Concrete is a composite material composed of aggregate bonded together with a fluid cement that cures over time. Concrete is the second-most-used substance in the world after water, and is the most widely used building material. Its usage worldwide, ton for ton, is twice that of steel, wood, plastics, and aluminium combined.

Reinforced concrete, also called ferroconcrete, is a composite material in which concrete's relatively low tensile strength and ductility are compensated for by the inclusion of reinforcement having higher tensile strength or ductility. The reinforcement is usually, though not necessarily, steel bars (rebar) and is usually embedded passively in the concrete before the concrete sets. However, post-tensioning is also employed as a technique to reinforce the concrete. In terms of volume used annually, it is one of the most common engineering materials. In corrosion engineering terms, when designed correctly, the alkalinity of the concrete protects the steel rebar from corrosion.

Rebar, known when massed as reinforcing steel or reinforcement steel, is a steel bar used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has low tensile strength. Rebar significantly increases the tensile strength of the structure. Rebar's surface features a continuous series of ribs, lugs or indentations to promote a better bond with the concrete and reduce the risk of slippage.

Prestressed concrete is a form of concrete used in construction. It is substantially "prestressed" (compressed) during production, in a manner that strengthens it against tensile forces which will exist when in service.

Tilt-up,tilt-slab or tilt-wall is a type of building and a construction technique using concrete. Though it is a cost-effective technique with a shorter completion time, poor performance in earthquakes has mandated significant seismic retrofit requirements in older buildings.

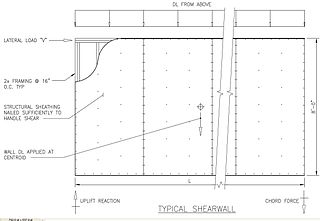

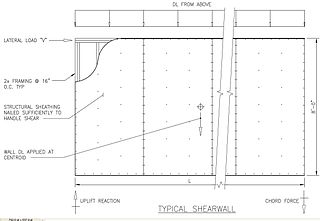

In structural engineering, a shear wall is a two-dimensional vertical element of a system that is designed to resist in-plane lateral forces, typically wind and seismic loads.

Falsework consists of temporary structures used in construction to support a permanent structure until its construction is sufficiently advanced to support itself. For arches, this is specifically called centering. Falsework includes temporary support structures for formwork used to mold concrete in the construction of buildings, bridges, and elevated roadways.

A concrete slab is a common structural element of modern buildings, consisting of a flat, horizontal surface made of cast concrete. Steel-reinforced slabs, typically between 100 and 500 mm thick, are most often used to construct floors and ceilings, while thinner mud slabs may be used for exterior paving (see below).

Formwork is molds into which concrete or similar materials are either precast or cast-in-place. In the context of concrete construction, the falsework supports the shuttering molds. In specialty applications formwork may be permanently incorporated into the final structure, adding insulation or helping reinforce the finished structure.

Structural steel is a category of steel used for making construction materials in a variety of shapes. Many structural steel shapes take the form of an elongated beam having a profile of a specific cross section. Structural steel shapes, sizes, chemical composition, mechanical properties such as strengths, storage practices, etc., are regulated by standards in most industrialized countries.

Precast concrete is a construction product produced by casting concrete in a reusable mold or "form" which is then cured in a controlled environment, transported to the construction site and maneuvered into place; examples include precast beams, and wall panels for tilt up construction. In contrast, cast-in-place concrete is poured into site-specific forms and cured on site.

A hollow core slab, also known as a voided slab, hollow core plank or simply a concrete plank is a precast slab of prestressed concrete typically used in the construction of floors in multi-story apartment buildings. The slab has been especially popular in countries where the emphasis of home construction has been on precast concrete, including Northern Europe and former socialist countries of Eastern Europe. Precast concrete popularity is linked with low-seismic zones and more economical constructions because of fast building assembly, lower self weight, etc.

Fiber-reinforced concrete or fibre-reinforced concrete (FRC) is concrete containing fibrous material which increases its structural integrity. It contains short discrete fibers that are uniformly distributed and randomly oriented. Fibers include steel fibers, glass fibers, synthetic fibers and natural fibers – each of which lend varying properties to the concrete. In addition, the character of fiber-reinforced concrete changes with varying concretes, fiber materials, geometries, distribution, orientation, and densities.

A rebar spacer is a device that secures the reinforcing steel or "rebar" in reinforced concrete structures as the rebar is assembled in place before the final concrete pour. The spacers are left in place during the pouring to keep the rebars in place. After the pour, the spacers become a part of the structure.

Voided biaxial slabs, sometimes called biaxial slabs or voided slabs, are a type of reinforced concrete slab which incorporates air-filled voids to reduce the volume of concrete required. These voids enable cheaper construction and less environmental impact. Another major benefit of the system is its reduction in slab weight compared with regular solid decks. Up to 50% of the slab volume may be removed in voids, resulting in less load on structural members. This also allows increased weight and/or span, since the self-weight of the slab contributes less to the overall load.

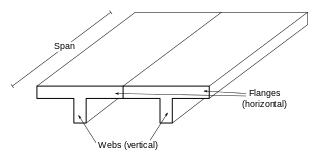

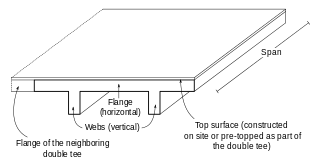

A T-beam, used in construction, is a load-bearing structure of reinforced concrete, wood or metal, with a T-shaped cross section. The top of the T-shaped cross section serves as a flange or compression member in resisting compressive stresses. The web of the beam below the compression flange serves to resist shear stress. When used for highway bridges the beam incorporates reinforcing bars in the bottom of the beam to resist the tensile stresses which occur during bending.

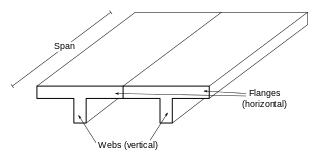

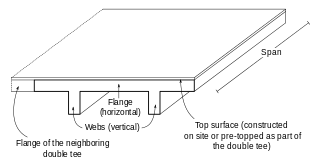

A double tee or double-T beam is a load-bearing structure that resembles two T-beams connected to each other side by side. The strong bond of the flange and the two webs creates a structure that is capable of withstanding high loads while having a long span. The typical sizes of double tees are up to 15 feet (4.6 m) for flange width, up to 5 feet (1.5 m) for web depth, and up to 80 feet (24 m) or more for span length. Double tees are pre-manufactured from prestressed concrete which allows construction time to be shortened.

A waffle slab or two-way joist slab is a concrete slab made of reinforced concrete with concrete ribs running in two directions on its underside. The name waffle comes from the grid pattern created by the reinforcing ribs. Waffle slabs are preferred for spans greater than 40 feet (12 m), as they are much stronger than flat slabs, flat slabs with drop panels, two-way slabs, one-way slabs, and one-way joist slabs.

Post-tensioned stone is a high-performance composite construction material: stone held in compression with tension elements. The tension elements can be connected to the outside of the stone, but more typically uses tendons threaded internally through a duct formed from aligned drilled holes.