson and Barlow, Joseph Hibbert, John Hetherington and Tweedales and Smalley merged to become Textile Machinery Makers Ltd., but the individual units continued to trade under their own names until 1970, when they were rationalised into one company called Platt UK Ltd. In 1991 the company name changed to Platt Saco Lowell. The Globe works closed in 1993.

Asa Lees was a firm of textile machine manufacturers in Oldham, Lancashire. Their headquarters was the Soho Iron Works, Greenacres. It was second only in size to Platt Brothers.

Dobson and Barlow were manufacturers of textile machinery with works in Bolton, Greater Manchester. Isaac Dobson (1767–1833) founded the company in 1790 and by 1850 Dobson in partnership with Peter Rothwell had premises in Blackhorse Street which produced mules for cotton spinning. The company moved to a larger factory in Kay Street which had 1,600 workers in 1860.

Butterworth and Dickinson were textile machinery manufacturers in Burnley, Lancashire, England. Known as "Butts and Dicks", the company made looms that were exported around the world.

Joseph Hibbert was a textile machinery manufacturer from Darwen, Lancashire in UK. The Iron, Brass and Copper Works was in Bridge Street.

Taylor, Lang & Co. was a textile machinery manufacturer based in Stalybridge, Greater Manchester, England.

May Mill was a cotton spinning mill in Pemberton, Wigan, Greater Manchester, England. Historically in Lancashire, it was built in 1889. It was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1962–63 to produce carpet fibre, which it continued to do until its closure on 17 October 1980.

Harp Mill was a former cotton spinning mill in the Castleton, Rochdale, Greater Manchester, England. Queensway, Castleton was a hub of cotton mills including the three 't', Th'Arrow, Th'Harp, and Th'Ensor. The 1908 Castleton map includes: Marland Cotton Mill, Castleton Cotton Mill, Globe Works, Arrow Cotton Mill, Harp Cotton Mill, Globe Leather Works, Castleton Size Works and Castleton Iron Works. Th'Harp was built in 1908 for the Harp Doubling Company and was taken over by the Lancashire Cotton Corporation in 1938. The mill closed in 1958, and was sold to the hosiery manufacturer N. Corah Ltd.

Albion Mill is a former industrial building in Manchester, United Kingdom. It occupies the site of a former cotton mill and ironworks.

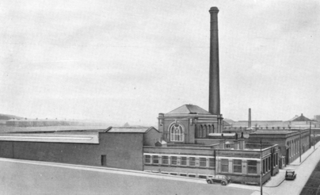

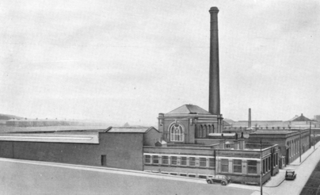

The Globe Works is a former industrial works in Accrington, Lancashire, England, that following refurbishment contains rented offices and conference rooms and is known as the Globe Centre. The centre is made up of the remainder of The Globe Works, which created machinery and looms for the cotton industry under management of the Howard & Bullough firm.

The technique of sizing a warp was mechanised during the nineteenth century when William Radcliffe and his assistant Thomas Johnson invented the sizing machine. The purpose of introducing size, which is either a starchy substance for cotton or gelatinous mixture for woollen fibre, is to reduce the chances of threads fraying and breaking due to the friction of the weaving process. The size stiffens the thread and helps the fibres lie closely together. Many recipes for size can be found in textile manufacturing books. The recipes include flour, sago, china clay, types of soap, fats and some chemicals.